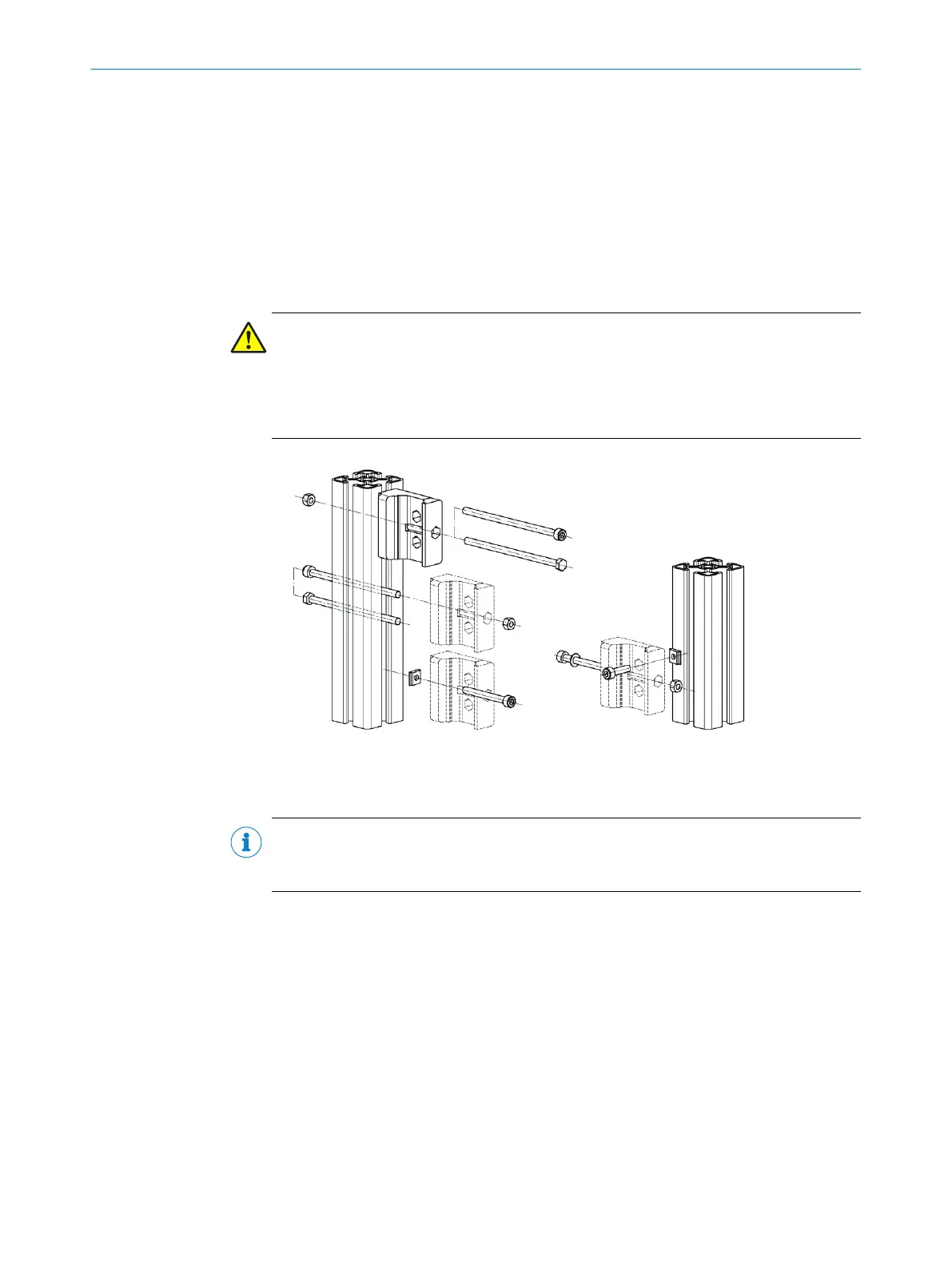

The QuickFix bracket consists of two parts, which are pushed into each other. An M5

screw is used to join both parts and to clamp the housing (sender or receiver).

Mounting can be carried out in two ways:

•

With the M5 screw through the QuickFix bracket to the machine or profile frame. A

screw nut or threaded hole is required on the machine or profile frame.

•

With the M5 screw through the machine or profile frame to the QuickFix bracket. A

screw nut is required for each QuickFix bracket.

When choosing the length of the M5 screw (hexagon head or cylinder head screw), con‐

sider the QuickFix bracket and the machine or profile frame.

CAUTION

Risk of injury from protruding screw thread!

When mounting through the machine or profile frame to the QuickFix bracket, the M5

screw can present an injury risk if too long.

b

Select an appropriate screw length to prevent any risk of injury from an overrun.

