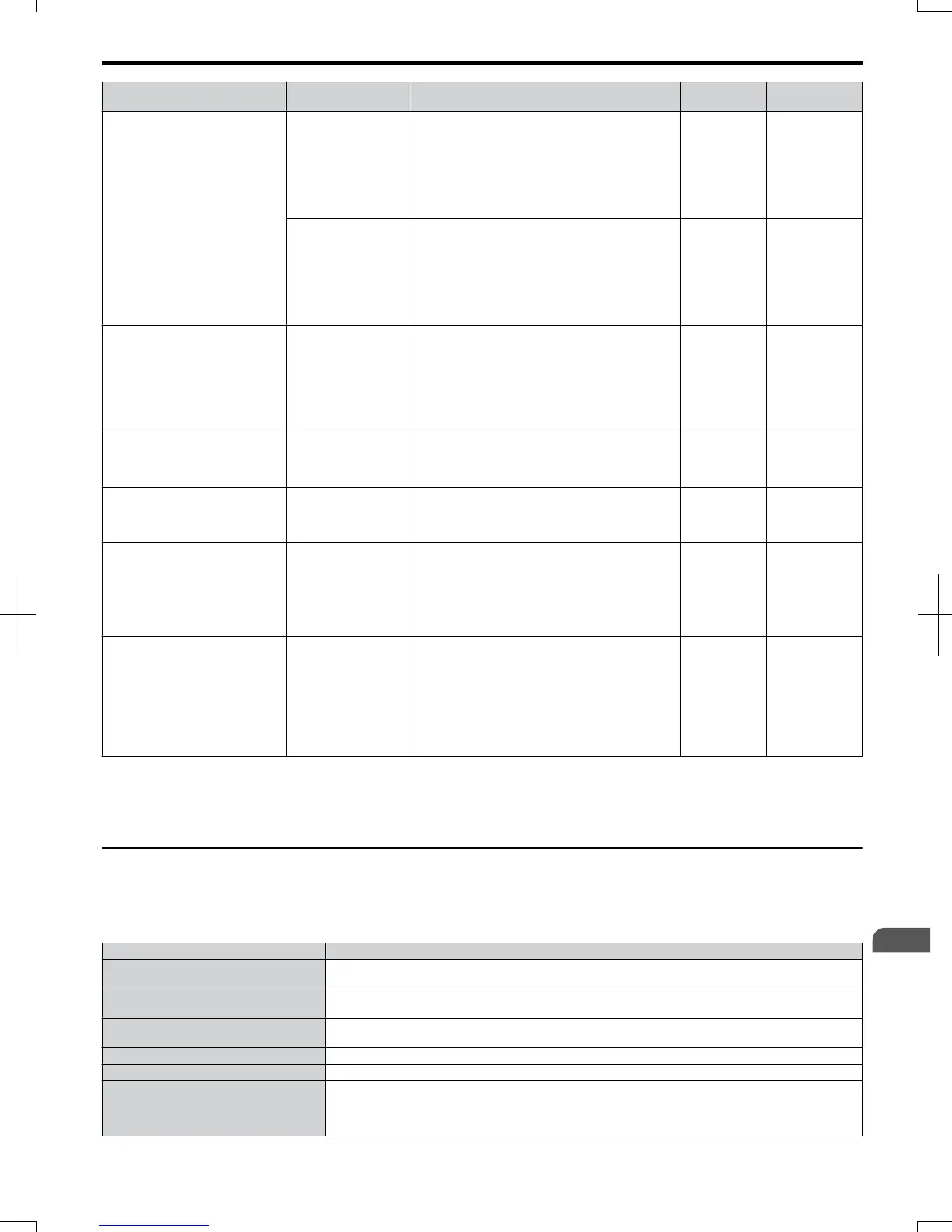

Problem Parameter No. Corrective Action Default Value

Suggested

Setting

• Overvoltage trips when

accelerating, decelerating, or

during sudden speed or load

changes.

AFR Time Constant 2

(n2-03)

• If overvoltage trips occur, gradually increase this

setting by 50 ms.

• If response is slow, gradually reduce this setting

by 10 ms.

