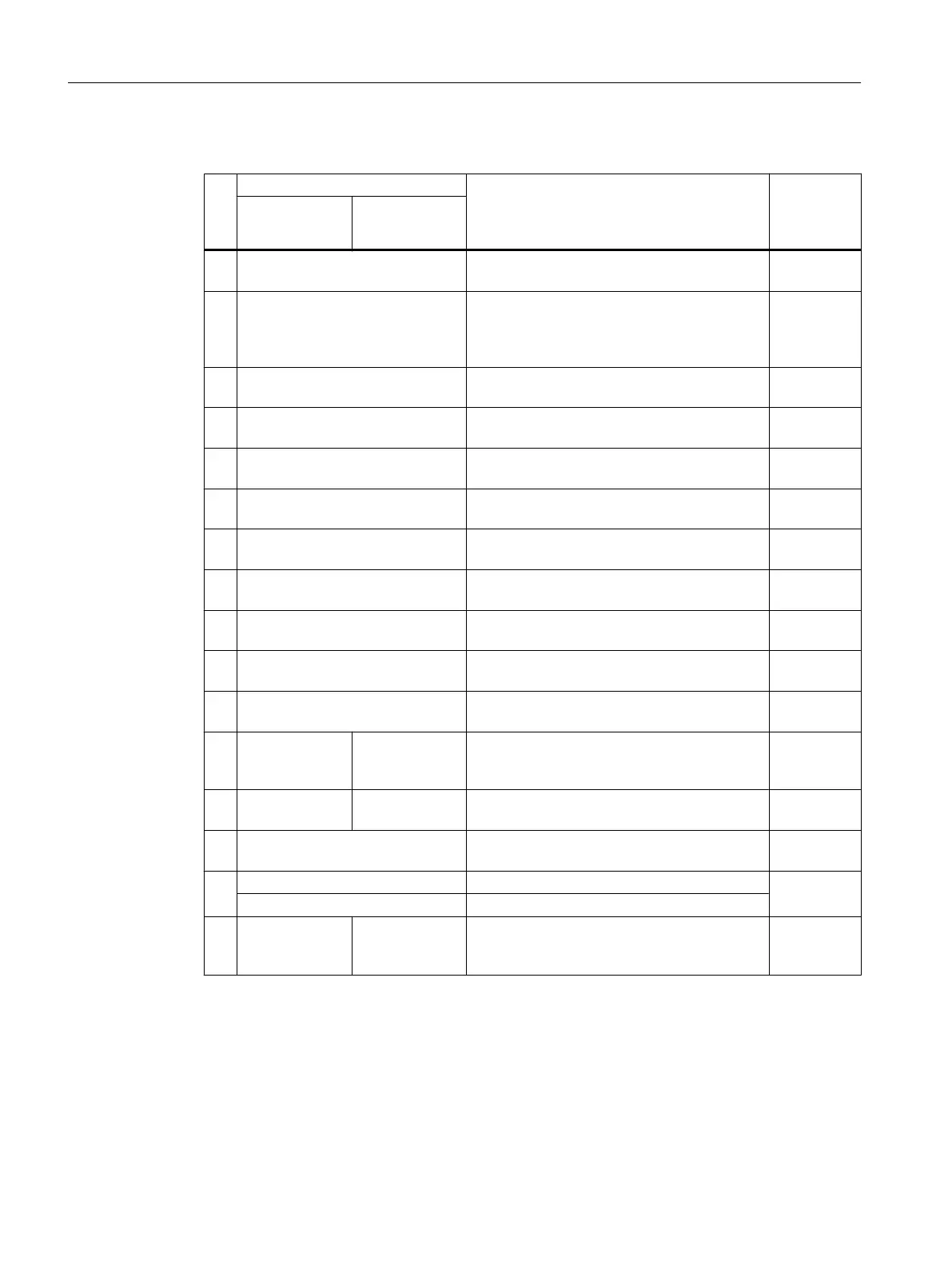

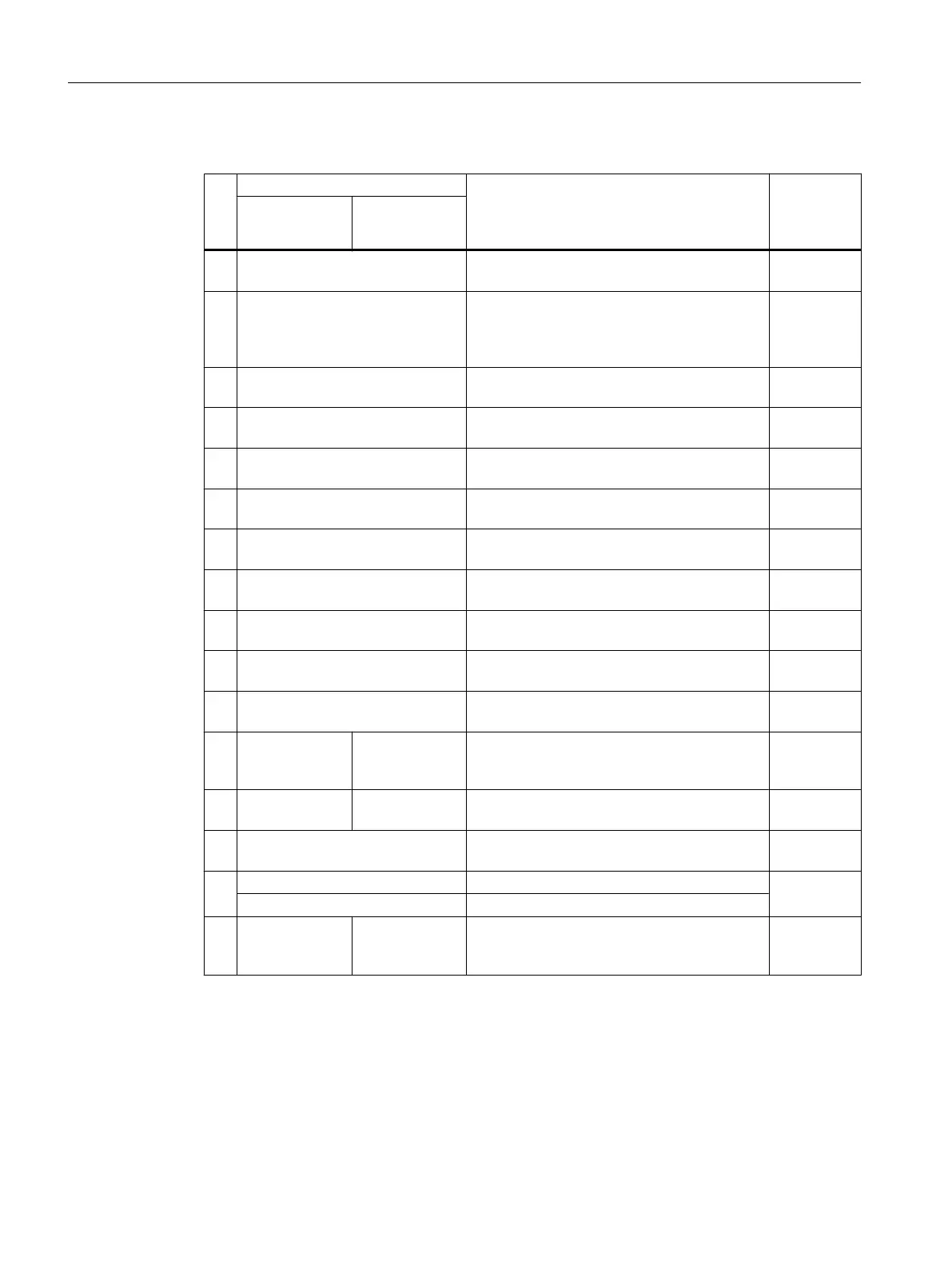

Status word 1 (ZSW1)

Bit Significance Comments Signal inter‐

connection

in the inver‐

ter

Telegram 20 All other tele‐

grams

0 1 = Ready to start Power supply switched on; electronics initial‐

ized; pulses locked.

p2080[0] =

r0899.0

1 1 = Ready Motor is switched on (ON/OFF1 = 1), no fault

is active. With the command "Enable opera‐

tion" (STW1.3), the inverter switches on the

motor.

p2080[1] =

r0899.1

2 1 = Operation enabled Motor follows setpoint. See control word 1, bit

3.

p2080[2] =

r0899.2

3 1 = Fault active The inverter has a fault. Acknowledge fault us‐

ing STW1.7.

p2080[3] =

r2139.3

4 1 = OFF2 inactive Coast down to standstill is not active. p2080[4] =

r0899.4

5 1 = OFF3 inactive Quick stop is not active. p2080[5] =

r0899.5

6 1 = Closing lockout active It is only possible to switch on the motor after

an OFF1 followed by ON.

p2080[6] =

r0899.6

7 1 = Alarm active Motor remains switched on; no acknowledge‐

ment is necessary.

p2080[7] =

r2139.7

8 1 = Speed deviation within the tol‐

erance range

Setpoint / actual value deviation within the tol‐

erance range.

