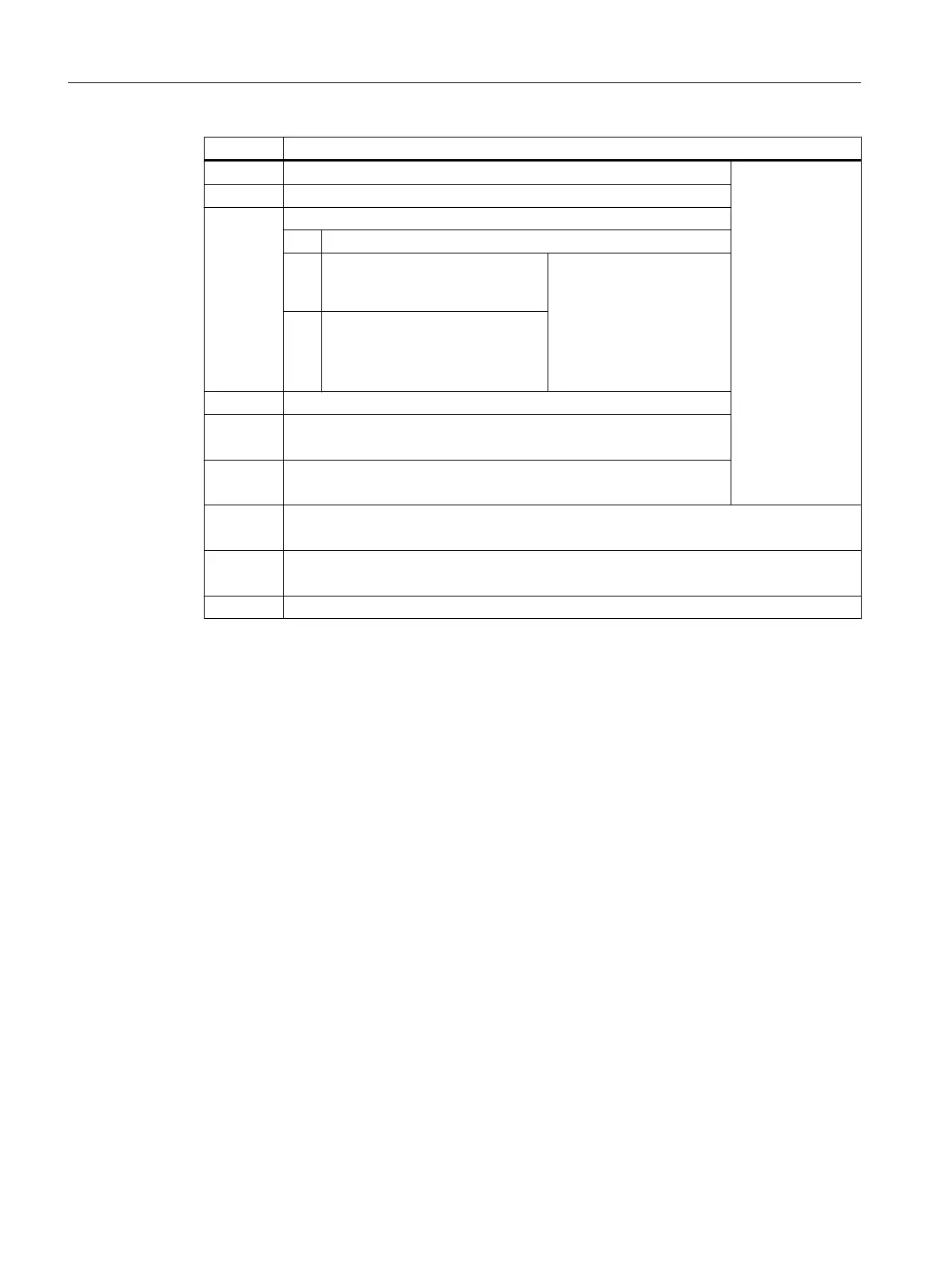

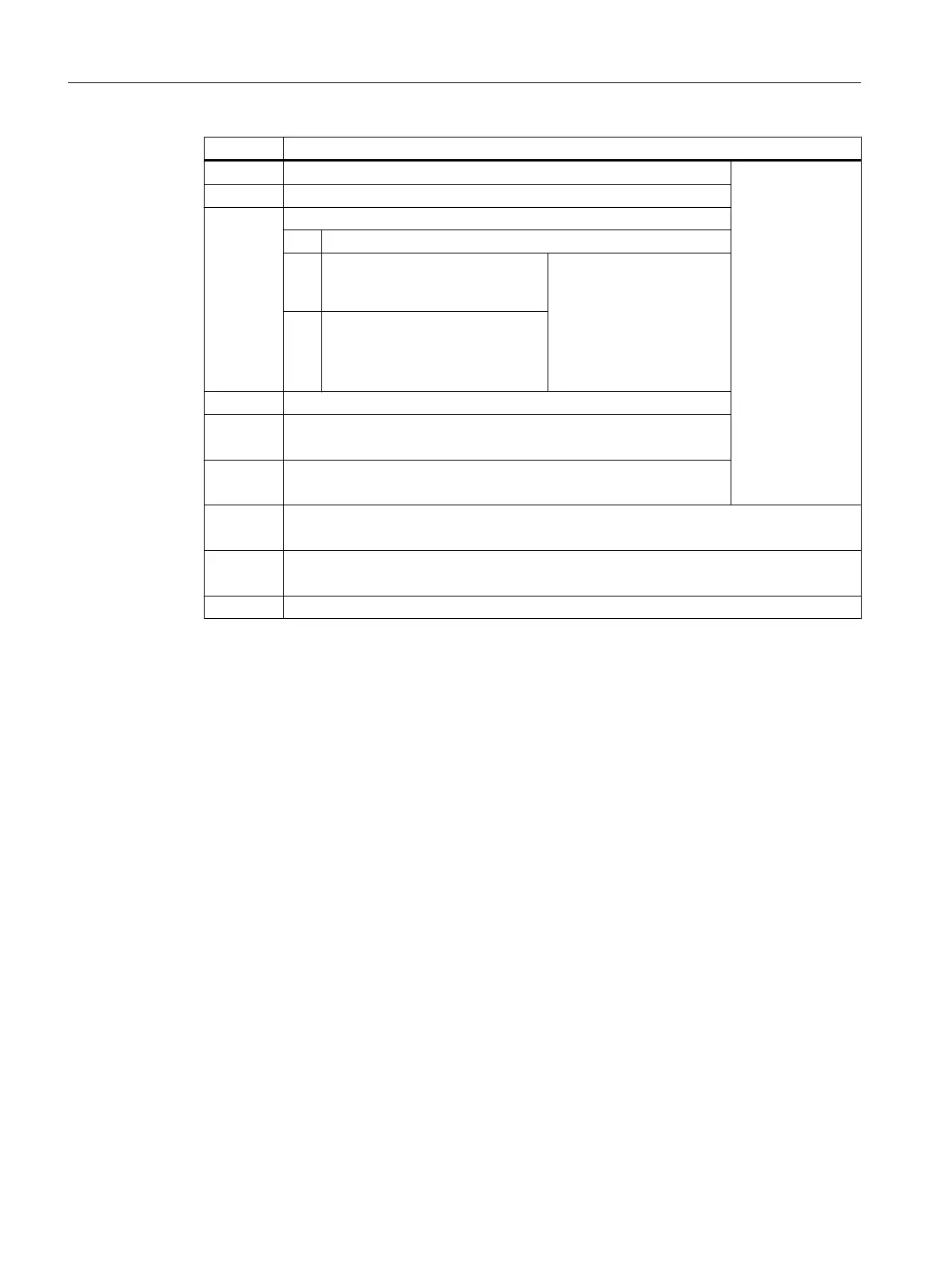

Parameter Description

p0318 Motor standstill current (factory setting: 0.0 A) After selecting a

synchronous re‐

luctance motor

(p0300 = 600) dur‐

ing the commis‐

sioning, the inver‐

ter sets the param‐

eters to values ap‐

propriate for the

motor type.

The parameters

are write-protec‐

ted for listed mo‐

tors (p0301 ≥ 0).

p0611 I2t motor model thermal time constant (factory setting: 0 s)

p0612 Mot_temp_mod activation

.00 1 signal: Activate motor temperature model 1

.08 1 signal: Activate extended mode,

overtemperature at rated load:

p0627

After commissioning, the

inverter sets

bit 8 = bit 12 = 1. If you load

the parameter settings for

firmware version ≤

V4.7 SP3 into the inverter,

bit 08 = bit 12 = 0 remain.

.12 0 signal: Ambient temperature =

p0625

1 signal: Ambient temperature =

p0613

p0627 Motor overtemperature, stator winding (factory setting: 80 K)

p5390 Mot_temp_mod 1/3 alarm threshold (factory setting: 110.0° C)

Motor temperature > p5390 ⇒ alarm A07012.

p5391 Mot_temp_mod 1/3 fault threshold (factory setting: 120.0° C)

Motor temperature > p5391 ⇒ fault F07011.

p0613 Mot_temp_mod 1/3 ambient air temperature (factory setting: 20° C)

Expected motor ambient temperature in °C for motor operation.

p0625 Motor ambient temperature during commissioning (factory setting: 20° C)

Motor ambient temperature in °C at the instant of the motor data identification.

r0632 Mot_temp_mod stator winding temperature [°C]

Further information is provided in the function charts 8016 and 8017 of the List Manual.

Advanced commissioning

6.29 Motor protection by calculating the temperature

Converter with the CU230P-2 Control Units

330 Operating Instructions, 09/2017, FW V4.7 SP9, A5E34257946B AE

Loading...

Loading...