Electrical Safety Inspection D-1

Appendix D Electrical Safety

Inspection

The following electrical safety tests are recommended as part of a comprehensive

preventive maintenance program. They are a proven means of detecting abnormalities

that, if undetected, could prove dangerous to either the patient or the operator. Additional

tests may be required according to local regulations.

All tests can be performed using commercially available safety analyzer test equipment.

These procedures assume the use of a 601PROXL International Safety Analyzer or

equivalent safety analyzer. Other popular testers complying with IEC 60601-1 used in

Europe such as Fluke, Metron, or Gerb may require modifications to the procedure.

Follow the instructions of the analyzer manufacturer.

The electrical safety inspection should be periodically performed every two years.

The safety analyzer also proves to be an excellent troubleshooting tool to detect

abnormalities of line voltage and grounding, as well as total current loads.

D.1 Power Cord Plug

D.1.1 The Power Plug

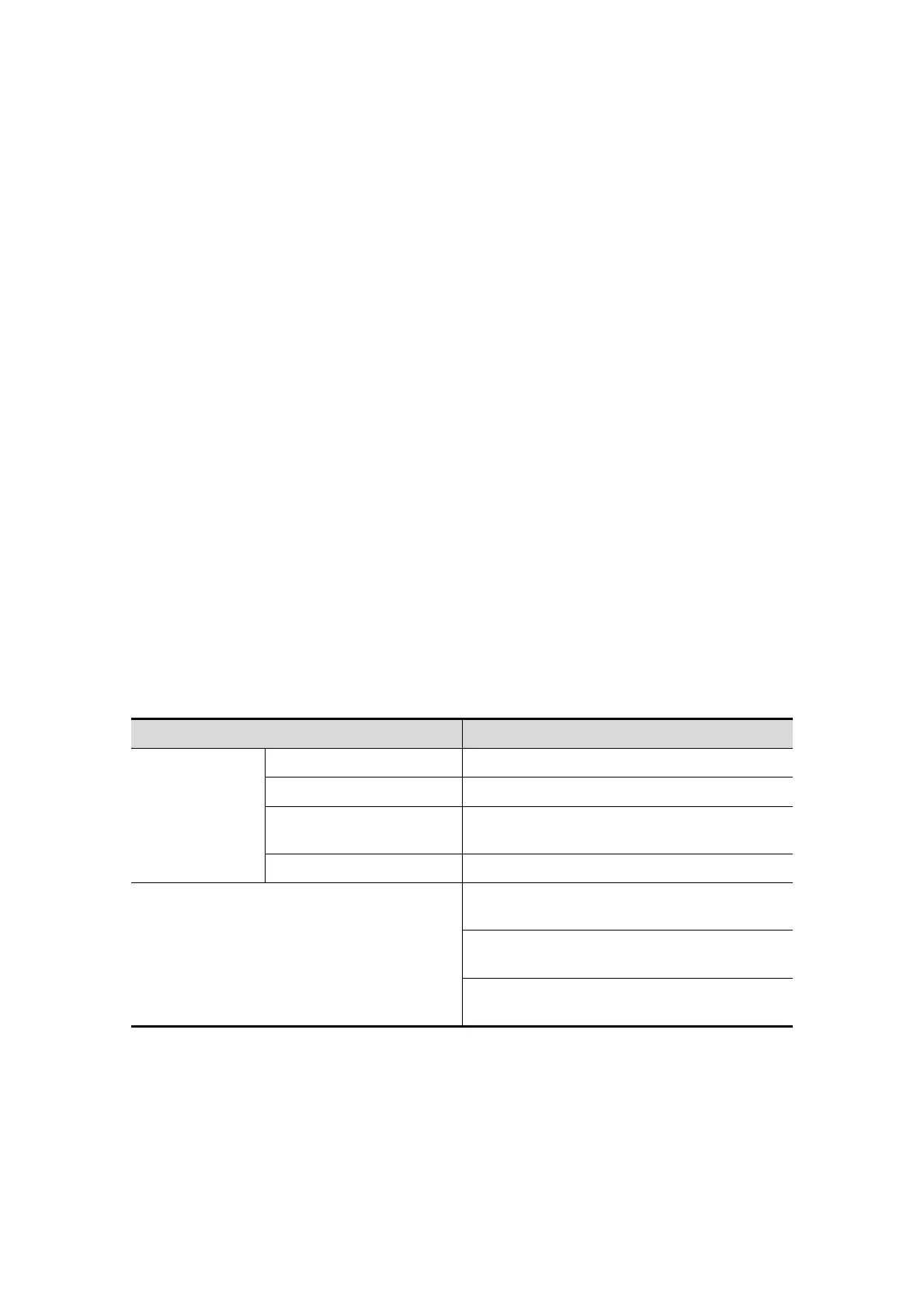

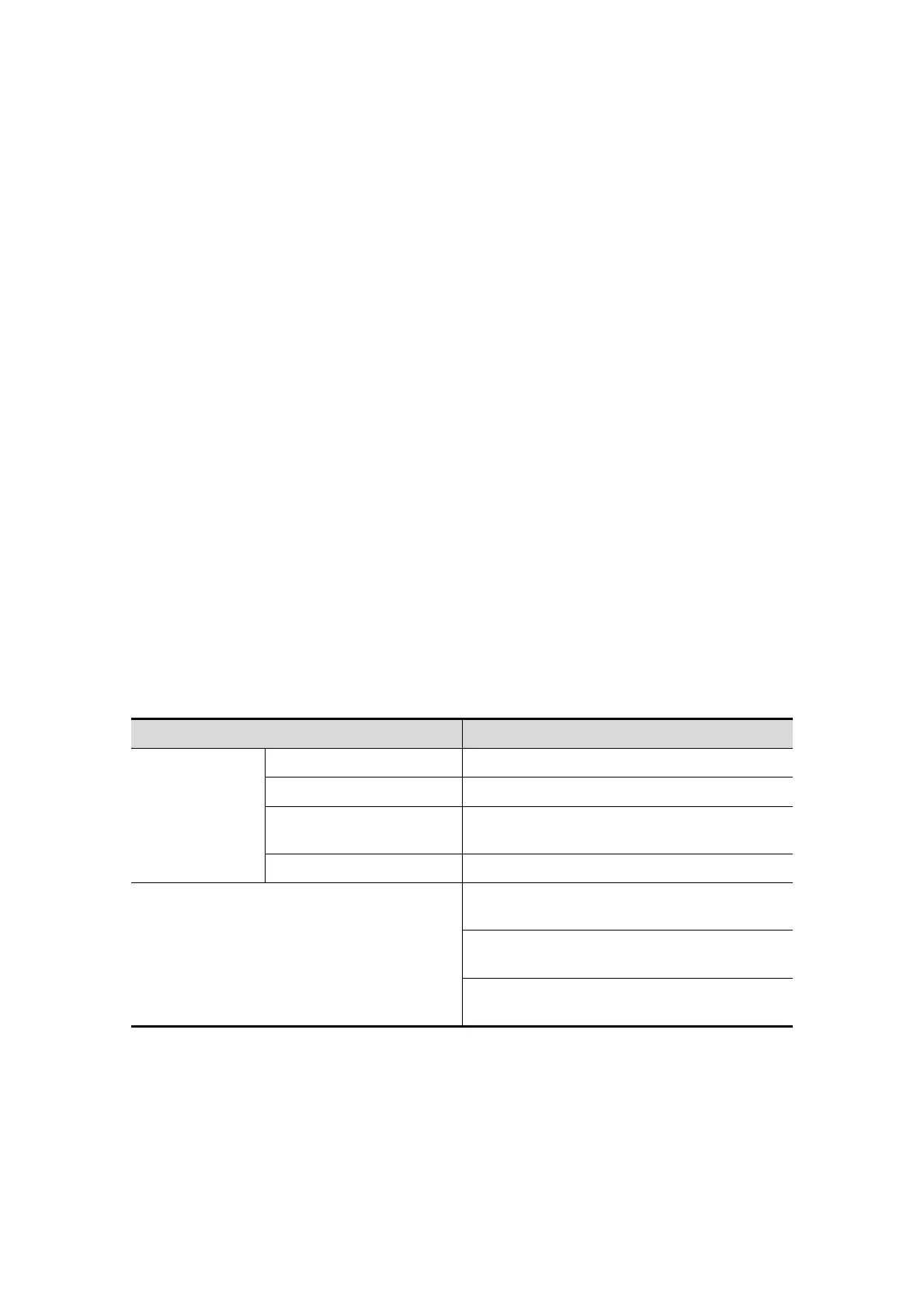

Test Item Acceptance Criteria

The power plug

The power plug pins No broken or bent pin. No discolored pins.

The plug body No physical damage to the plug body.

The strain relief

No physical damage to the strain relief. No

plug warmth for device in use.

The power plug No loose connections.

The power cord

No physical damage to the cord. No

deterioration to the cord.

For devices with detachable power cords,

inspect the connection at the device.

For devices with non-detachable power

cords, inspect the strain relief at the device.

Loading...

Loading...