6-26

6-5 DC Injection Braking Function

The DC injection braking function applies DC on the induction motor for braking control.

Startup DC Injection Braking:

This braking is used for stopping and starting the motor rotating by inertia with no regen-

erative processing.

DC Injection Braking to Stop:

Adjust the stop DC injection braking time if the motor rotating does not decelerate to a

stop in normal operation due to inertia from a heavy load. By increasing the DC injection

braking time or DC injection braking current, the time required for stopping the motor is

reduced.

n089

DC Injection Braking Current Register 0159 Hex Changes during

operation

No

Setting

range

0 to 100 (%) Unit of

setting

1% Default setting 50

n090

DC Injection Braking-to-stop Time Register 015A Hex Changes during

operation

No

Setting

range

0.0 to 25.5 (s) Unit of

setting

0.1 s Default setting 0.5

n091

Startup DC Injection Braking Time Register 015B Hex Changes during

operation

No

Setting

range

0.0 to 25.5 (s) Unit of

setting

0.1 s Default setting 0.0

• Set the DC injection braking current as percentage based on the rated current of the Inverter as 100%.

• After the startup DC injection braking time is set, the Inverter starts up at minimum frequency on com-

pletion of the startup DC injection braking control of the Inverter.

• After the speed is reduced, the Inverter is switched to DC injection braking at minimum output fre-

quency.

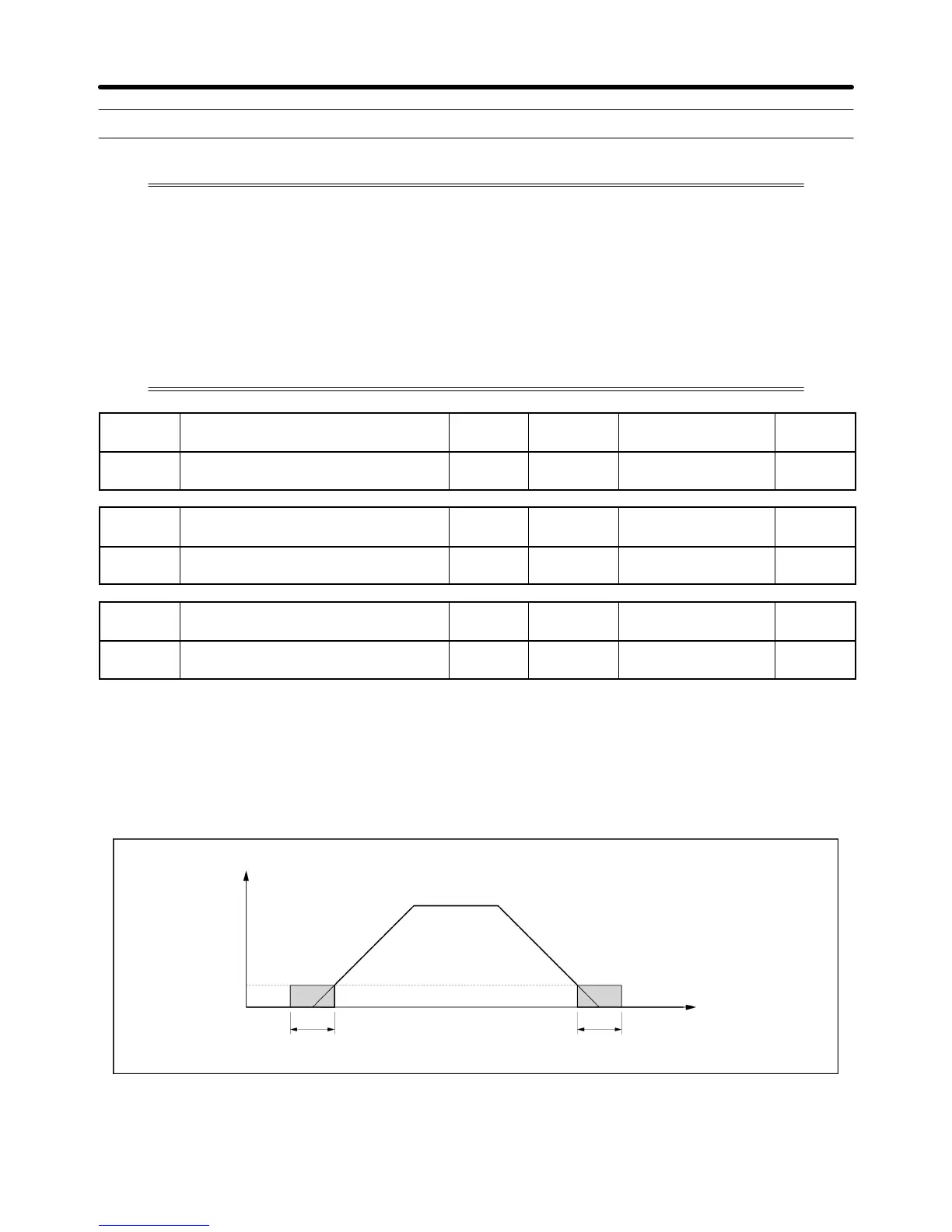

DC Injection Braking Control

Output

frequency

Minimum

output

frequency

(n016)

n091

Startup DC injection

braking time

n090

DC injection

braking-to-stop time

Time

Note It is normally not necessary to change the settings of n173 (Proportional Gain for DC Control) and

n174 (

Integral Time Constant for DC Control). Adjust n89 to n91 to achieve optimum performance.

Advanced Operation Chapter 6

Loading...

Loading...