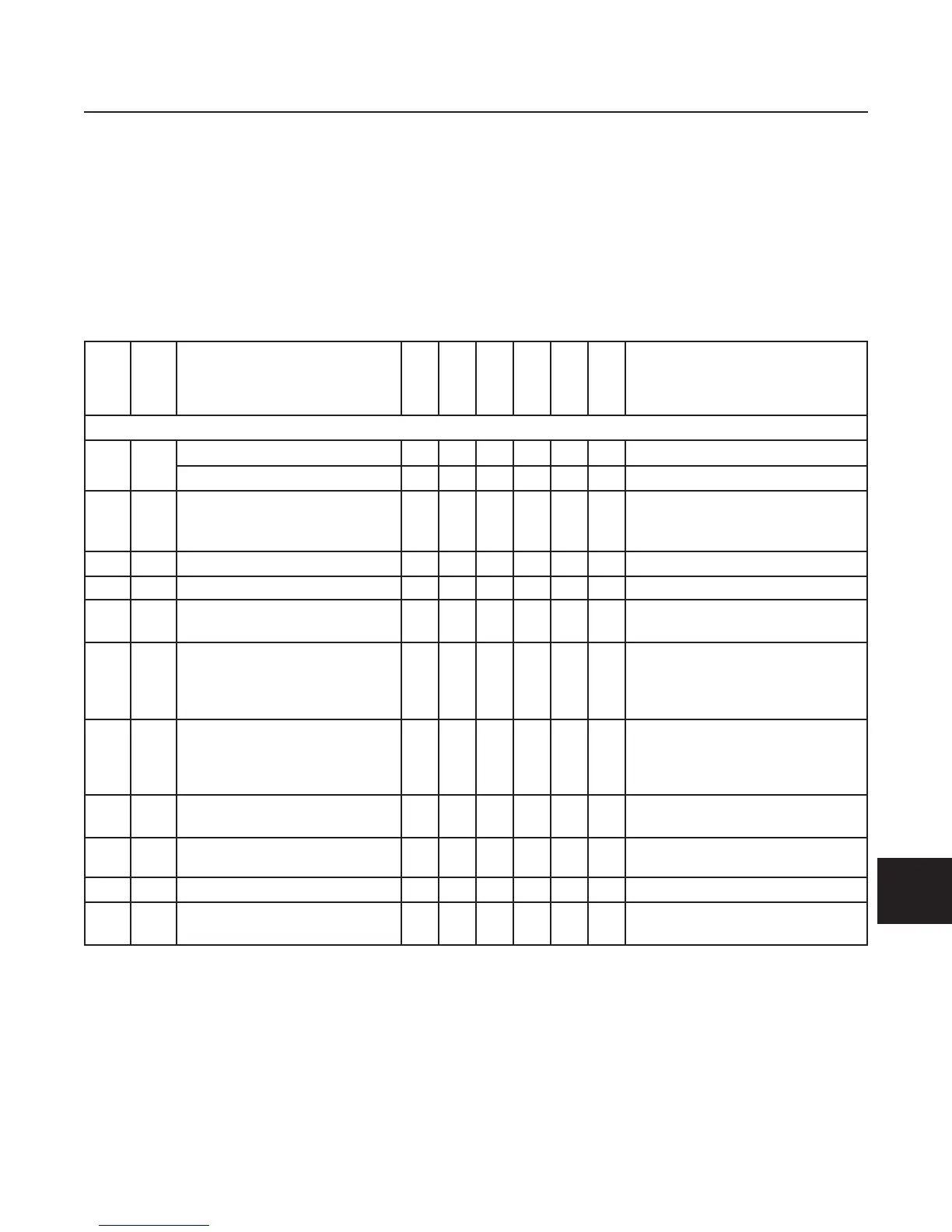

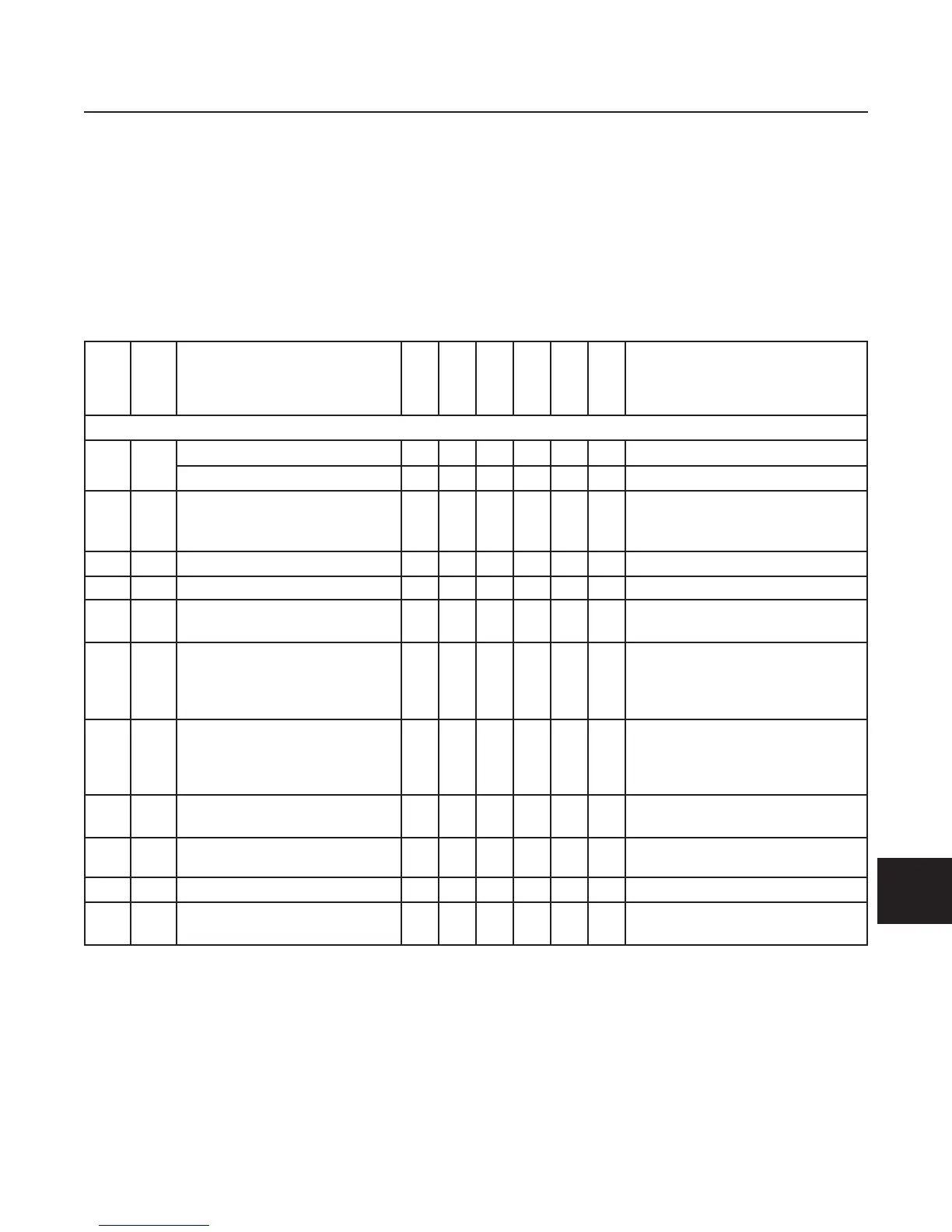

GENERAL

The following charts summarize maintenance to be per-

formed daily, weekly, every two weeks, monthly, every

three months, and annually.

The maintenance charts give recommended hours of

operation between various procedures. Intervals are

based on a 40 hour week.

Reference numbers are keyed to the illustration on

page 11C-3. Footnotes on page 11C-3 give additional

information.

PREVENTIVE MAINTENANCE

SECTION 11C. MAINTENANCE SCHEDULES

11C-1

11C

Ref. Qty. Description

TRACTOR

16 1 c Hydraulic reservoir X Check.

c Hydraulic oil X Change every 500 hours.

17 1 j Charge filter Change the first 25 hours.

Change every 250 hours

thereafter.

18 1 j Return filter

19 1 Tank strainer X

20 1 g Front drive wheel lube X X Change every 250 hours

thereafter.

21 10 Front drive wheel nuts X Torque to 45–50 ft-lbs.

(54–68 N.m). Retorque after

first 20 hours, 250 hours

thereafter.

22 8 Rear steer wheel bolts X Torque to 85–90 ft-lbs.

(115–122 N.m). Retorque after

first 20 hours, 250 hours

thereafter.

23 4 Tire pressure X Front: 20–24 psi (138–165 kPa).

Rear: 6–10 psi (41–69 kPa).

Hydraulic hoses and

tubing X Inspect.

1 Wheel alignment X Check.

24 1 e Brake master cylinder

fluid level X

Annually

Daily

Every 2

Weeks

Every 3

Months

Monthly

Weekly

MAINTENANCE SCHEDULE CHART

Loading...

Loading...