6.9 Troubleshooting without Fault Display

This section describes troubleshooting problems that do not trip an alarm or fault.

u

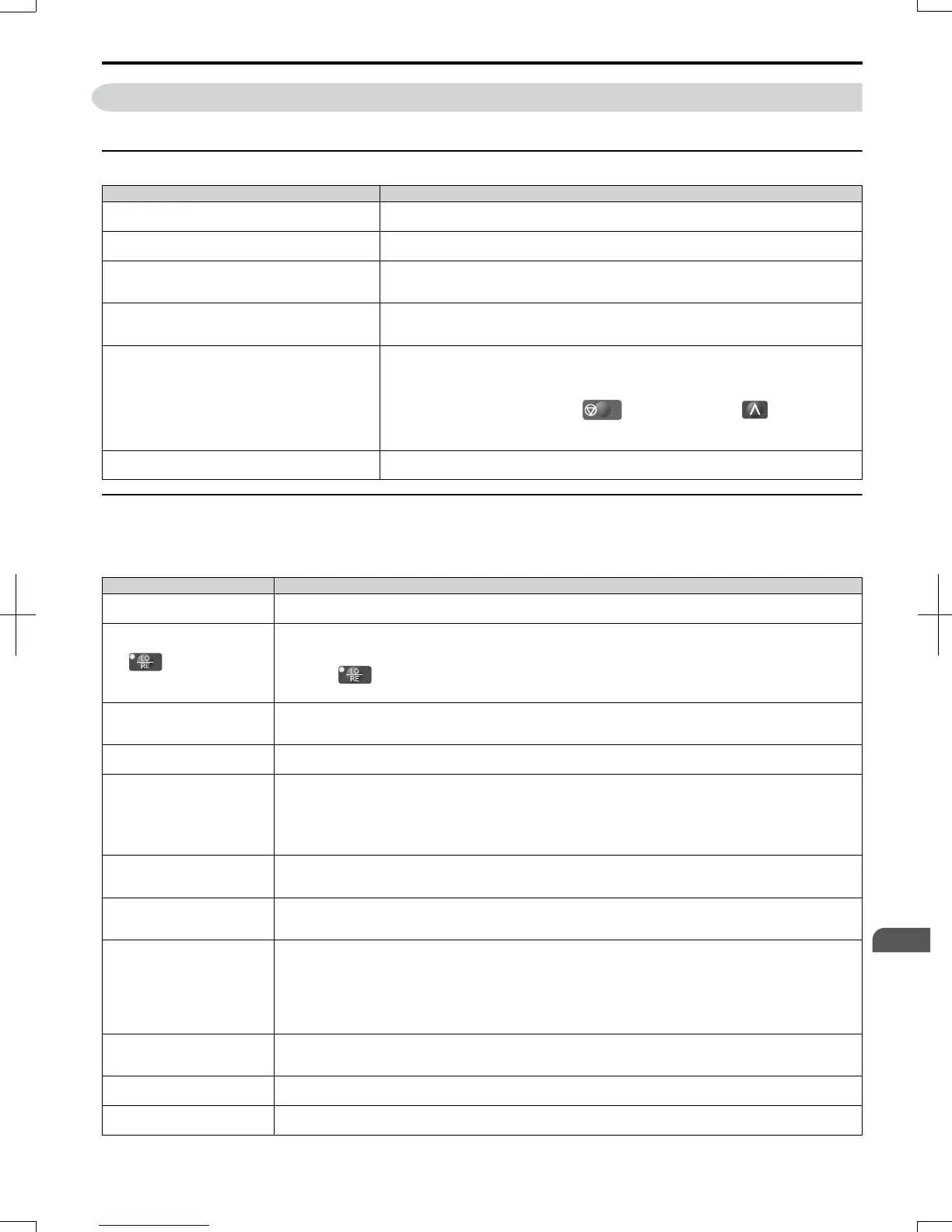

Cannot Change Parameter Settings

Cause Possible Solutions

The drive is running the motor (i.e., the Run command

is present).

