133

Tab. Setup Screen

Item Explanation

Factory

preset value

(1) Maintenance Forecast is

made effective.

If this is checked, the Maintenance Forecast function takes effect.

*If a checkmark is removed, the collection of the information for

Maintenance Forecast stops, and the correct maintenance times cannot

be calculated.

Check ON

(2) Collection level of

information

Five levels can be specified to collect the information about the

maintenance.

*As an information collection level gets higher, the accuracy of the

maintenance improves, but it affects the tact time more.

1

(Recommend

ed)

(3) The interval of the

forecast

Specify the interval to notify the maintenance time. 6 hours

How to inform

When the grease replenishment, belt replacement and other maintenance times

have reached, they can be notified by generating a warning or outputting a dedicated

signal. As for the battery replacement time, one of warnings, C7500, C7510 and

C7520, is generated, regardless of whether or not [Warning] under [How to inform] is

checked. A warning to be generated varies depending on each situation.

(4) Warning If this item is checked, the maintenance time is notified as a warning. The

warning numbers are listed as follows:

Grease : C753* (* is the axis No.)

Belt : C754* (* is the axis No.)

Check ON

(5) Output Signal If this item is checked, signal numbers can be entered. If this item is

checked and a signal number is entered correctly, the maintenance time

is notified using the output of the designated signal.

Check OFF

(6) Assumption operation

time of a day

Enter an estimated robot operation hours per day. 16 hours

(7) The remainder days

until presumed

maintenance time

Specify the number of days remaining until presumed maintenance time

to be used as a reference to notify the maintenance time.

14 days

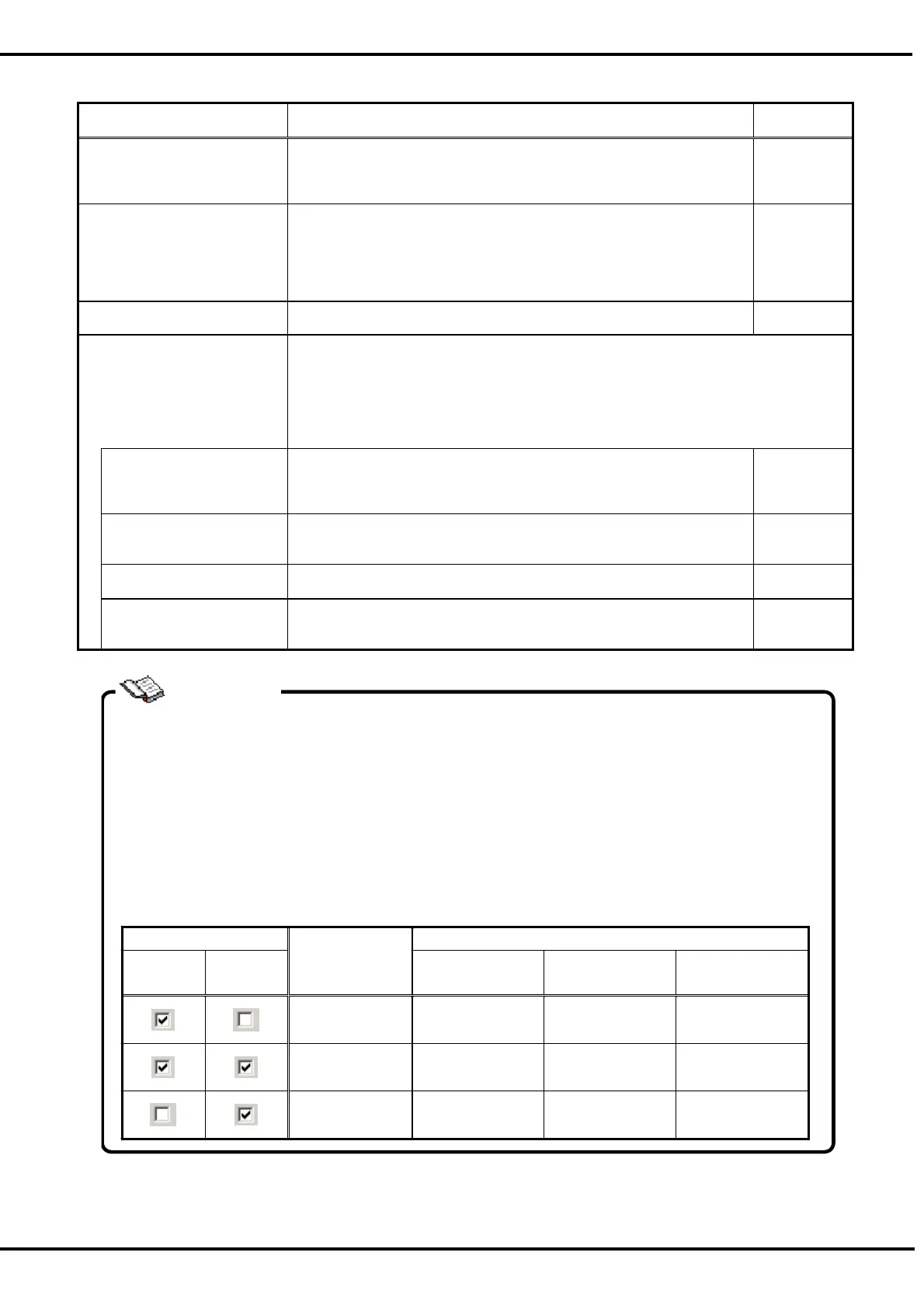

Methods for resetting the alarm and alarm signal output

As a method of notifying the replacement time of each part, an alarm (C753* and C754* (* represents

the axis number)), or a dedicated output signal (M*PTEXC (* represents the robot number)) will be

output.

If both are set up as the notification methods, executing the error reset operation will reset the alarm

and end the signal output.

If the “alarm” method is disabled and only the output of the dedicated output signal is selected as the

notification method, pushing the reset button on the front side of the controller will not end the signal

output. In this case, push the [RESET] key on the teaching pendant or enter the error reset signal

(ERRRESET) to end the signal output.

Notification method setting Methods to reset the notification (alarm or dedicated signal output)

Warning

Output

Signal

Notification method

[RESET] key on the

front of the controller

[ERROR RESET]

key on the T/B

External error reset

signal

Alarm

Will reset the alarm Will reset the alarm Will reset the alarm

Alarm and

dedicated signal

output

Will reset the alarm

and the dedicated

signal output

Will reset the alarm

and the dedicated

signal output

Will reset the alarm

and the dedicated

signal output

Dedicated signal

output

Will not reset the

dedicated signal

output

Will ENABLE reset

the dedicated signal

output

Will ENABLE reset

the dedicated signal

output

Memo

Loading...

Loading...