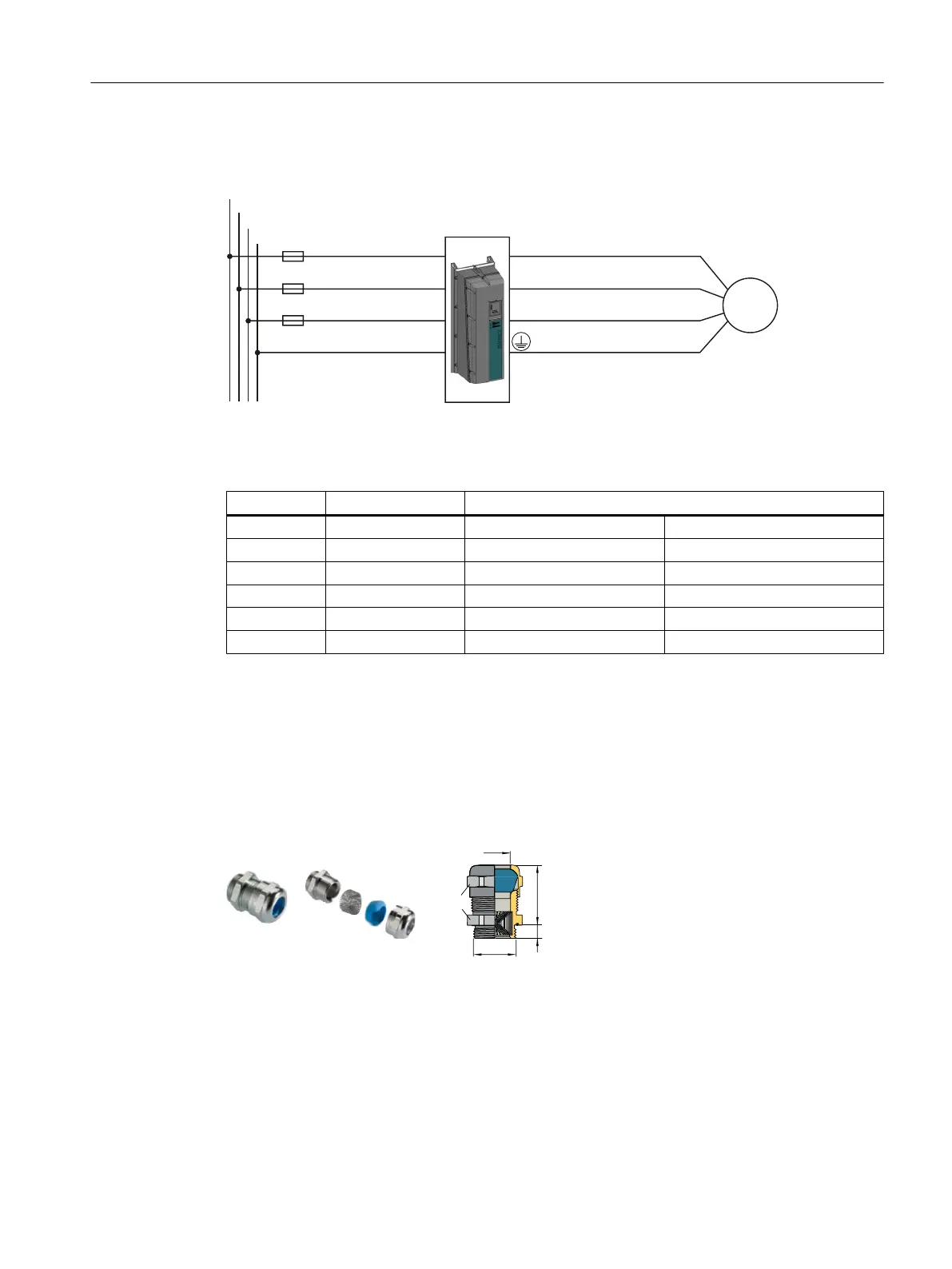

4.4.5 Connecting the inverter with the PM230 Power Module IP55

0

3RZHU

0RGXOH

3(

:

9

8/

/

/

3(

:

9

8

3(

/

/

/

Figure 4-11 PM230 Power Module IP55 connection overview

Table 4-26 Connection types, maximum conductor cross-sections and tightening torques

