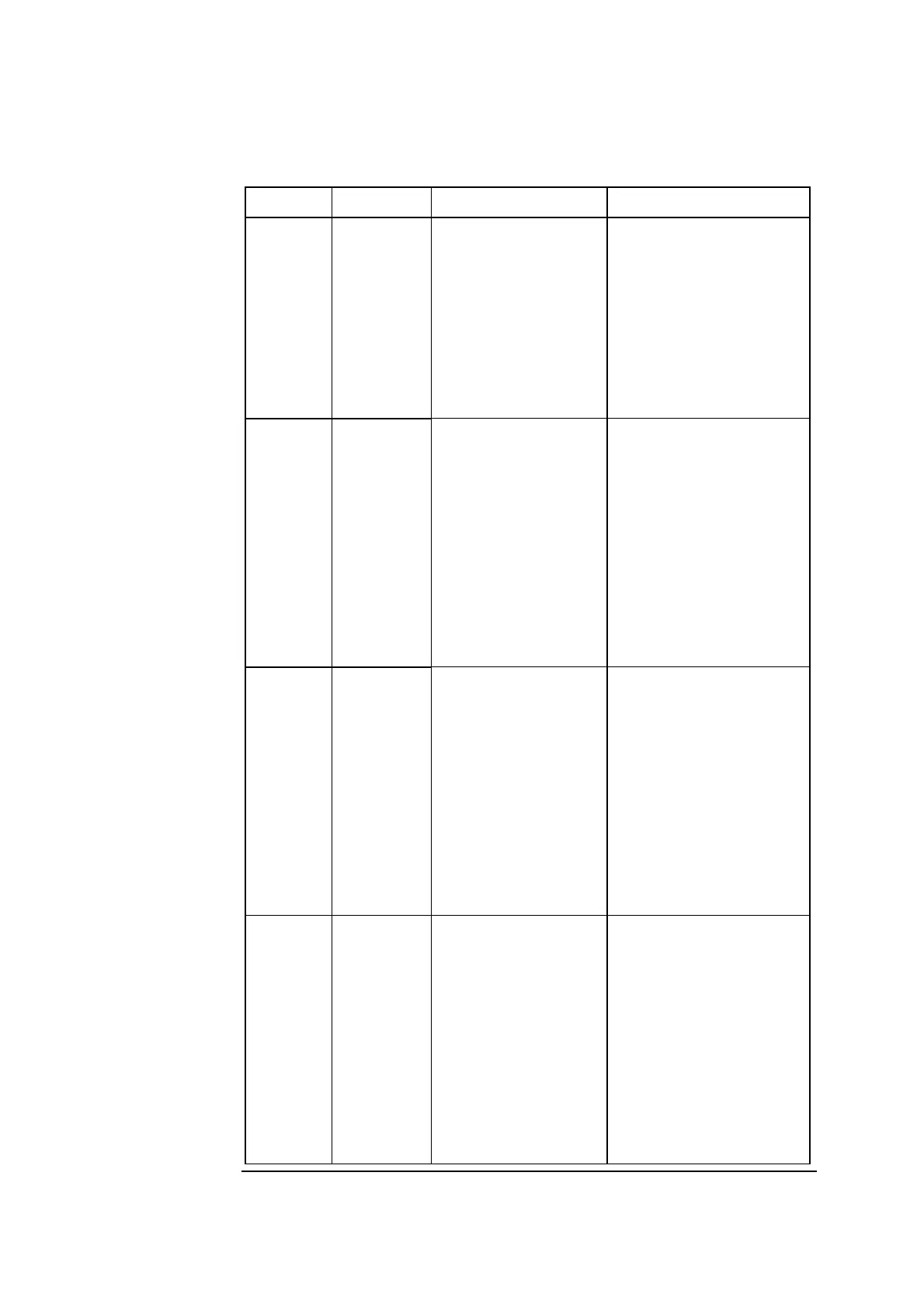

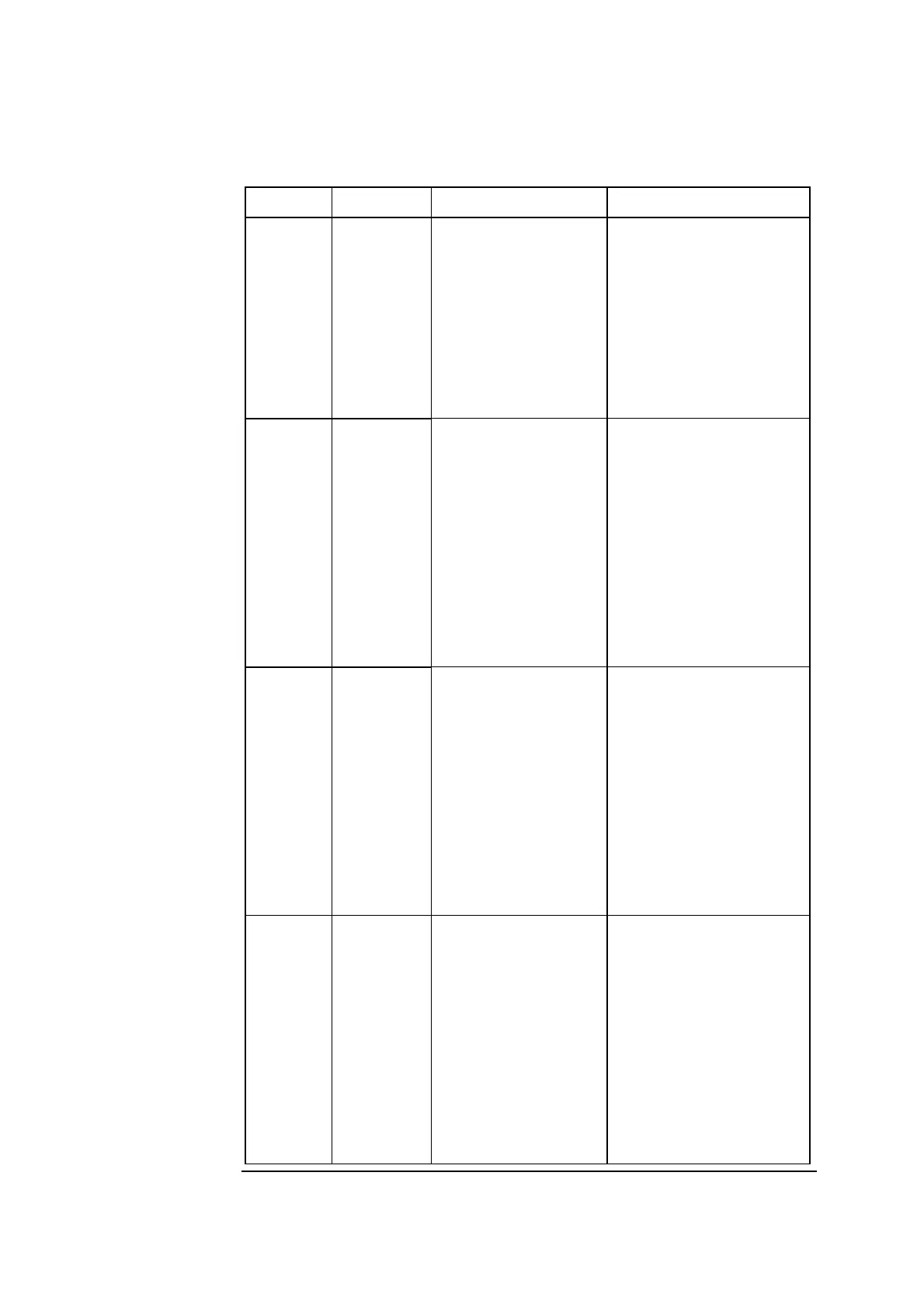

ABL800 FLEX Operator's Manual 11. Troubleshooting

Analyzer messages, Continued

Messages at

manager level

(continued)

No. Message Interpretation Operator action

920-922 Module not

filled within

time limit in

wash with

cleaning

Module did not fill

properly with cleaning

solution.

- Check the solution

containers for adequate

volume. Replace as

required.

- Perform the Fluid

Transport Troubleshooting

procedure.

Removal condition:

Successful Rinse

923 Inlet not

refilled

properly

during bi-

directional

pump

calibration

The inlet module was

not filled properly

during bi-directional

pump calibration.

- Check Rinse Solution for

sufficient volume. Replace

as necessary.

- Perform Pump

Calibration.

- Perform the Fluid

Transport Troubleshooting

procedure.

Removal condition:

Successful pump

calibration.

924 Inlet's liquid

sensor to

Oxi's liquid

sensor

volume

could not be

confirmed 1

During pump

calibration,

measurement of

internal volume part

failed.

Causes the Fluid

Transport Control

program to abort.

- Check Rinse Solution for

sufficient volume. Replace

as necessary.

- Perform Pump

Calibration.

- Perform the Fluid

Transport Troubleshooting

procedure.

Removal condition:

Successful pump

calibration.

925 Inlet's liquid

sensor to

Oxi's liquid

sensor

volume

could not be

confirmed 2

During pump

calibration,

measurement of

internal volume part

failed.

Causes the Fluid

Transport Control

program to abort.

- Check Rinse Solution for

sufficient volume. Replace

as necessary.

- Perform Pump

Calibration.

- Perform the Fluid

Transport Troubleshooting

procedure

Removal

condition:Successful pump

calibration.

Continued on next page

11-61

Loading...

Loading...