Order No.

35 MHz: F 8042

40 MHz: F 8043

41 MHz: F 8044

FX-30

First determine the ‘Slave’ channel or channels, i.e. the chan-

n

el into which a fixed value is to be mixed. Up to four functions

can be operated in this way. The functions can be selected

o

nce you have marked the corresponding field in the Function

S

elect menu which now appears. Mark the desired function,

a

nd leave the sub-menu by selecting ‘End’.

Y

our selection is displayed in the ‘Slave’ column.

After this the mode of the Offset mixer can be changed if

required. Two modes are available;

M

anual control:

When you operate the switch, the servo runs to the Offset

p

osition selected under ‘ON’, at the set speed and with the set

d

elay, and remains there as long as the switch is in the ‘On’

p

osition. The servo only moves again when the switch is

m

oved back to the ‘Off’ position; it then returns to the starting

p

oint - as set under ‘OFF’ - using the selected speed and

delay.

Timer control:

in this mode the servo runs to the prescribed ‘On’ position, as

described for manual control, when the switch is operated.

However - in contrast to manual control - it does not stay in

this position, but automatically returns to the starting point

when the pre-set dwell time (duration) has elapsed.

This Offset mixer is very convenient, and can be used to

implement sequences involving up to four functions, either

under manual or automatic control. Typical practical applica-

tions include the sequential retraction and extension of a scale

retractable undercarriage, whose functions can be controlled

very accurately using an Offset mixer. By setting the times

carefully, you can arrange for various wheel doors to open in

turn, after which the wheels then extend.

The Offset value can be entered as a percentage figure in the

‘Offset’ fields, separately for the ‘On’ and ‘Off’ states: mark the

appropriate field, and adjust the settings in the familiar way

using the arrow buttons. The adjustment range is +300% to -

300%. The default setting is 0%; marking the ‘Reset’ button

restores the defaults.

Fine-tuning is also available for the Offset mixers. The first

step is to define a transmitter control in the appropriate col-

umn, using the Transmitter Control Select menu as previously

described. After this you must set the effect range in the ‘Rate’

field using the arrow buttons; the adjustment range is +100%

to -100%. The default setting is 0%; marking the ‘Reset’ but-

ton restores the defaults.

The transmitter control you select for fine-tuning an Offset

mixer also has four operating modes; they are absolutely iden-

tical to those of a normal mixer.

You may also wish to optimise the servo transit speed for the

task in hand: the speed of the servo can be adjusted in small

increments, separately for the ‘there’ and ‘back’ directions.

The adjustment range is 0 to 27 increments. Please note: the

higher the number, the more slowly the servo moves. The

maximum value (27 increments) corresponds to a duration of

nine seconds. The default setting is always ‘0’. When you mark

one of the fields ‘THERE’ or ‘BACK’, the button fields for the

arrows appear at the right margin. It is possible to make

adjustments in steps of one increment or ten increments.

Pressing the ‘Reset’ button restores the default setting.

A delay time can be programmed using virtually the same pro-

cedure.

Delays in the range 0.0 to 9.0 seconds can be set, separately

for the ‘Start’ and ‘Stop’ phases.

Pressing the double-arrow buttons increases or reduces the

d

elay by one second; operating the single-arrow buttons pro-

d

uces increments of 0.1 second.

T

he programming of an Offset mixer is concluded by activat-

ing a switch using the standard procedure: mark the corre-

sponding button field in the bottom line, and define the switch

in the Switch Select menu which then appears. The direction

of effect of the switch can also be set in the usual way. The

status of the mixer is displayed as ‘On’ or ‘Off’ - according to

the position of the switch - in the left field in the bottom line.

