PINION AND RING GEAR BACKLASH

ADJUSTMENT

General

There are two methods described to adjust backlash.

Method “A” and “B” should be reviewed prior to per-

forming the adjustment to determine which will be used.

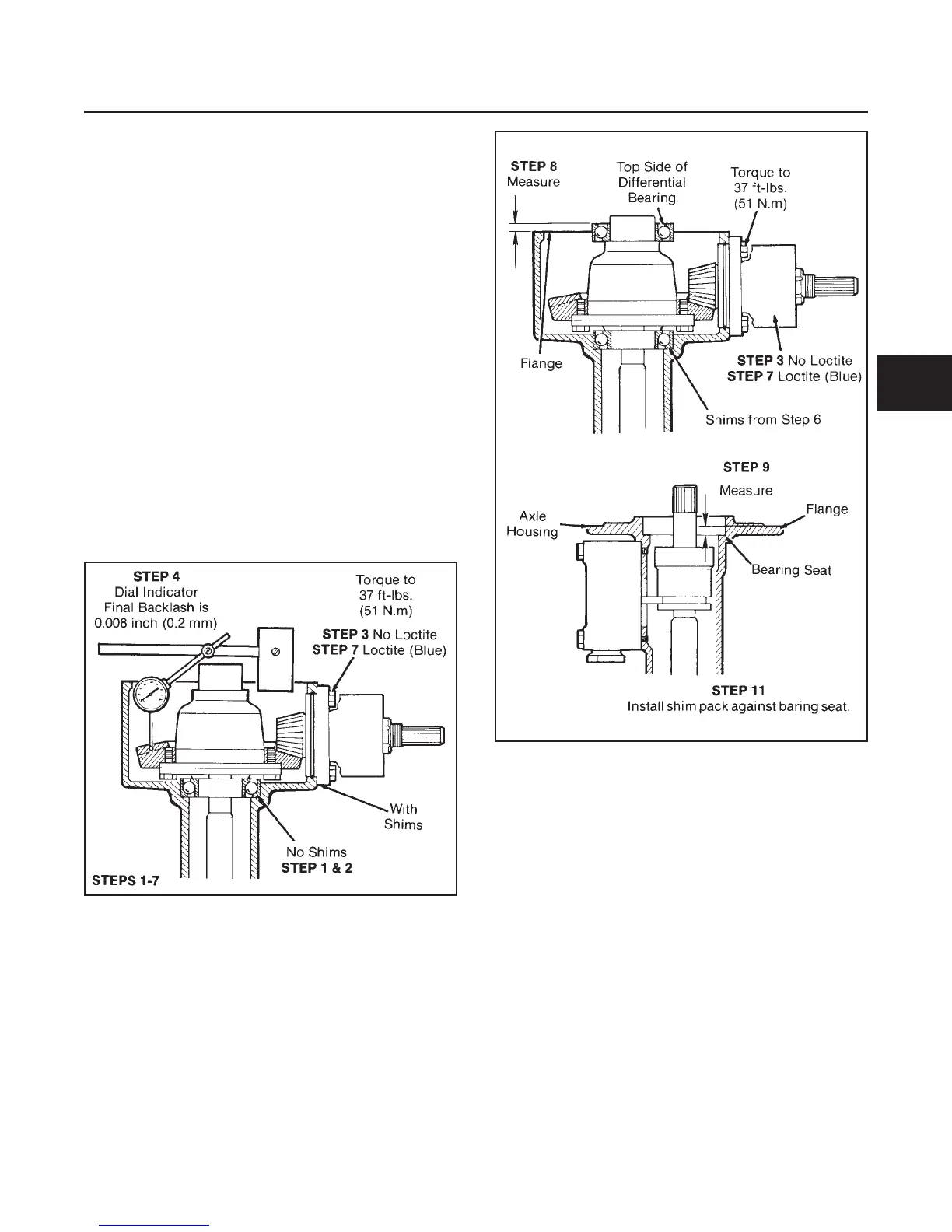

Method “A” (See Figure 4E-11)

1. Press bearings onto the differential assembly.

2. Install the differential assembly with no shims into

the gear case. Make sure bearing is seated in the

bearing bore.

3. Install input bevel pinion with shim pack and torque

to 37 ft-lbs. (51 N.m).

4. Using a dial indicator against a pinion tooth, check

the gear backlash.

5. Subtract backlash of 0.008" (0.2 mm) from the mea-

surement obtained. Build a shim pack equal to the

final dimension.

6. Remove the differential assembly, place the shim

pack in the bearing bore of the gear case.

(See Figure 4E-12)

7. Install differential and input bevel pinion. Apply

Loctite

®

242 (Blue) to the pinion housing bolts and

torque them to 37 ft-lbs. (51 N.m).