• Stop the drive and switch over to the Programming Mode.

• Most parameters cannot be edited during run.

The Access Level is set to restrict access to parameter

settings.

• Set the Access Level to allow parameters to be edited (A1-01 = 2).

The operator is not in the Parameter Setup Mode (the

LED screen will display “PAr”).

• See what mode the LED parameter is current set for.

• Parameters cannot be edited when in the Setup Mode (“STUP”). Switch modes so that “PAr”

appears on the screen.

A multi-function contact input terminal is set to allow

or restrict parameter editing (H1-01 through H1-06 =

1B).

• When the terminal is open, parameters cannot be edited.

• Turn on the multi-function contact input set to 1B.

The wrong password was entered.

• If the password entered to A1-04 does not match the password saved to A1-05, then drive

settings cannot be changed.

• Reset the password.

If you cannot remember the password:

•

Display parameter A1-04. Press the

STOP

button while pressing at the same time.

Parameter A1-05 will appear.

• Set a new password to parameter A1-05.

Undervoltage was detected.

• Check the drive input power voltage by looking at the DC bus voltage (U1-07).

• Check all main circuit wiring.

u

Motor Does Not Rotate Properly after Pressing RUN Button or after Entering External

Run Command

n

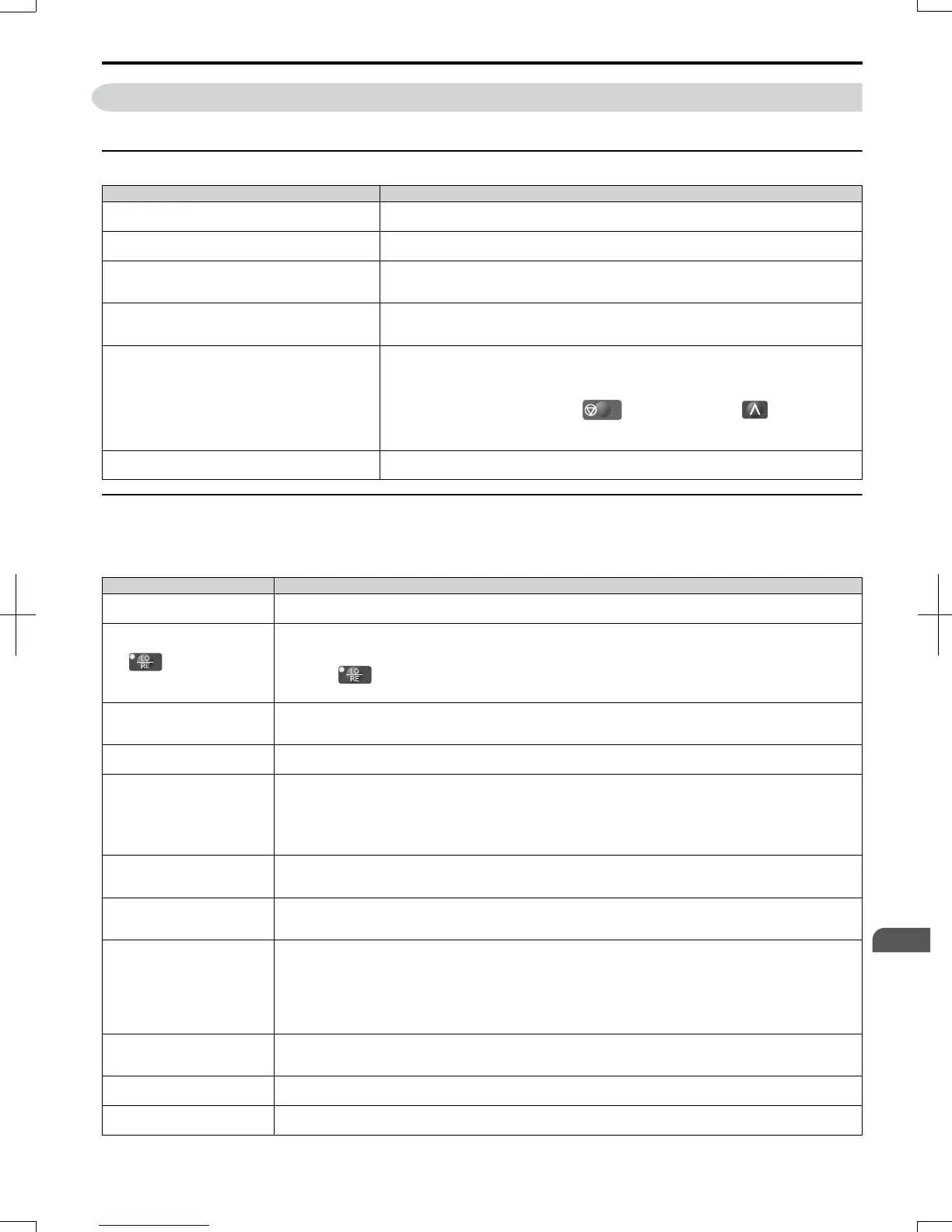

Motor Does Not Rotate

Cause Possible Solutions

The drive is not in the Drive

Mode.

• Check if the DRV light on the LED operator is lit.

• Enter the Drive Mode to begin operating the motor. Refer to The Drive and Programming Modes on page 70.

The button was pushed.

Stop the drive and check if the correct frequency reference source is selected. If the operator keypad shall be the

source, the LO/RE button LED must be on, if the source is REMOTE, it must be off.

Take the following steps to solve the problem:

•

Push the button.

• If o2-01 is set to 0, then the LO/RE button will be disabled.

Auto-Tuning has just completed.

• When Auto-Tuning has completed, the drive is switched back to the Programming Mode. The Run command

