8. One at a time, loosen the high pressure fuel injec-

tor line nuts at the injector while cranking the

engine.

9. When bubbles disappear, tighten the fuel line nuts.

Repeat Steps 6 and 7 for the remaining fuel injec-

tion lines.

10. When all the lines have been purged and the

engine is running, listen to the engine. If it sounds

like it’s missing, repeat Steps 6 and 7 for all the

injection lines.

ENGINE REMOVAL

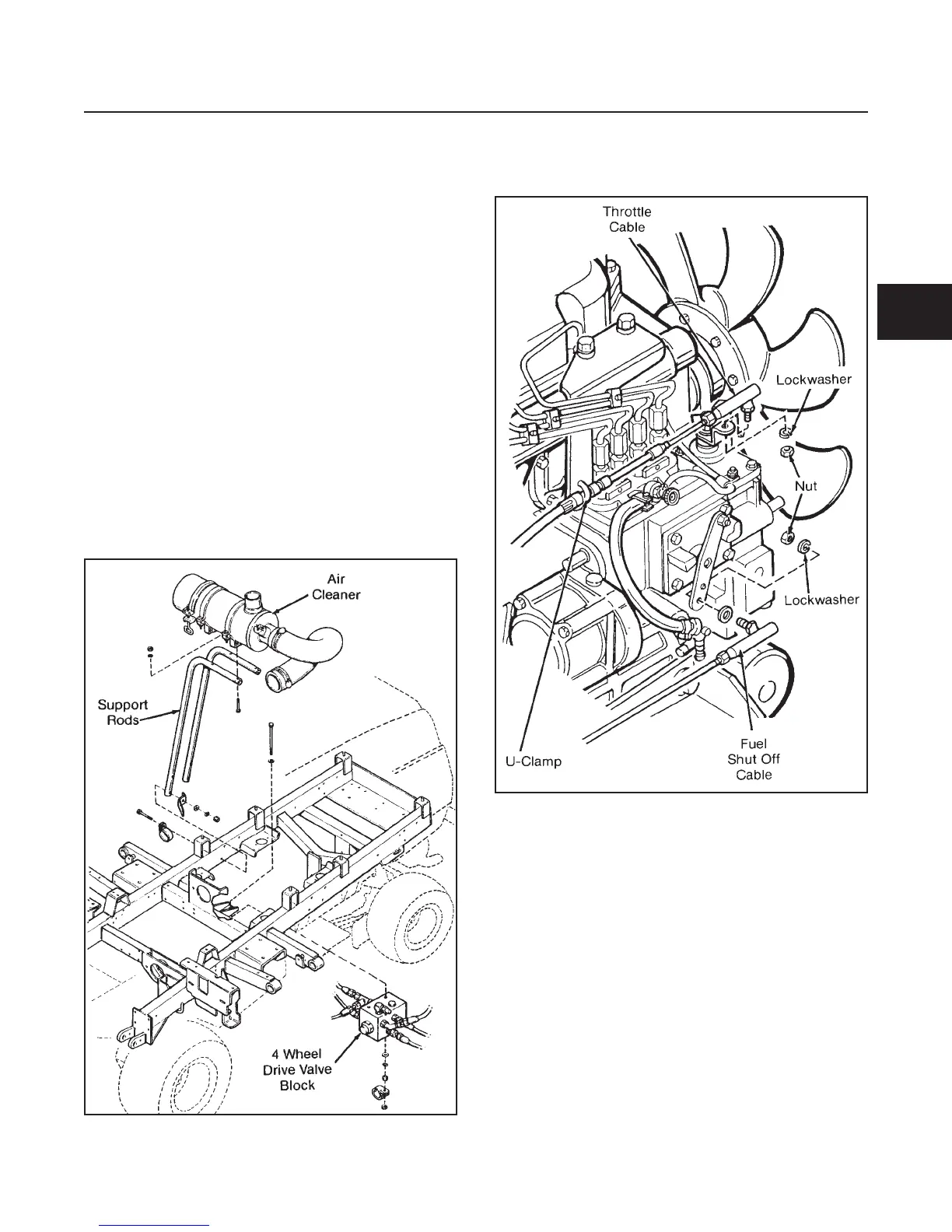

(See Figures 3D-6 to 3D-8)

1. Disconnect and tag all electrical connections at the

engine.

2. Remove the fuel line from engine.

3. Disconnect air cleaner and support rods (see Fig-

ure 3D-6).

