ABL800 FLEX Operator's Manual 11. Troubleshooting

Forced Hold causes

Forced Hold mode suspends all the wet section activities in case certain analyzer

conditions occur. Until the condition has been corrected the analyzer cannot be

restarted.

Purpose

The causes for the Forced Hold mode are as follows:

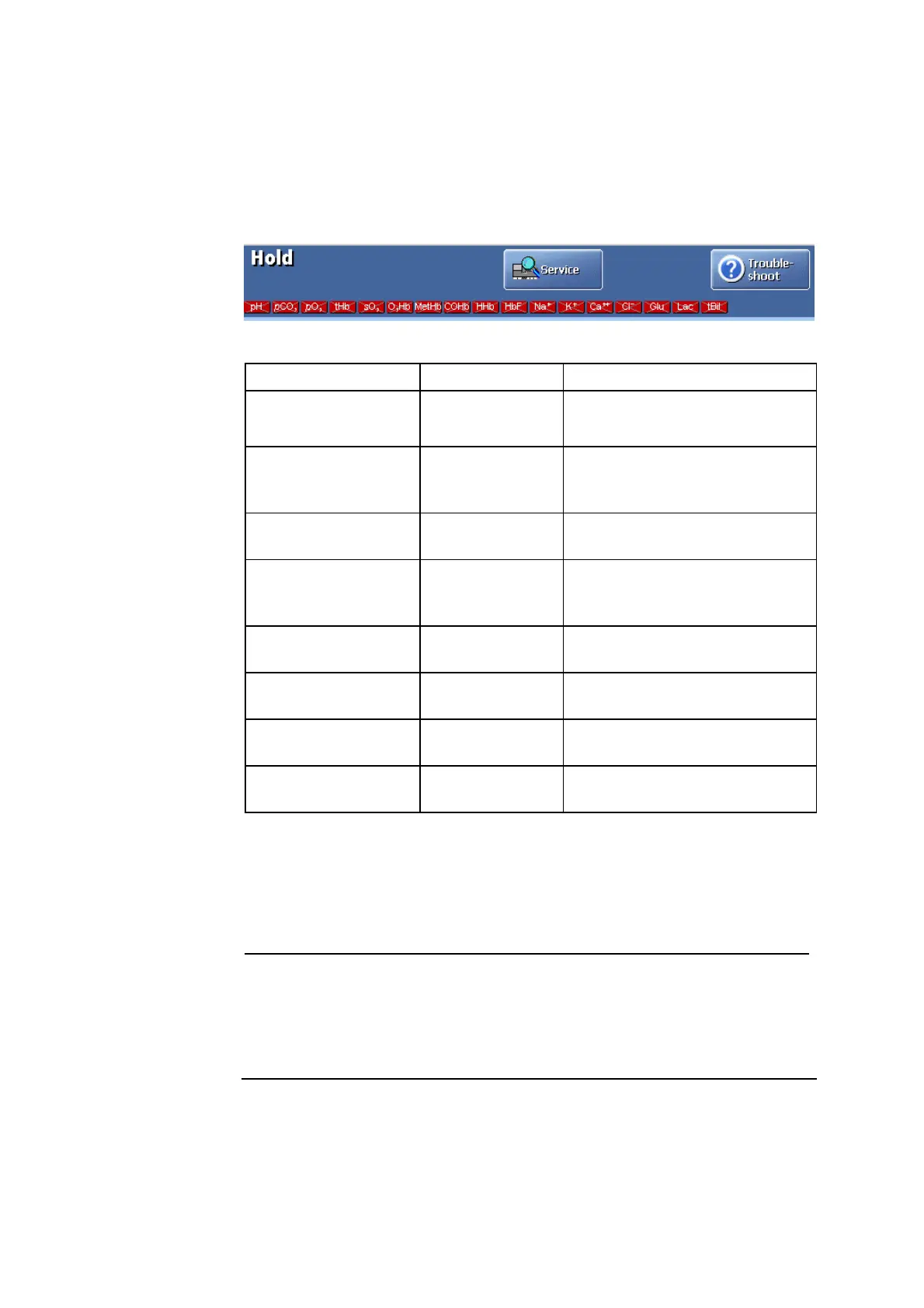

Condition Screen message Corrective action

Forced Standby Replace waste

container

Replace the waste container.

Press the Exit Standby button.

Rinse error Rinse Error Replace the Rinse Solution bottle

– see the procedure in chapter 7:

Replacements.

Operator intervention

required

Intervention

Required

Check Analyzer Status and

remedy the condition/error.

Cover to the measuring

modules removed or

the window opened.

Cover removed or

window opened

Verify the cover is properly

mounted and the window shut

prior to restart.

Both inlet flaps

removed.

Inlet flaps

removed

Verify the inlet flaps are properly

mounted prior to restart.

The inlet cannot obtain

proper position.

Inlet positioning

error

Contact service representative.

Inlet calibration failed Inlet calibration

error

Perform the procedure described

on the next page.

Leakage test failed Leak detected Perform the procedure described

on the next page.

This condition occurs when the calibration of the inlet fails, most likely caused by

a problem with the inlet components.

Inlet calibration

error

To correct the error, do the following:

Step Action

1.

Remove the analyzer cover and the inlet flaps.

2.

Check that the inlet probe and gasket are mounted properly.

3.

Remove the inlet gasket and check for wear or damage. Replace as

required.

Continued on next page

11-5

Loading...

Loading...