4. Using a dial indicator against a pinion tooth, check

the gear backlash.

5. Subtract backlash of 0.008" (0.2 mm) from the

measurement obtained. Build a shim pack equal

to the final dimension.

6. Remove the differential assembly, place the shim

pack in the bearing bore of the gear case.

7. Install differential and input bevel pinion. Apply

Loctite

®

242 (Blue) to the pinion housing bolts and

torque them to 37 ft-lbs. (51 N.m).

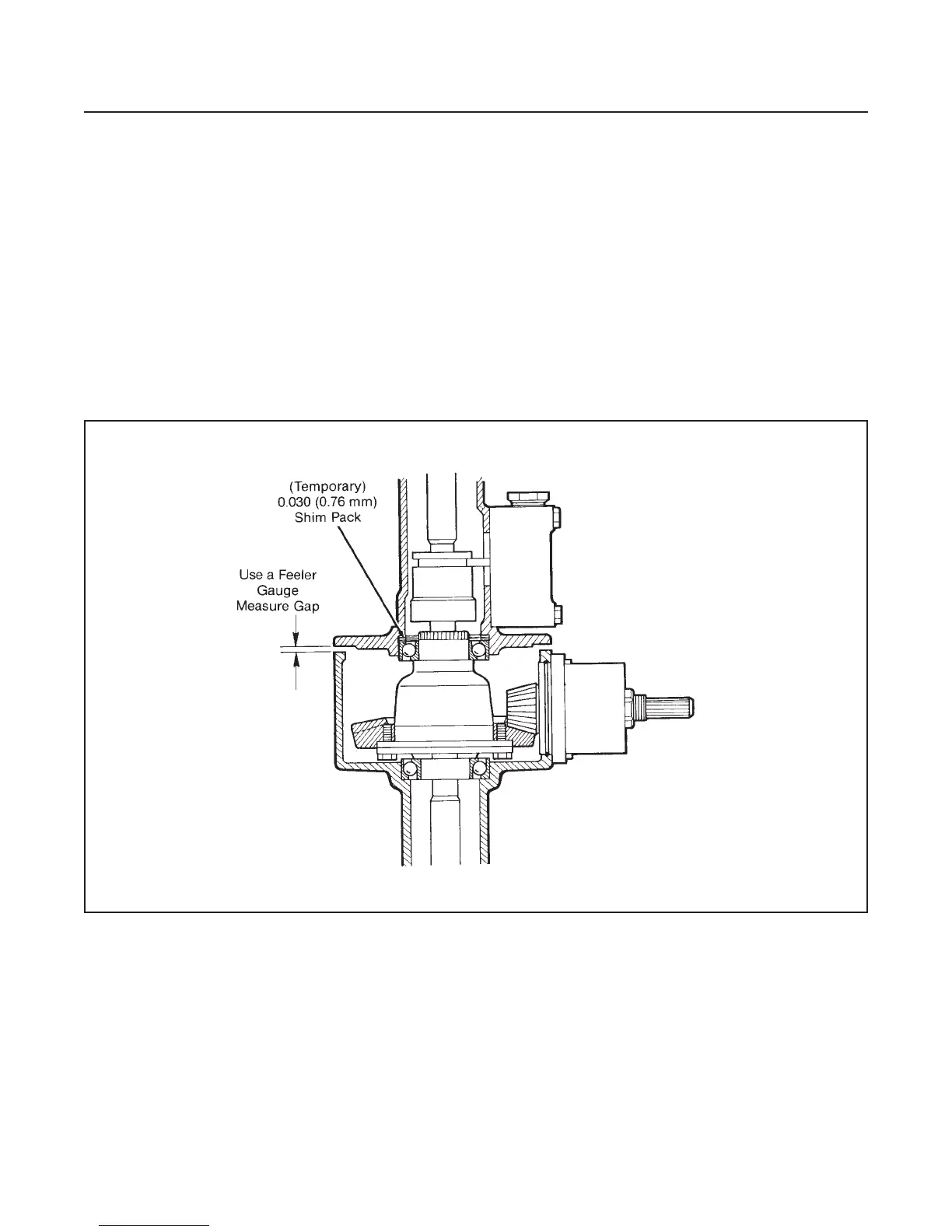

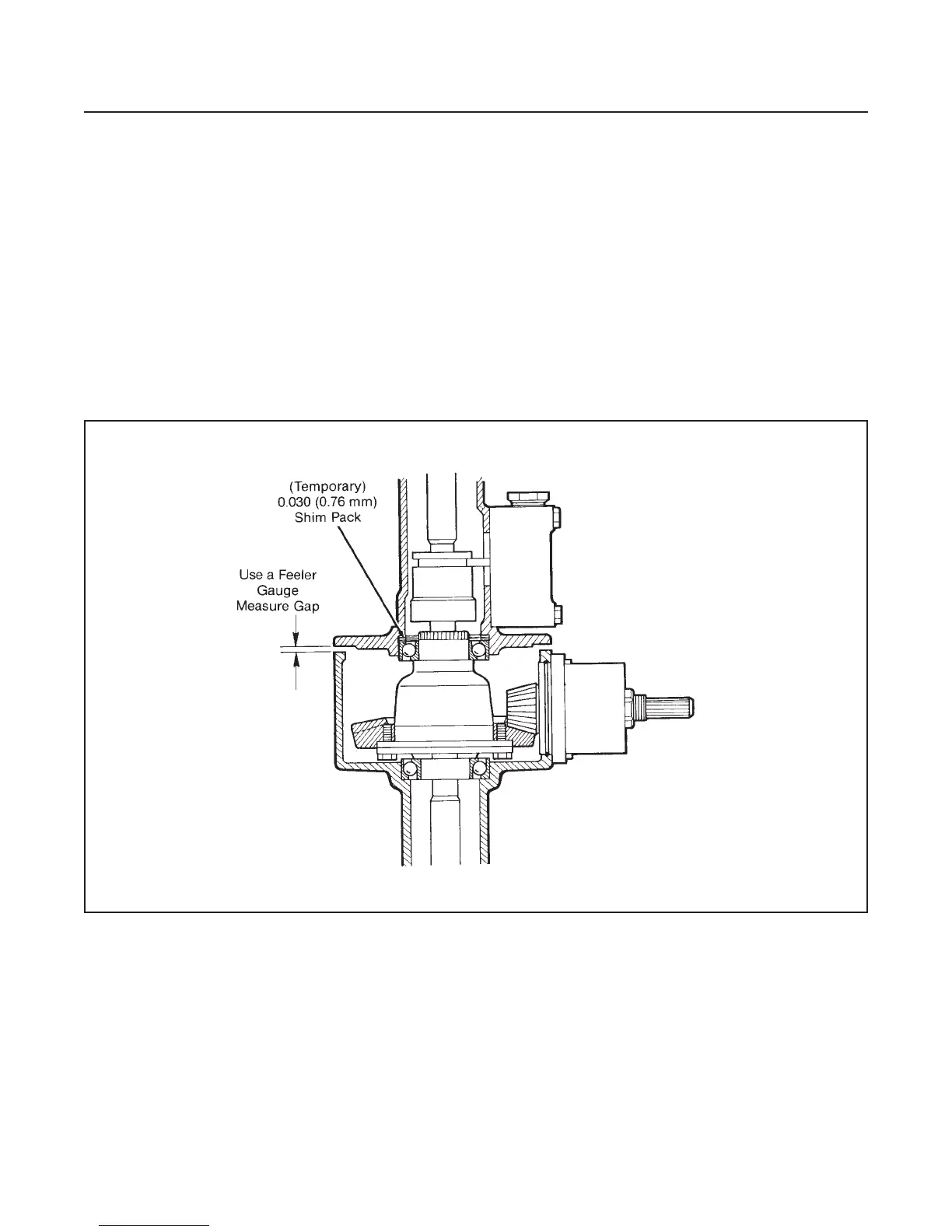

(See Figure 4E-13)

8. Build a shim pack equal to 0.030" (0.76 mm) and

install it in the bearing bore of the right axle.

9. Assemble both axle halves together.

10. Snug the bolts evenly, do not tighten.

11. Using a feeler gauge, measure the gap between

the two axle halves.

12. To this dimension subtract 0.004" (0.1 mm), then

subtract the total from the 0.030" (0.76 mm). This

is the thickness of the shim pack needed.

13. Separate the axle housing halves.

14. Replace the 0.030" (0.76 mm) shim pack with the

correct shim pack.

15. Continue to assemble axle as in Figure 4E-9.

DRIVE TRAIN

SECTION 4E. AXLE

4E-10

Figure 4E-13. Pinion and Ring Gear Backlash

Adjustment (Optional Method)

Loading...

Loading...