will not be accepted unless the drive is in the Drive Mode.

• Use the LED operator to enter the Drive Mode. Refer to The Drive and Programming Modes on page 70.

A Fast-Stop was executed and

has not yet been reset.

Reset the Fast-Stop command.

Settings are incorrect for the

source that provides the run

command.

Check parameter b1-02 (Run Command Selection).

Set b1-02 so that it corresponds with the correct run command source.

0: LED/LCD operator

1: Control circuit terminal (default setting)

2: MEMOBUS/Modbus communications

3: Option card

One of the Safety Inputs is open.

• Check for a short-circuit between terminals H1 and HC.

• See if one of the Safety Inputs is open.

• Correct any faulty wiring.

There is faulty wiring in the

control circuit terminals.

• Check the wiring for the control terminal.

• Correct wiring mistakes.

• Check the input terminal status monitor (U1-10).

The drive has been set to accept

the frequency reference from the

incorrect source.

Check parameter b1-01 (Frequency Reference Selection 1).

Set b1-01 to the correct source of the frequency reference.

0: LED operator

1: Control circuit terminal (default setting)

2: MEMOBUS/Modbus communications

3: Option card

4: Pulse train input (RP)

The terminal set to accept the

main speed reference is set to the

incorrect voltage and/or current.

If the frequency reference is set at terminal A1, check parameter H3-01 for the correct signal level selection. If

terminal A2 is used, check DIP switch S1. Then select the correct input level for terminal A2 in parameter H3-08.

Refer to DIP Switch S1 Analog Input Signal Selection on page 57.

Selection for the sink/source

mode is incorrect.

Check DIP switch S3. Refer to Sinking/Sourcing Mode Switch on page 55.

Frequency reference is too low.

• Check the frequency reference monitor (U1-01).

• Increase the frequency by changing the maximum output frequency (E1-09).

6.9 Troubleshooting without Fault Display

SIEP C710606 20 OYMC AC Drive - V1000 User Manual

253

6

Troubleshooting

7/16/2008-13:23

Loading...

Loading...