2-35

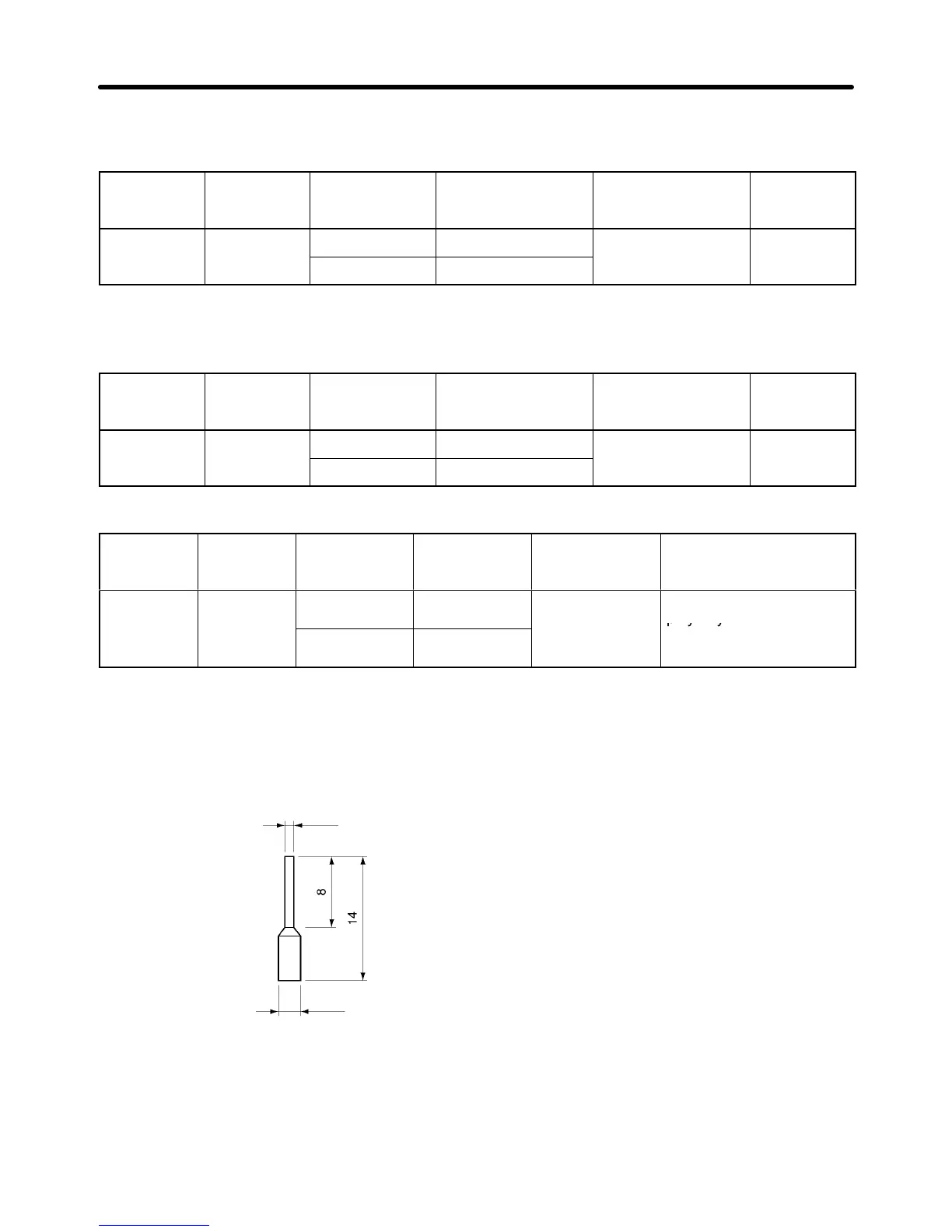

D Wires and Tightening Torque

Multi-function Contact Output (MA, MB, and MC)

Terminal

screw size

Tightening

torque

N S m

Wire Wire size mm

2

(AWG)

Recommended

wire size mm

2

(AWG)

Cable

M3 0.5 to 0.6

Single wire 0.5 to 1.25 (20 to 16)

0.75 (18) Cable with

Stranded wire 0.5 to 1.25 (20 to 16)

po

ye

y

ene

sheath

Sequential Input (S1 through S7 and SC), Multi-function Photocoupler Output (P1,

P2, PC), RS-422/485 Communications (R+, R–, S+, S–) and Multi-function Analog

Output (AM or AC), and Pulse Train Input (RP)

Terminal

screw size

Tightening

torque

N S m

Wire Wire size mm

2

(AWG)

Recommended

wire size mm

2

(AWG)

Cable

M2 0.22 to 0.25

Single wire 0.5 to 1.25 (20 to 16)

0.75 (18) Cable with

Stranded wire 0.5 to 0.75 (20 to 18)

po

ye

y

ene

sheath

Frequency Reference Input (FR, FS, and FC)