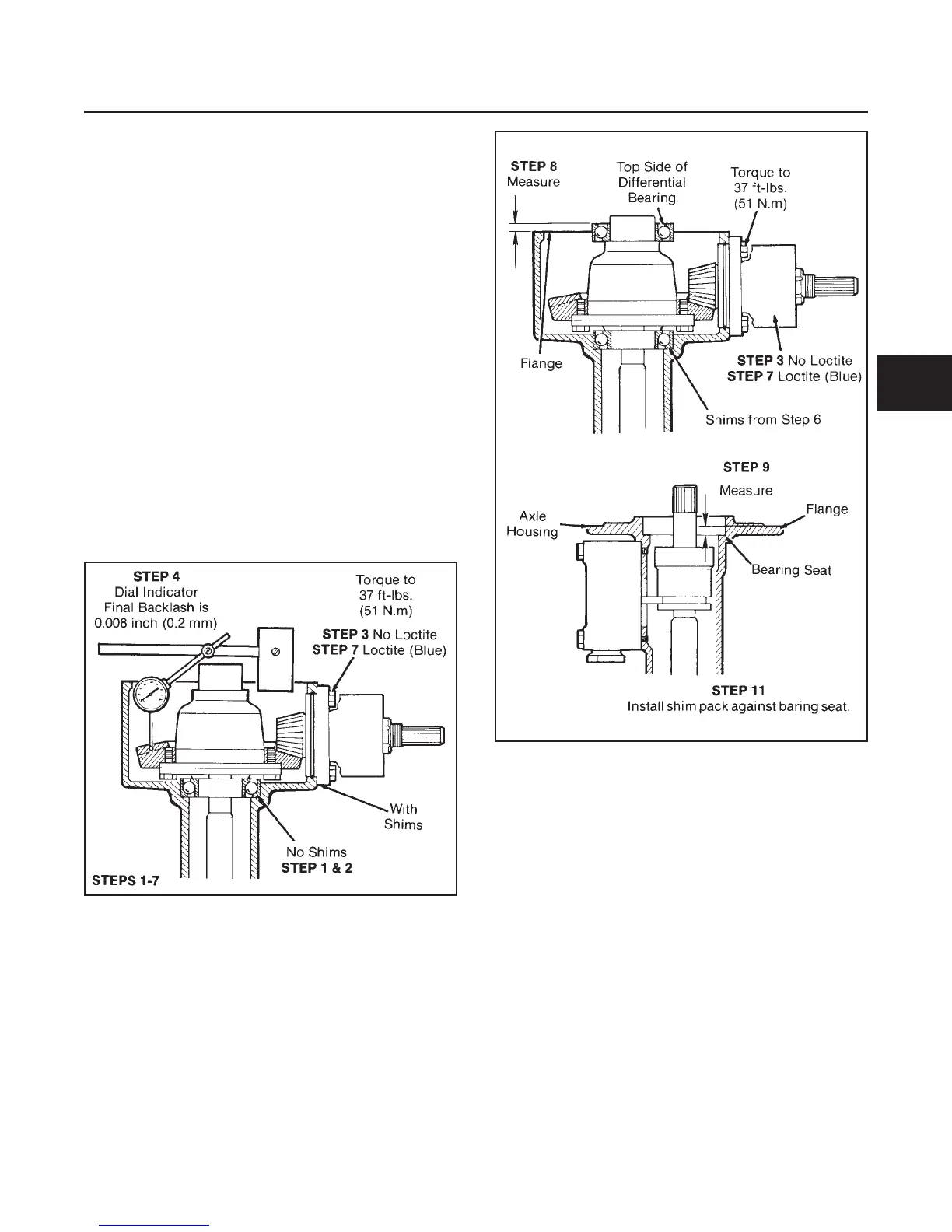

8. Measure the distance from the side of the differ-

ential bearing to the gear case flange surface.

9. In the axle housing, measure the distance from

the flange to the bottom of the bearing seat.

10. Subtract the two measurements. From the answer

add 0.004" (0.1 mm). This is the thickness of the

shim pack.

11. Build a shim pack equal to the thickness obtained

in Step 10 and install it against the bearing seat of

the axle housing.

12. Continue to assemble axle as in Figure 4E-9.

Method “B” (See Figure 4E-11)

1. Press bearings onto the differential assembly.

2. Install the differential assembly with no shims into

the gear case. Make sure bearing is seated in the

bearing bore.

3. Install input bevel pinion with shim pack and torque

to 37 ft-lbs. (51 N.m).

DRIVE TRAIN

SECTION 4E. AXLE

4E-9

4E

Figure 4E-11. Pinion and Ring Gear

Backlash Adjustment

Figure 4E-12. Pinion and Ring Gear

Backlash Adjustment

Loading...

Loading...