NOTE

T

he configurable object resolution has an influence on the protective field range availa‐

ble. The finer the object resolution configured for the safety laser scanner, the shorter

the available protective field range.

The protective field range is shown to you, see "P

arameters for the safety laser scan‐

ner", page 104.

Multiple sampling

DANGER

H

azard due to lack of effectiveness of the protective device

Persons or parts of the body to be protected may not be recognized or not recognized in

time in case of non-observance.

A higher multiple sampling increases the response time.

b

Make a note of the new response time of the safety laser scanner in Safety

Designer.

b

Adjust the minimum distance from the hazardous point to the new response time.

Multiple sampling indicates how often an object has to be scanned before the safety

la

ser scanner responds. A higher multiple sampling reduces the possibility that insects,

weld sparks or other particles cause the machine to be shut down. You will increase the

machine’s availability.

A multiple sampling of 2 is the minimum setting.

b

Increase the multiple sampling up to 16.

✓

An object must be this many times.

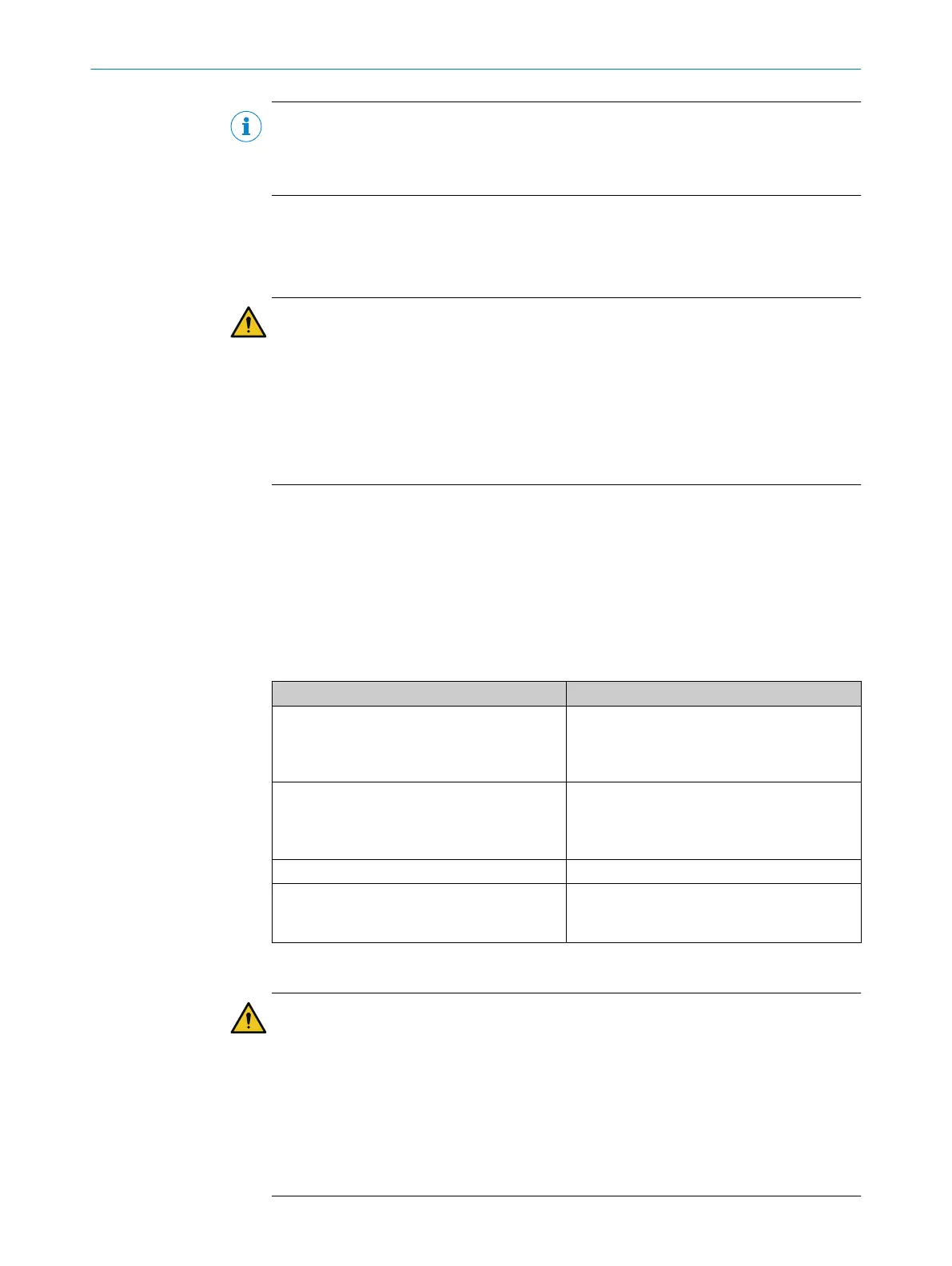

Table 14: Recommended multiple sampling

Application Recommended multiple sampling

Stationary application: such as horizontal haz‐

ar

dous area protection or vertical hazardous

point protection under clean ambient condi‐

tions

2×

Stationary application: such as vertical access

pr

otection

Only 2-time multiple sampling may be used for

vertical access protection.

2×

Mobile application 4×

Stationary application: such as horizontal haz‐

ar

dous area protection under dusty ambient

conditions

8×

Multiple sampling after monitoring case switching

DANGER

H

azard due to lack of effectiveness of the protective device

If combined with very short switchover times, higher multiple sampling after switching

between monitoring cases can result in a person or part of their body not being

detected.

b

Make sure that every monitoring case is active for at least the amount of time

required for detection by the safety laser scanner (setting for multiple sampling

after monitoring case switching multiplied by the configured scan cycle time

including the supplement due to interference protection).

CONFIGURATION 7

8021219/1ELL/2022-01-21 | SICK O P E R A T I N G I N S T R U C T I O N S | microScan3 – PROFINET

103

Subject to change without notice

Loading...

Loading...