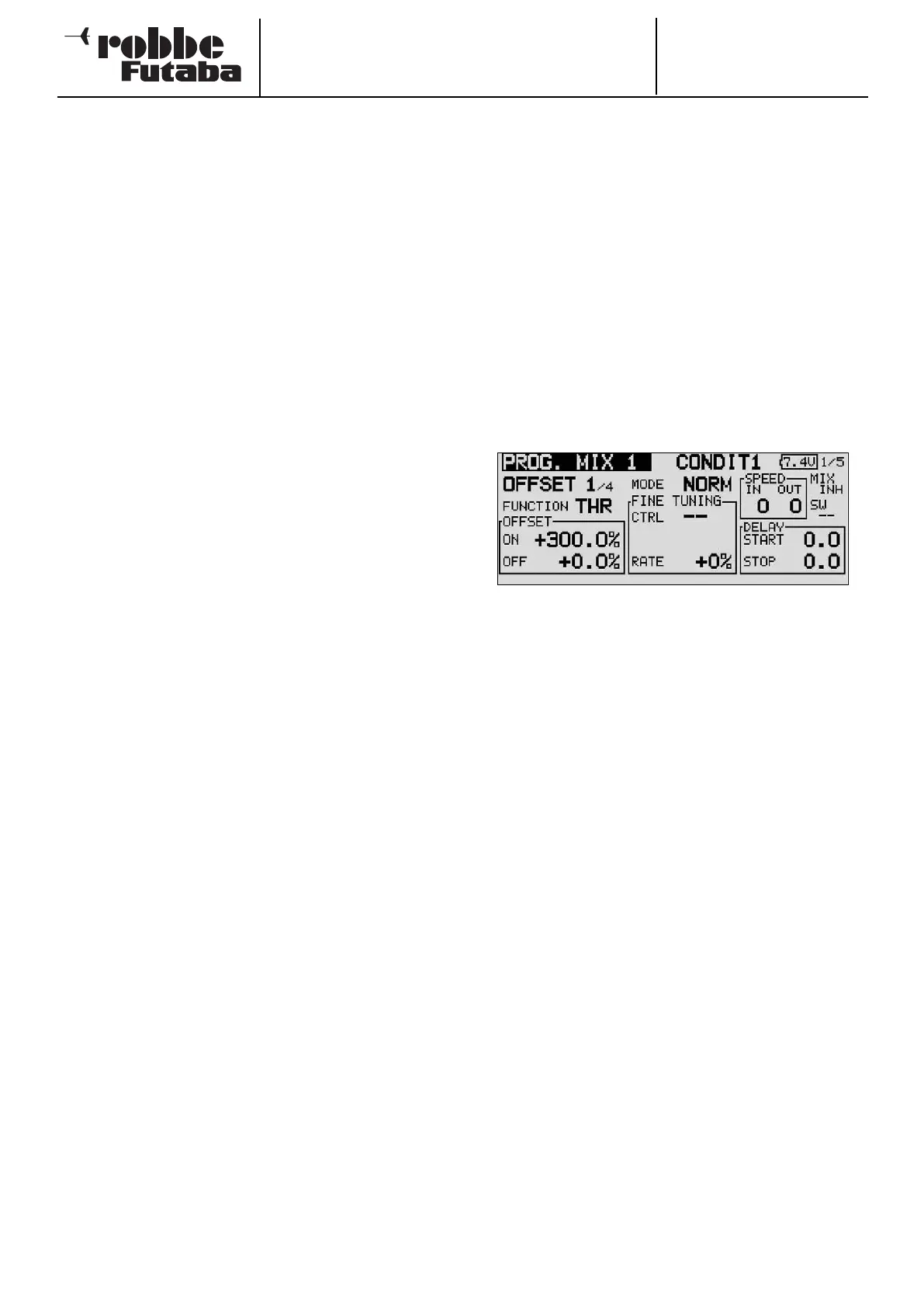

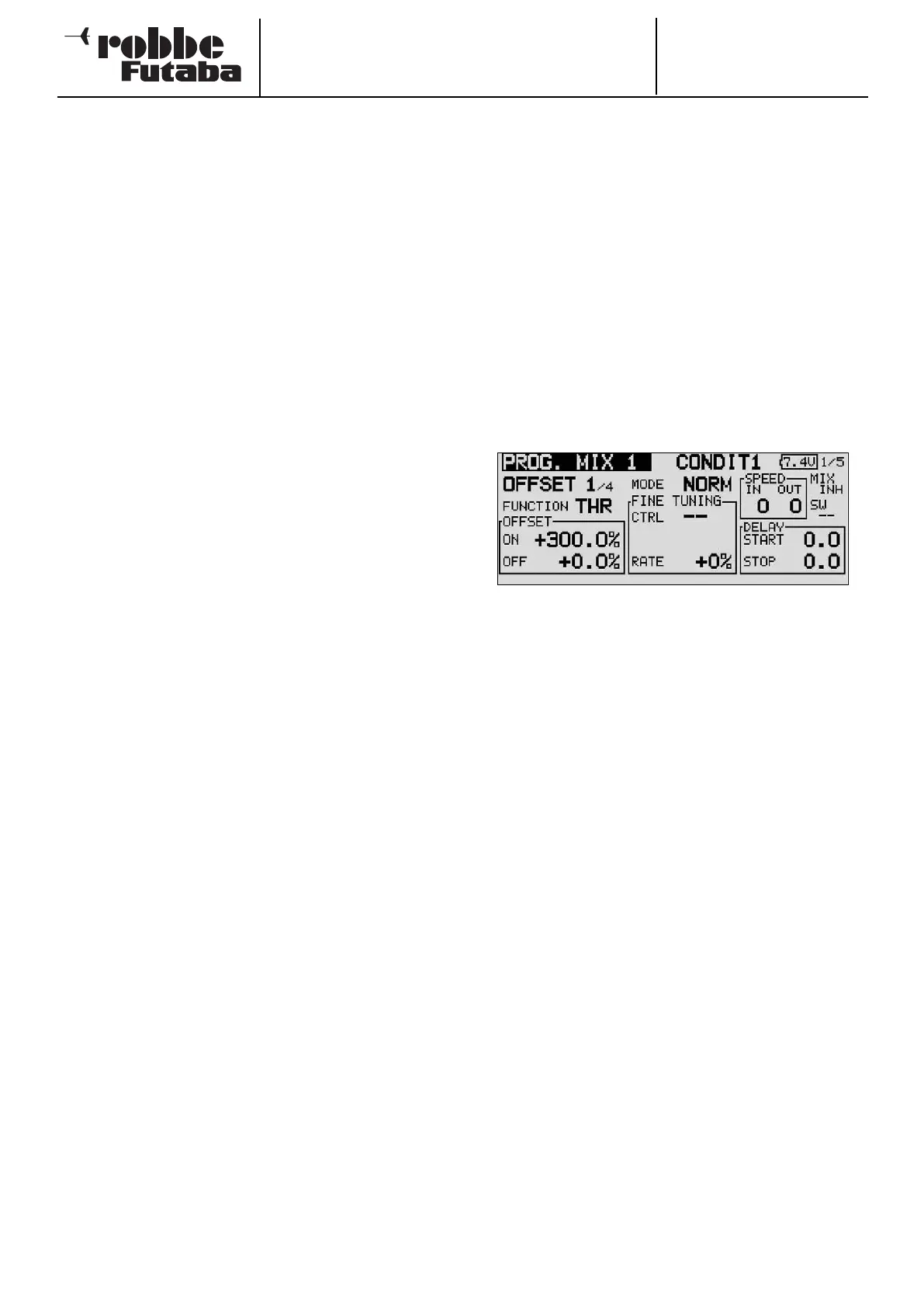

OFFSET MIXER AS MOTOR-CUT SWITCH

Offset mixers also offer the possibility of mixing a fixed value

i

nto the primary channel. This value can be up to 300%, as

shown in the screen shot.

This facility can be used, for example, to make absolutely cer-

tain that the motor of an electric-powered model cannot burst

into life unexpectedly, even if you move the throttle stick by

mistake; this is a very useful safety feature.

If you program an Offset mixer, and set the Offset value to -

300%, the throttle stick can be moved to any position without

the motor starting, because it is impossible for the stick travel

to override the value set by the Offset mixer.

The motor can then only be controlled in the normal way if you

first disable the Offset mixer by operating the associated

switch. This switch is not interrogated during the safety switch

query when the transmitter is switched on.

46

Loading...

Loading...