GENERAL

The hydrostatic transmission is driven by a telescop-

ing universal joint type drive shaft connected directly

between the hydro and engine flywheel plate.

REPAIR

Repairs are limited to renewing the cross and bearings.

SERVICE

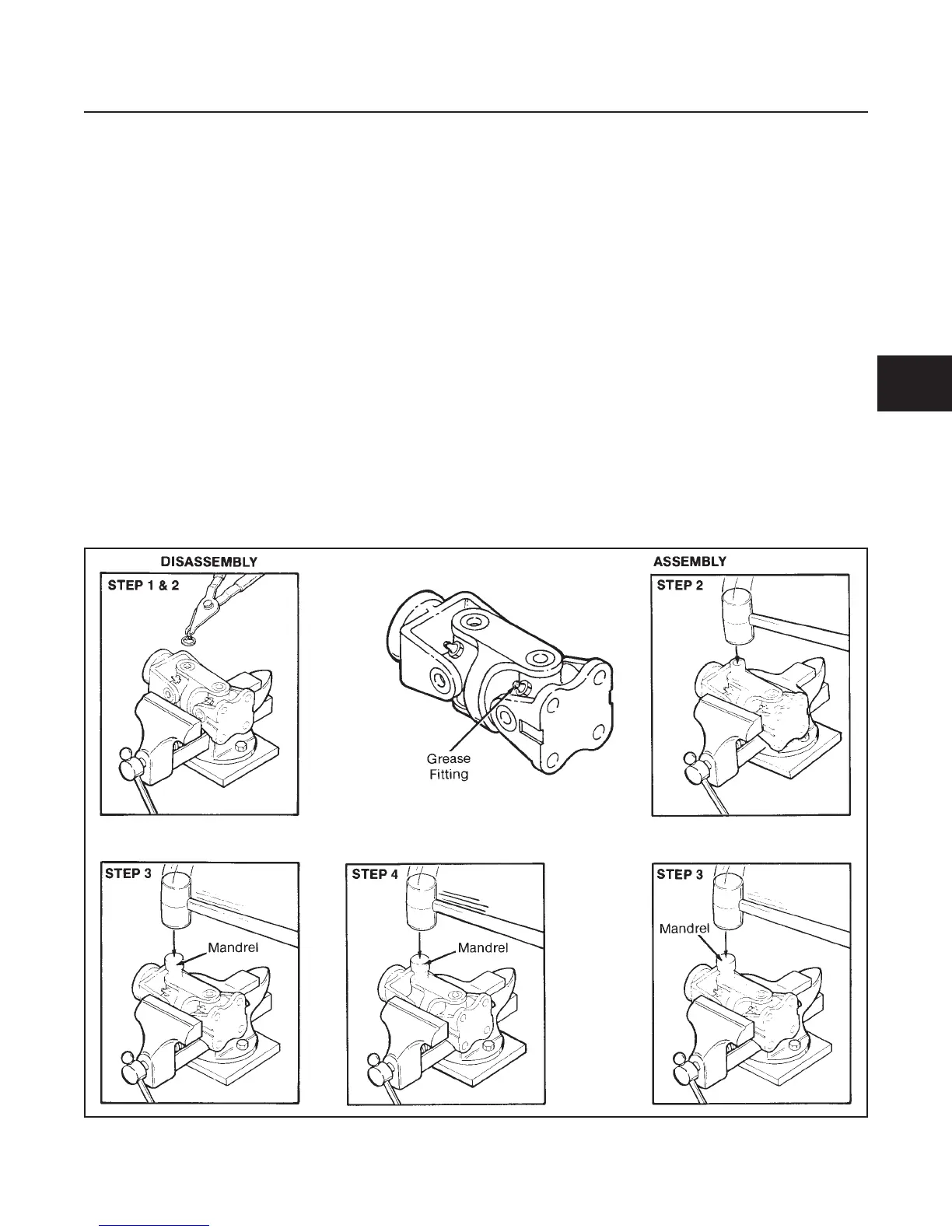

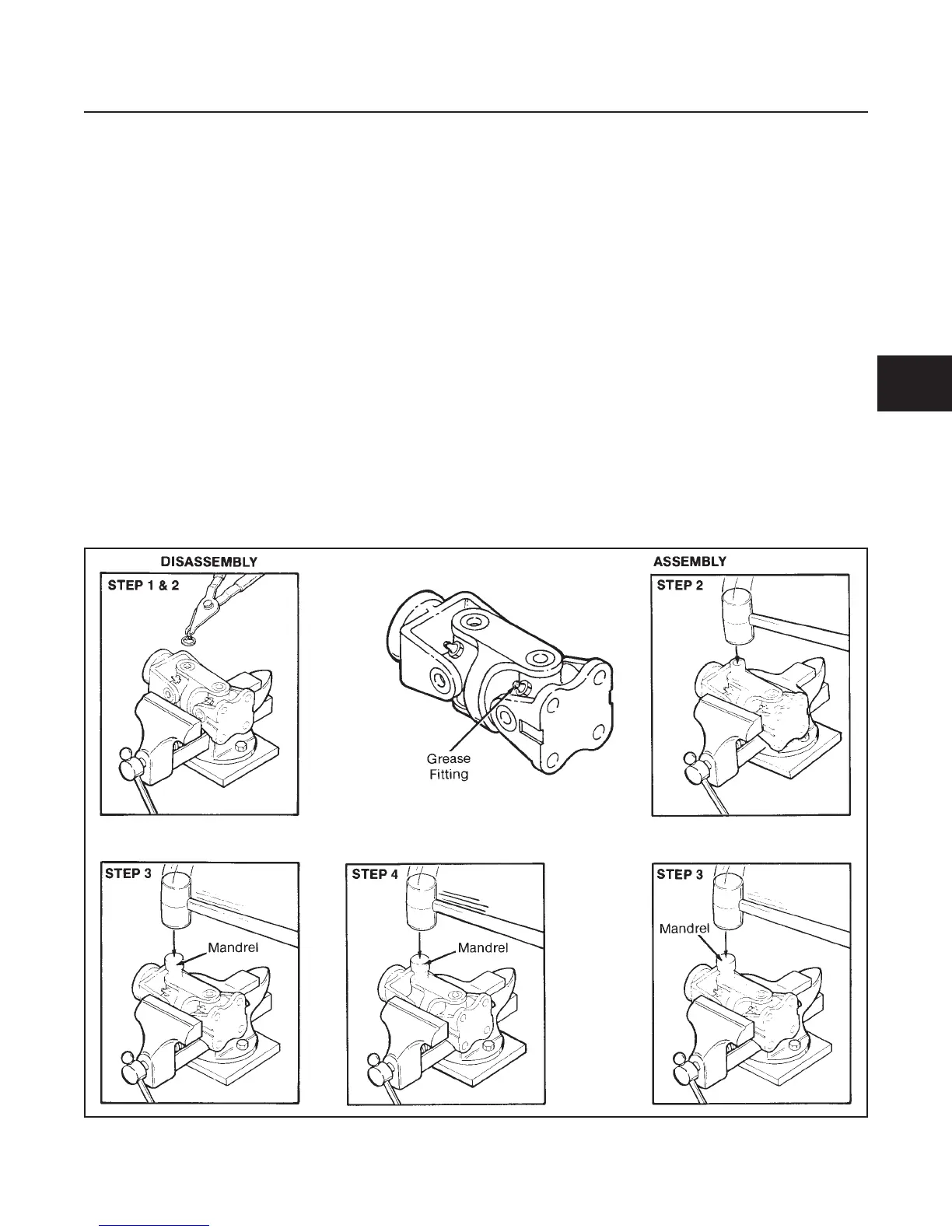

DISASSEMBLY (See Figure 4C-1)

1. Position the joint in a vise as shown.

2. Remove the four snap rings.

3. Using a driver slightly smaller than the outside diam-

eter of the bearing, drive the bearing in forcing the

bearing on the opposite side out.

4. Turn the drive shaft around and driving on the cross,

push opposite bearing out.

5. Repeat Steps 3 and 4 for the remaining bearings.

ASSEMBLY (See Figure 4C-1)

NOTE

During reassembly be sure all the parts are clean

and free of dirt.

1. Start one bearing in yoke ear and position center

cross through yoke.

2. Drive the first bearing flush with outside surface of

ear.

NOTE

Do not bend ear of yoke.

3. Support the ear and using a mandrel the same

diameter as the bearing, drive the bushing slightly

past the snap ring groove.

4. Install the snap ring.

5. Repeat Steps 3 and 4 for the other bearings.

6. After assembly, ensure proper seating by striking

the forged surfaces of the yoke ear one sharp blow

with a soft mallet.

7. Lubricate the joint as described in Section 11.

DRIVE TRAIN

SECTION 4C. HYDROSTAT DRIVE U-JOINT

4C-1

4C

Figure 4C-1. Drive Shaft

Loading...

Loading...