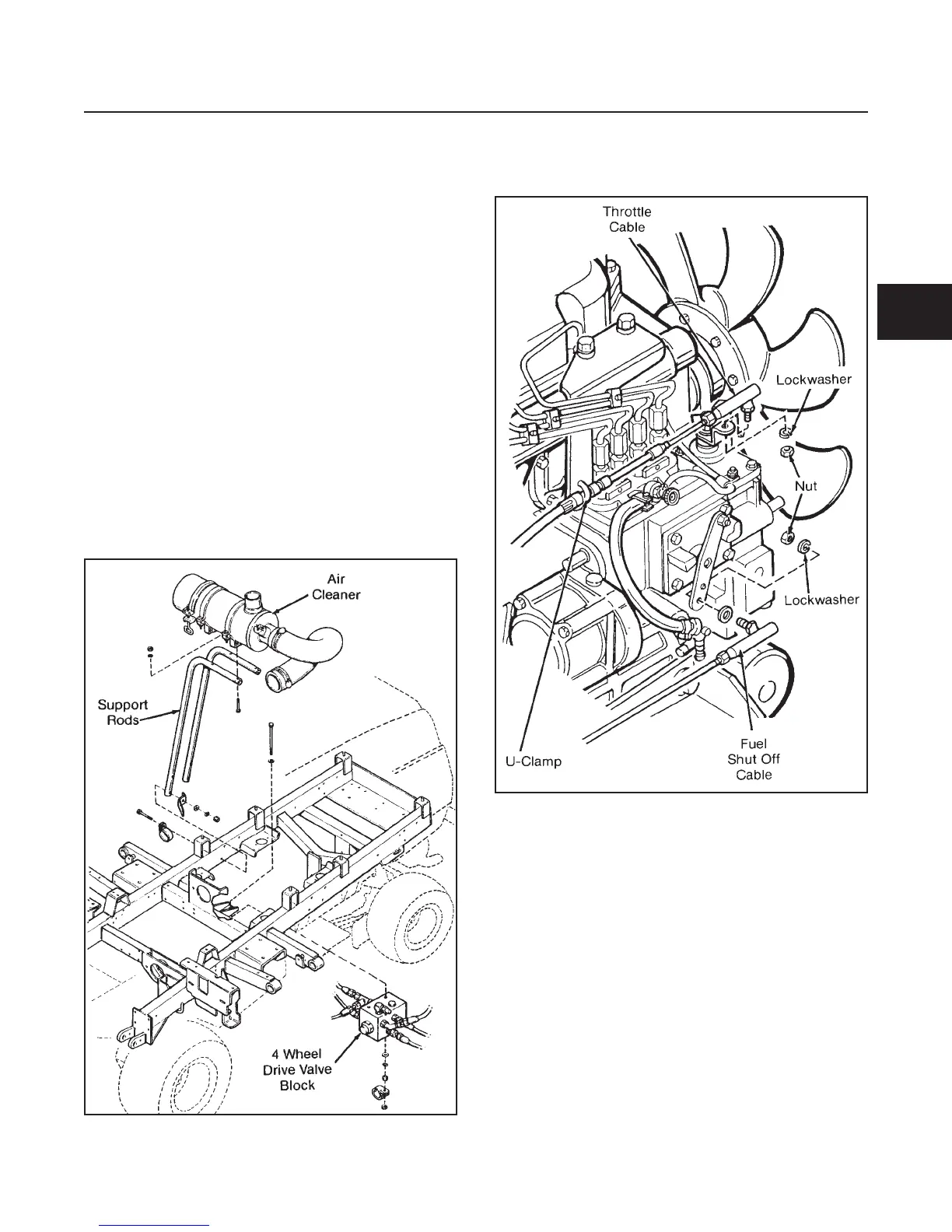

4. Disconnect the throttle cable at the fuel injection

pump (Figure 3D-7).

5. Remove the exhaust pipe and radiator shroud de-

scribed in preceding paragraphs (see Figure 3D-2

and 3D-3).

6. Tag and remove hydraulic lines from 4 wheel drive

valve block (see Figure 3D-6).

7. Remove 4 wheel drive valve block.

8. Remove the bolts (1) and lockwashers (2) that

mount the hydrostatic pump drive plate (3) to the

engine (see Figure 3D-8).

9. Attach a chain hoist to the engine (the engine

weighs approximately 400 lbs.).

10. Remove all bolts (4), lockwashers (5) and flat

washers (6) that hold the engine to the machine

frame.

11. Carefully lift the engine out of the machine.

ENGINE

SECTION 3D. DIESEL ENGINE

3D-5

3D

Figure 3D-6. Component Removal

Figure 3D-7. Fuel Shut-Off Solenoid and

Throttle Cable Connections

Loading...

Loading...