ATTACHMENTS

SECTION 12B. FAILURE ANALYSIS

12B-1

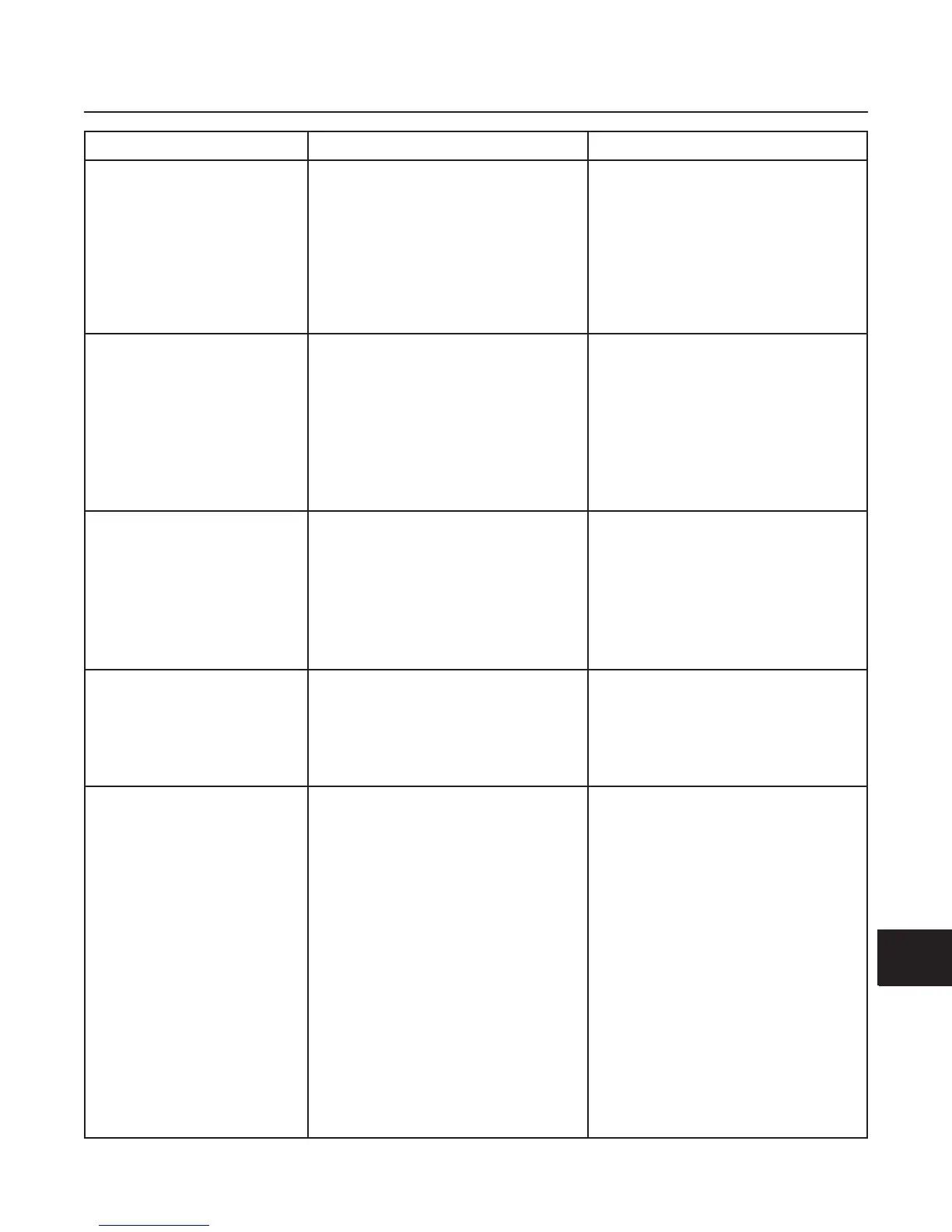

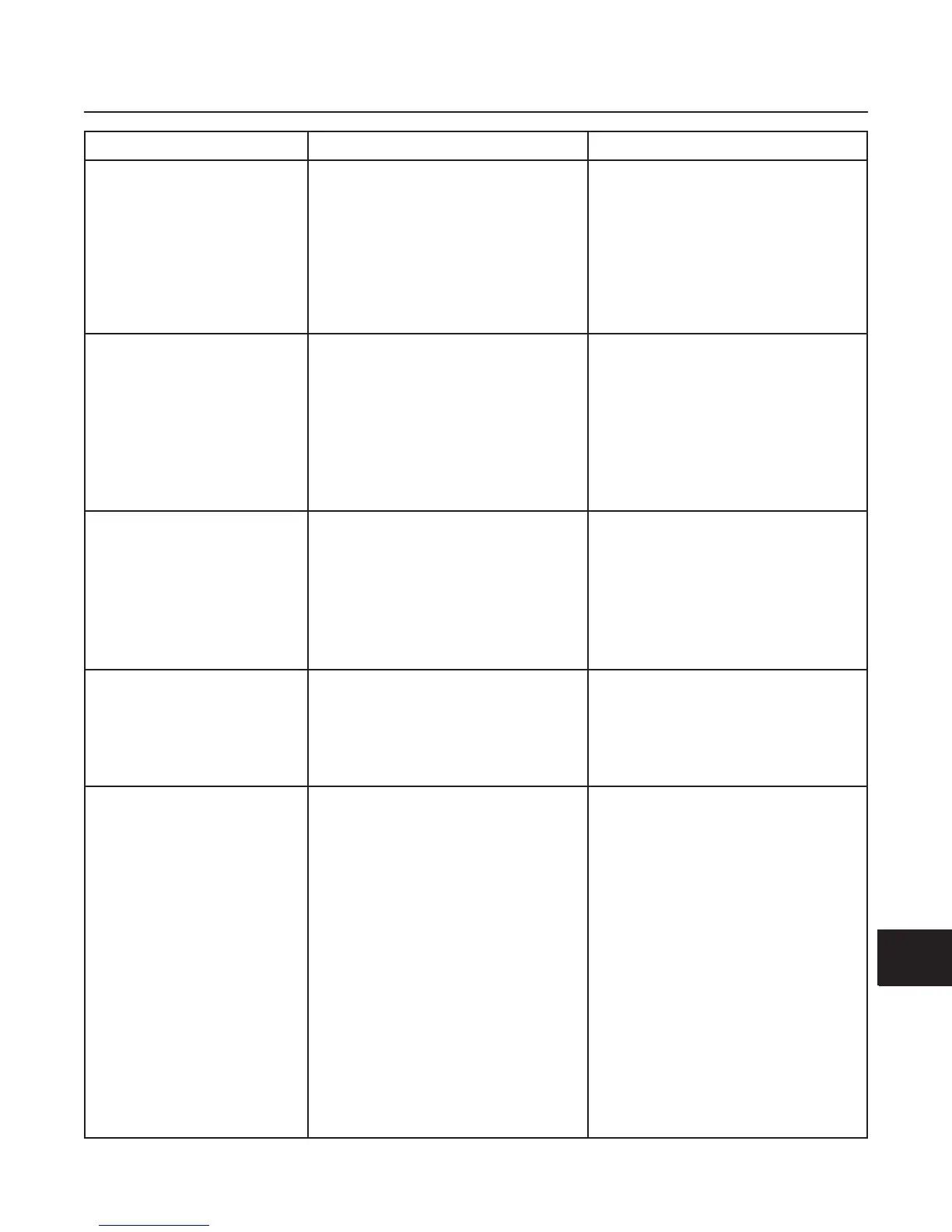

PROBLEM PROBABLE CAUSE REMEDY

1. Blades do not turn. a. Blades jammed. a. Clean underside of deck.

b. Spindle bearing failure. b. Check bearings, repair

(Section 12D).

c. Drive assembly malfunctioning. c. Inspect, repair (Section 12D).

d. Drive motor malfunctioning. d. Repair/replace (Sections 8L,

8M, 8N).

e. Tractor hydraulic system e. Test (Sections 8M, 8N).

malfunctioning.

2. Blades run slow. a. Blades jammed. a. Clean underside of deck.

b. Spindle bearing failure. b. Check bearings, repair

(Section 12D).

c. Drive assembly malfunctioning. c. Inspect, repair (Section 12D).

d. Drive motor malfunctioning. d. Repair/replace (Sections 8L,

8M, 8N).

e. Tractor hydraulic system e. Test (Sections 8M, 8N).

malfunctioning.

3. Uneven cutting. a. Deck not adjusted level. a. Adjust deck (see Operator’s

Manual).

b. Blades loose. b. Tighten (Section 12D).

c. Blades bent. c. Replace.

d. Spindle bearing failure. d. Check bearings, repair

(Section 12D).

e. Deck shell bent. e. Replace.

4. Ragged cut. a. Operating too fast for conditions. a. Slow down ground speed (see

Operator’s Manual).

b. Blade dull. b. Sharpen/replace (Section 12F).

c. Blades loose. c. Tighten (Section 12F).

d. Blades installed wrong. d. Install correctly (Section 12F).

5. Excessive vibration. a. Blade not balanced. a. Balance (Section 12F).

b. Blades loose. b. Tighten (Section 12F).

c. Blades bent. c. Replace.

d. Spindle bearing failure. d. Check bearing, repair

(Section 12D).

e. Spindle housing or deck shell e. Replace.

cracked.

12B

Loading...

Loading...