Wiring

Operating Manual PMCprotego D.48, PMCprotego D.72

1001735-EN-04

104

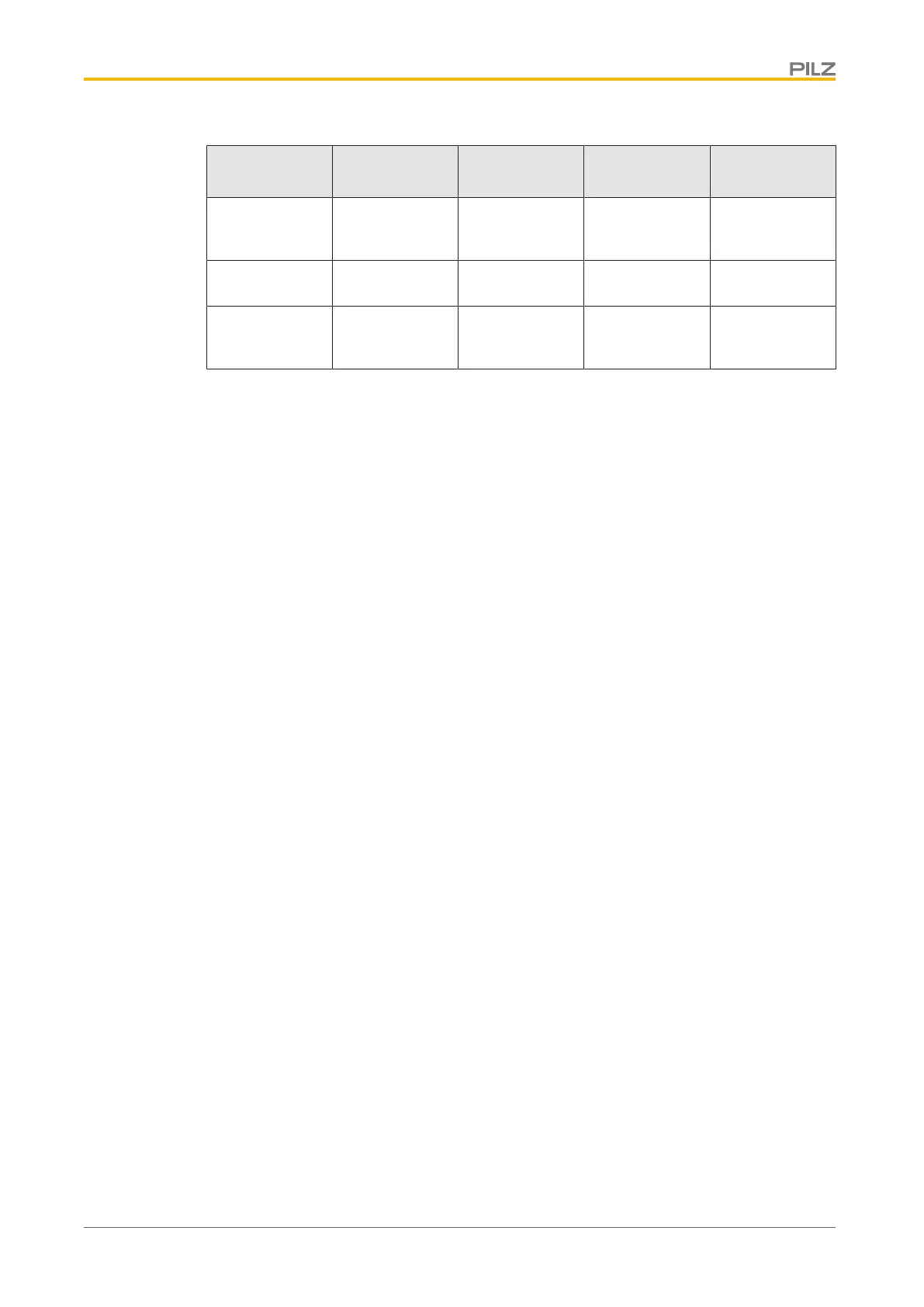

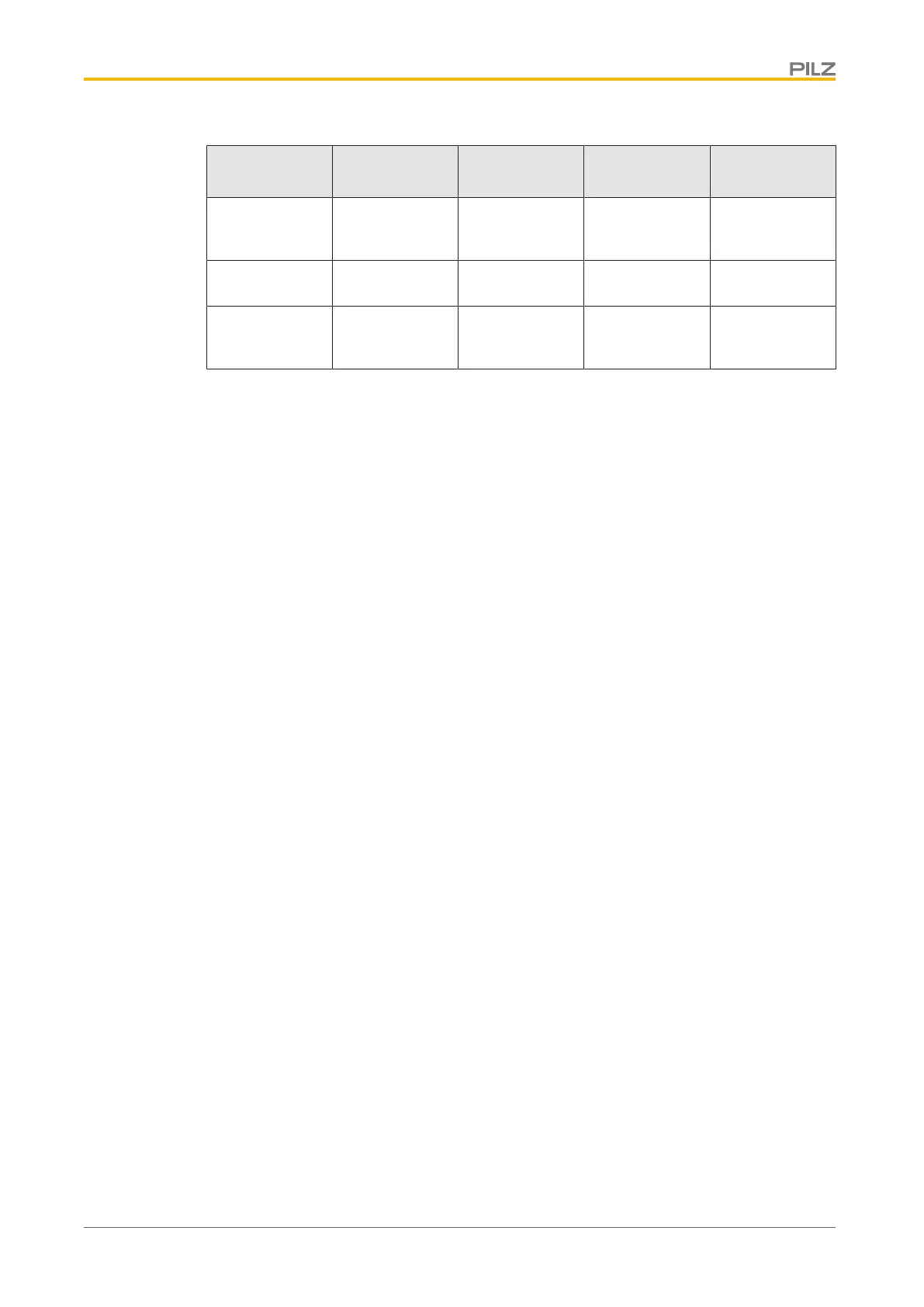

Connection Pin designation Device

Cable cross

section Conditions

Holding brake

(motor)

X9A All Min. 0.75 mm

Max. 1.5 mm²

600V, shielded,

check voltage

drop

+24V/XGND,

max. 30m

X3, X4 All Max. 1.5 mm² Check voltage

drop

Holding brake

+24V, max.

30m

X9B All Max. 1.5 mm² Check voltage

drop

* North America: max. 39m length, Europe: up to max. length

6.4 Wiring procedure

The following guidelines are intended to help you carry out the electrical installation in a

sensible order, without forgetting anything important.

Choice of cable

} Select cables in accordance with EN60204

Earthing, shielding

} Make sure that shielding and earthing are EMC-compliant

} Earth the mounting plate, the motor housing and the control system's ground terminal.

Information on the connection technology can be found under “Block diagram”.

Wiring

} Lay the power and control cables separately

} Incorporate the relay output for operational readiness (BTB) into the plant's safety cir-

cuit

} Connect the servo amplifier's digital inputs and outputs

} Connect the AGND earth (even if a fieldbus is used)

} If necessary, connect the analogue setpoint value

} Connect the encoder (feedback)

} Connect the expansion card

} Connect the motor cables

} Connect the shielding on both ends; use a motor choke if the cable runs are over 25m

} Connect the motor holding brake, connect the shielding on both ends

} If necessary, connect the external brake resistor (with fuse protection)

} Connect the 24 VDC supply voltage (for maximum permitted voltage values see

chapter entitled “Technical Details”)

} Connect the mains voltage (for maximum permitted voltage values see chapter entitled

“Technical Details”); for information on FI residual current devices see section entitled

“Residual current devices”)

} Connect the PC (see section entitled “Communications interfaces”)

Loading...

Loading...