Figure 33: Mount QuickFix bracket to a profile frame

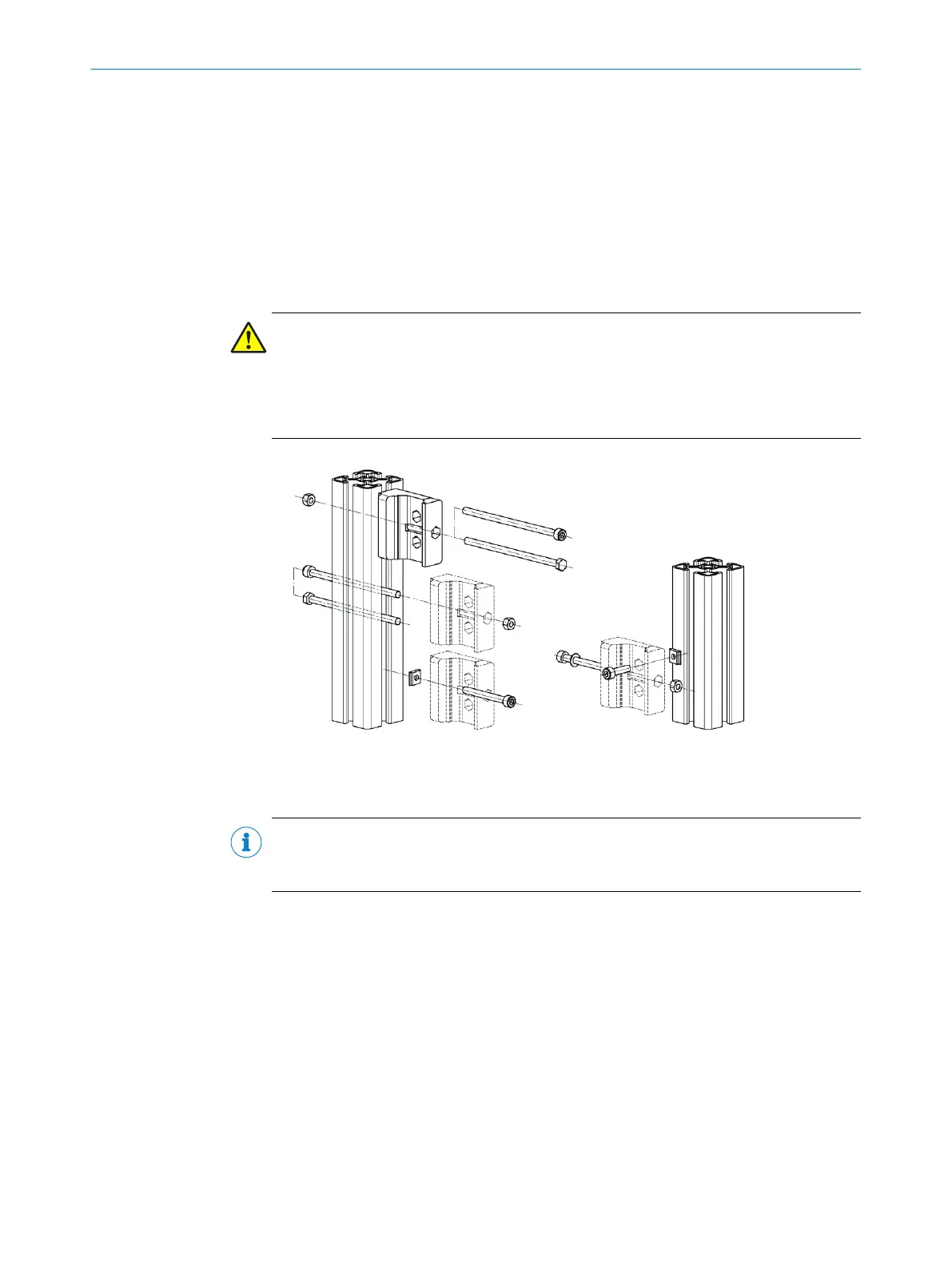

Mount QuickFix bracket to the back of a device column

NOTE

The QuickFix bracket has cable routing. Depending on the installation, the cable routing

can make mounting easier.

The sender and receiver are each mounted with two QuickFix brackets.

The QuickFix bracket consists of two parts, which are pushed into each other. An M5

screw is used to join both parts and to clamp the housing (sender or receiver).

You need two M5 screws per bracket if mounting them on the back.

b

Choose the length of the M5 screw such that it is possible to clamp the housing

(sender or receiver) in the QuickFix bracket.

4.3.2 Mounting the FlexFix bracket

In the FlexFix bracket, sender and receiver can be flexibly rotated by ±15°.

FlexFix brackets can be mounted in two ways:

•

On the side

•

On the back

MOUNTING 4

8017460.ZIK1/2017-02-13 | SICK O P E R A T I N G I N S T R U C T I O N S | MLG-2 Pro

41

Subject to change without notice

Loading...

Loading...