Terminal

screw size

Tightening

torque

N S m

Wire Wire size

mm

2

(AWG)

Recommended

wire size mm

2

(AWG)

Cable

M2 0.22 to 0.25

Single wire 0.5 to 1.25 (20

to 16)

0.75 (18) Special cable with

polyethylene sheath and

Stranded wire 0.5 to 0.75 (20

to 18)

shield for measurement

use

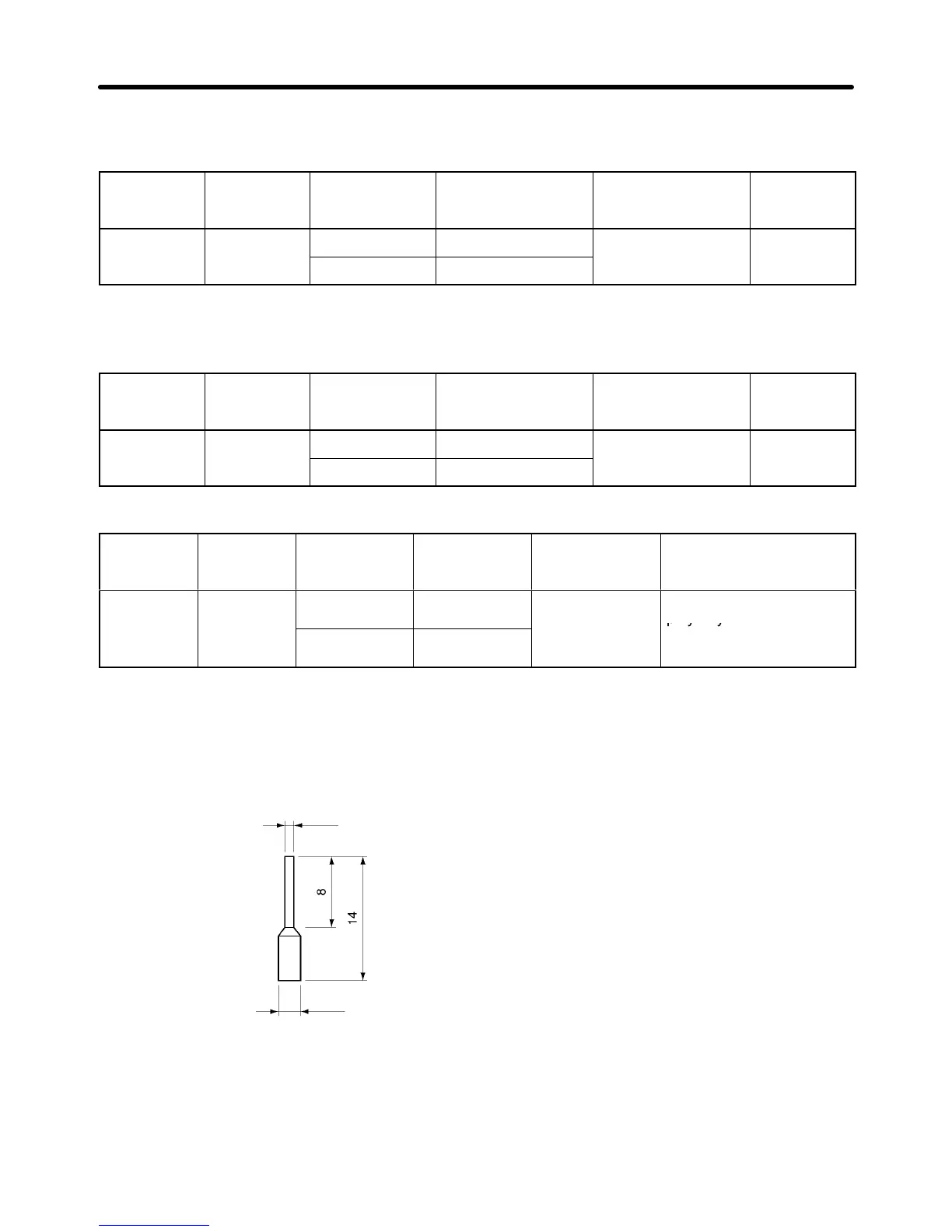

D Solderless Terminals for Control Circuit Terminals

The use of solderless terminals for the control circuit terminals is recommended because solderless

terminals are easy to connect securely.

Note When using the following solderless terminal, make sure that the wire size is 0.5 mm

2

.

1.0 dia.

2.6 dia.

Model: Phoenix Contact’s A1 0.5-8 WH

(Size: mm)

D Wiring Method

1. Loosen the terminal screws with a thin-slotted screwdriver.

2. Insert the wires from underneath the terminal block

3. Tighten the terminal screws firmly to a torque of 0.5 NSm.

Design Chapter 2

Loading...

Loading...