Note: Ensure that n2-02 ≤ n2-03. When making

adjustments to n2-03, increase the value of C4-06

(Torque Compensation Primary Delay Time 2)

proportionally.

750 ms 750 to 2000 ms

Torque Compensation

Primary Delay Time

Constant 2 (C4-06)

• If overvoltage trips occur, gradually increase this

setting by 10 ms and check the performance.

• If response is slow, gradually reduce this setting

by 2 ms and check the performance.

Note: Ensure that C4-02 ≤ C4-06. When changing

C4-06 (Torque Compensation Primary Delay Time

Constant 2), increase the value of n2-03

proportionally.

150 ms 150 to 750 ms

• Poor motor torque and speed

response

• Motor hunting and oscillation.

Torque Compensation

Primary Delay Time

Constant 1

(C4-02)

• To improve motor torque speed response,

gradually reduce this setting by 2 ms and check

the performance.

• If motor hunting and oscillation occur, gradually

increase this setting by 10 ms.

Note: Ensure that C4-02 ≤ C4-06. When making

adjustments to C4-02, increase n2-02 (AFR Time

Constant) proportionally.

20 ms

<1>

20 to 100 ms

• Poor speed response and stability

Slip Compensation

Primary Delay Time

Constant (C3-02)

• If response is slow, gradually decrease the setting

by 10 ms.

• If speed is unstable, gradually increase the setting

by 10 ms.

200 ms

<1>

100 to 500 ms

• Poor speed precision

Slip Compensation

Gain (C3-01)

• If speed is too slow, gradually increase the setting

by 0.1 ms.

• If speed is too fast, gradually decrease the setting

by 0.1 ms.

1.0

<1>

0.5 to 1.5

• Motor noise

• Control motor hunting and

oscillation occur at speeds below

10 Hz.

Carrier Frequency

Selection (C6-02)

• If there is too much motor noise, the carrier

frequency is too high.

• If motor hunting and oscillation occur at low

speeds, reduce the carrier frequency.

• The default setting for the carrier frequency

depends on the drive capacity (o2-04) and Drive

Duty Selection (C6-01).

Dep. on drive

capacity

0 to the default

setting

• Poor motor torque at low speeds

• Poor speed response

• Motor instability at motor start.

Mid Output Voltage A

(E1-08)

Minimum Output

Voltage (E1-10)

• If motor torque and speed response are too slow,

increase the setting.

• If the motor exhibits excessive instability at start-

up, reduce the setting.

Note: The default value is for 200 V class units.

Double this value when using a 400 V class drive.

When working with a relatively light load,

increasing this value too much can create an

excessively high of a torque reference.

E1-08: 12.0 V

<1>

E1-10: 2.5 V

<1>

Initial ±2 V

<1> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03. The default

setting shown is for V/f Control.

When using OLV Motor Control, leave the torque compensation gain (C4-01) at its default setting of 1.00. To increase

speed precision during regeneration in OLV Motor Control, enable slip compensation during regeneration (C3-04 = “1”).