p2080[8] =

r2197.7

9 1 = Master control requested The automation system is requested to accept

the inverter control.

p2080[9] =

r0899.9

10 1 = Comparison speed reached or

exceeded

Speed is greater than or equal to the corre‐

sponding maximum speed.

p2080[10] =

r2199.1

11 1 = current or

torque limit

reached

1 = torque limit

reached

Comparison value for current or torque has

been reached or exceeded.

p2080[11] =

r0056.13 /

r1407.7

12 ---

1)

1 = Holding

brake open

Signal to open and close a motor holding

brake.

p2080[12] =

r0899.12

13 0 = Alarm, motor overtemperature -- p2080[13] =

r2135.14

14 1 = Motor rotates clockwise Internal inverter actual value > 0 p2080[14] =

r2197.3

0 = Motor rotates counterclockwise Internal inverter actual value < 0

15 1 = CDS display 0 = Alarm, inver‐

ter thermal over‐

load

p2080[15] =

r0836.0 /

r2135.15

1)

If you change over from another telegram to telegram 20, then the assignment of the previous

telegram is kept.

Advanced commissioning

6.5 Drive control via PROFIBUS or PROFINET

Converter with the CU230P-2 Control Units

222 Operating Instructions, 09/2017, FW V4.7 SP9, A5E34257946B AE

Loading...

Loading...