Inverters Connection Cross-section / tightening torque

FSA Terminal 1 … 2.5 mm

2

/ 0.5 Nm 18 … 14 AWG / 4.4 lbf in

FSB Terminal 2.5 … 6 mm

2

/ 0.6 Nm 14 … 10 AWG, 5.3 lbf in

FSC Terminal 6 …16 mm

2

/ 1.5 Nm 10 … 5 AWG / 13.3 lbf in

FSD Cable lug 10 … 35 mm

2

/ 6 Nm 5 … 2 AWG / 53 lbf in

FSE Cable lug 25 … 50 mm

2

/ 6 Nm 3 … 2 AWG / 53 lbf in

FSF Cable lug 35 … 120 mm

2

/ 13 Nm 2 … 4/0 AWG, 115 lbf in

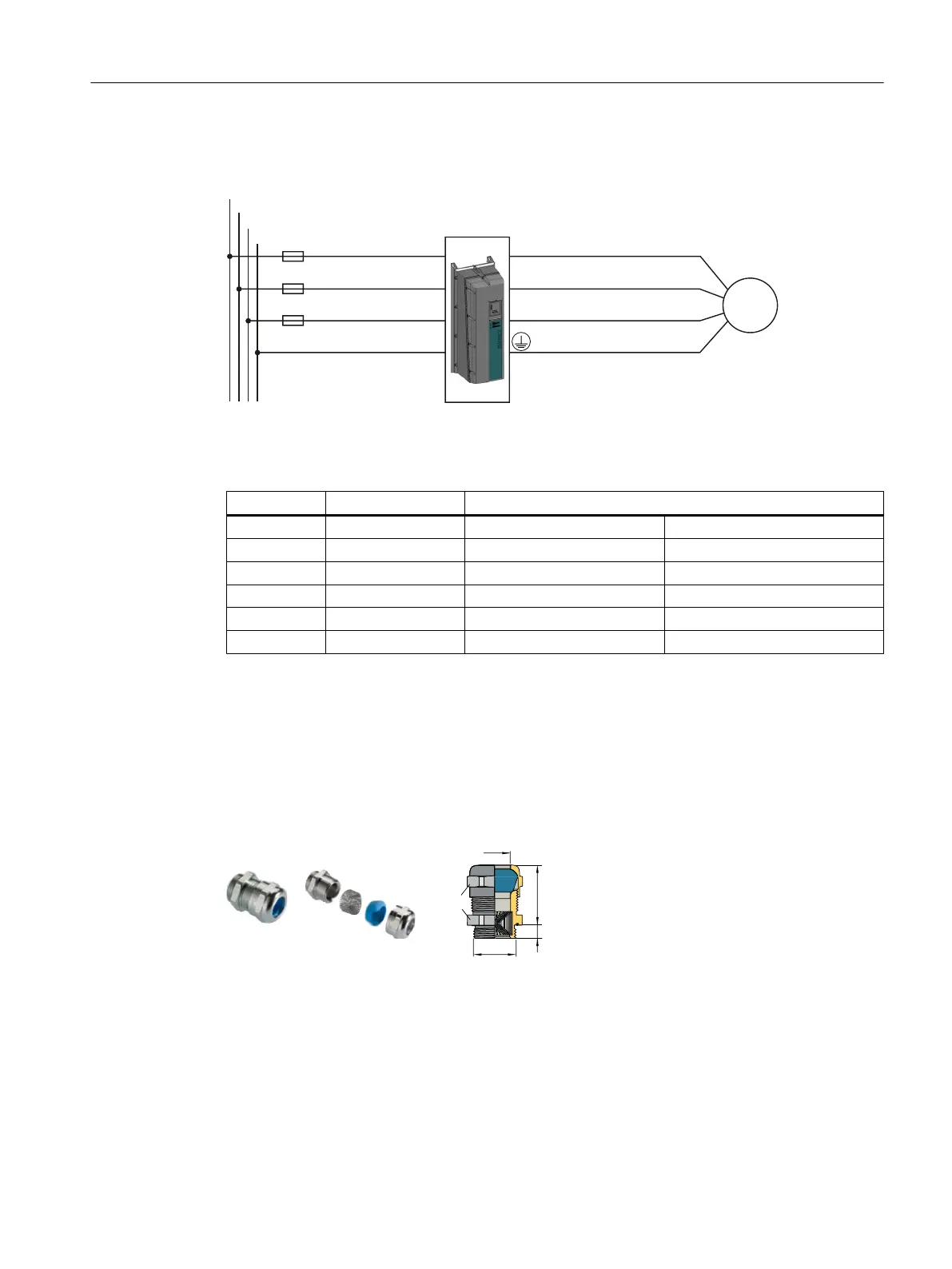

EMC cable glands

To meet the requirements of degree of protection IP55/UL, type 12, and to fulfill EMC

requirements, adhere to the following:

● Use EMC cable glands for the control cables.

● Make sure that the cable glands match the drill holes in the plate.

Figure 4-12 Example of an EMC cable gland (Blueglobe)

The EMC cable glands are not included in the scope of supply of the inverter. Rubber sleeves

for unused drill holes in the cable cover plate are included in the scope of supply.

Installing

4.4 Connecting the line supply and motor

Converter with the CU230P-2 Control Units

Operating Instructions, 09/2017, FW V4.7 SP9, A5E34257946B AE 89

Loading...

Loading...