u

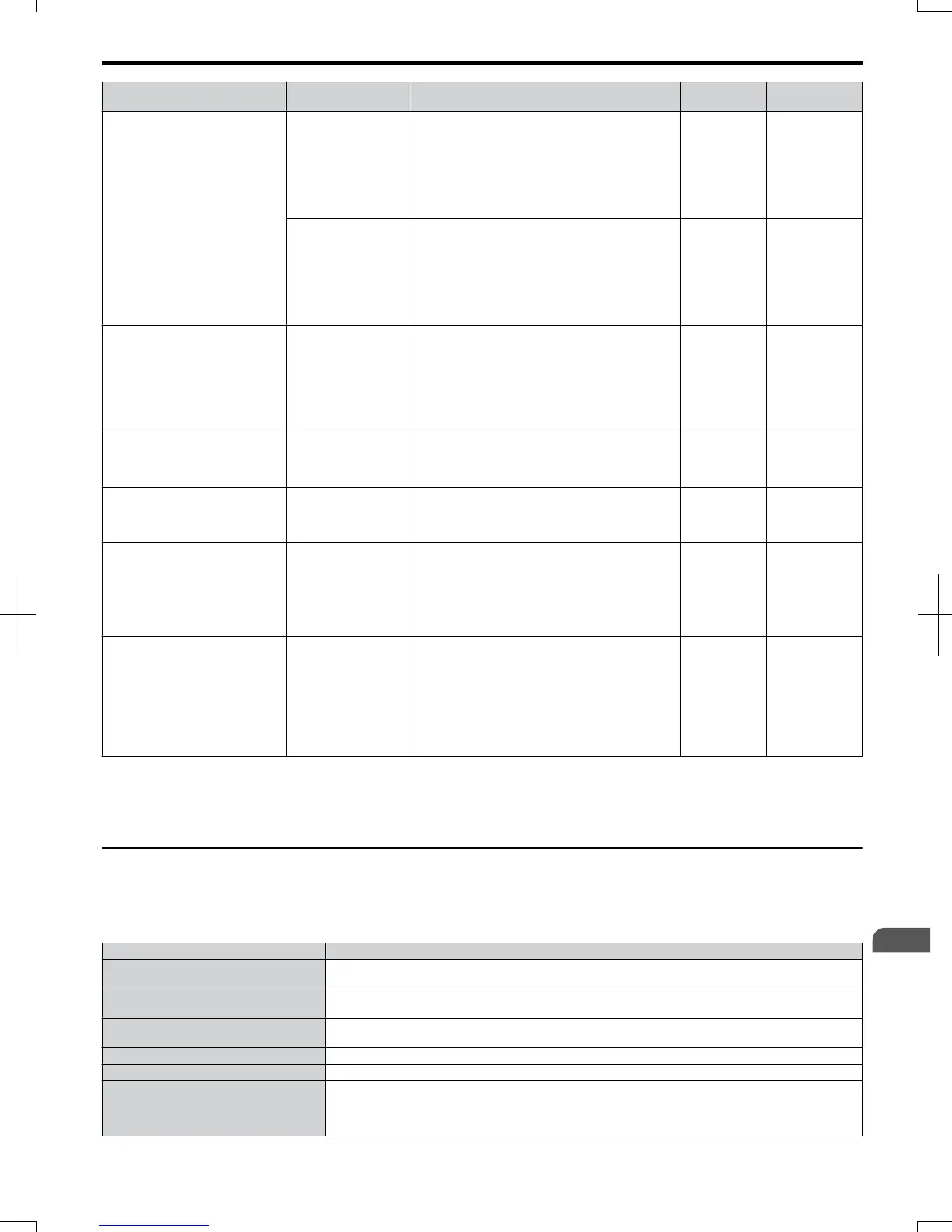

Motor Hunting and Oscillation Control Parameters

In addition to the parameters discussed on page 144, the following parameters indirectly affect motor hunting and

oscillation.

Table 6.3 Parameters that Affect Control Performance in Applications

Name (Parameter No.) Application

Dwell Function (b6-01 through b6-04)

Prevents motor speed loss by maintaining the output frequency when working with heavy loads or when

there is powerful backlash on the machine side.

Accel/Decel Time (C1-01 through

C1-09)

Adjusting accel and decel times will affect the torque presented to the motor during acceleration or

deceleration.

S-Curve Characteristics (C2-01 through

C2-04)

Prevents shock at the beginning and end of acceleration and deceleration.

Jump Frequency (d3-01 through d3-04) Skips over the resonant frequencies of connected machinery.

Analog Filter Time Constant (H3-13) Prevents fluctuation in the analog input signal due to noise.

Stall Prevention (L3-01 through L3-06,

L3-11)

• Prevents motor speed loss and overvoltage. Used when the load is too heavy and also during sudden

acceleration/deceleration.

• Adjustment is not normally required because Stall Prevention is enabled as a default. Disable Stall

Prevention during deceleration (L3-04 = “0”) when using a braking resistor.

6.2 Motor Performance Fine Tuning

SIEP C710606 20 OYMC AC Drive - V1000 User Manual

225

6

Troubleshooting

7/16/2008-13:23

Loading...

Loading...