Positioning Axes (P2)

17.2 Permanently assigned PLC axis

Turning, Milling, Nibbling

310 Function Manual, 11/2012, 6FC5397-1CP10-5BA0

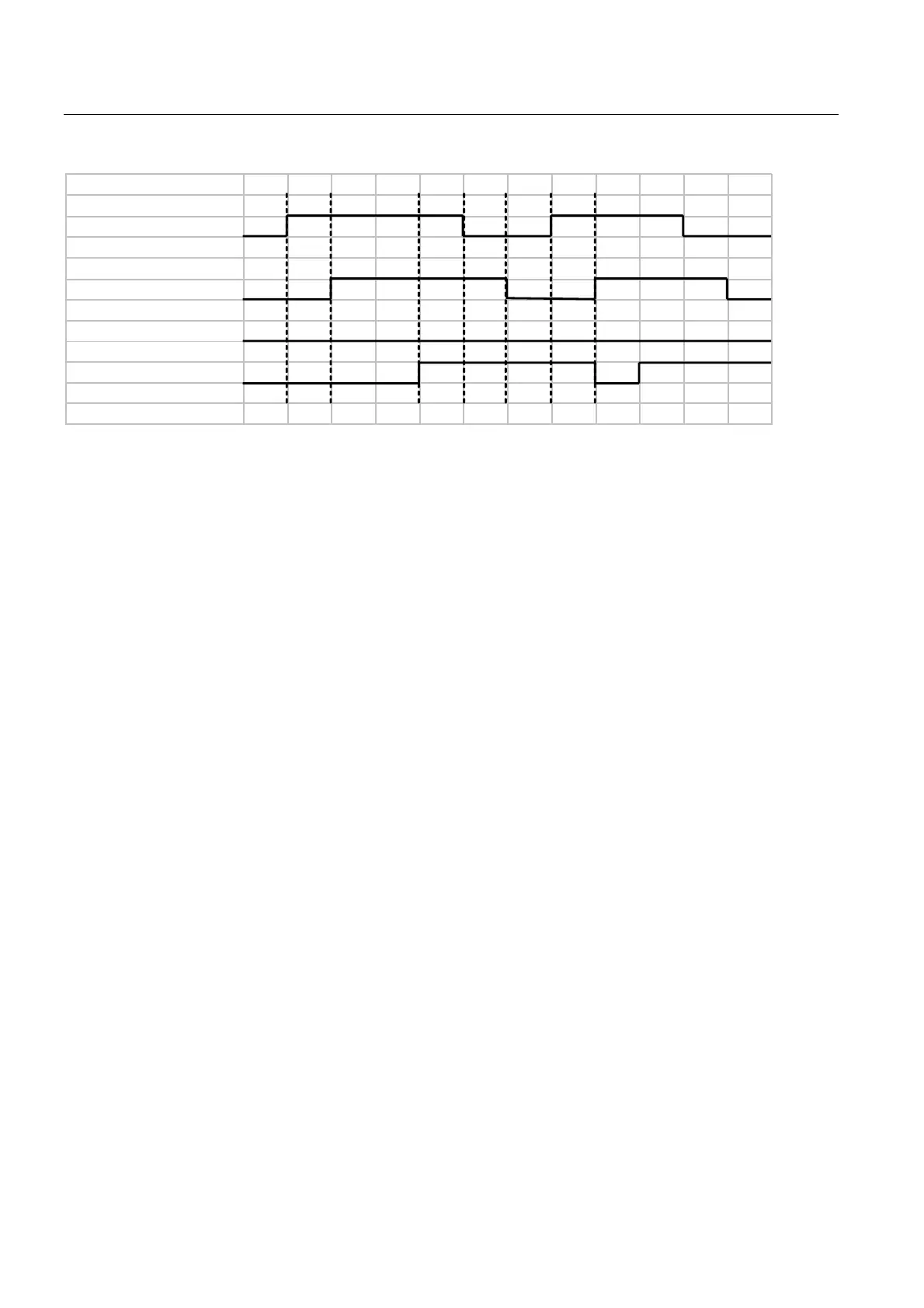

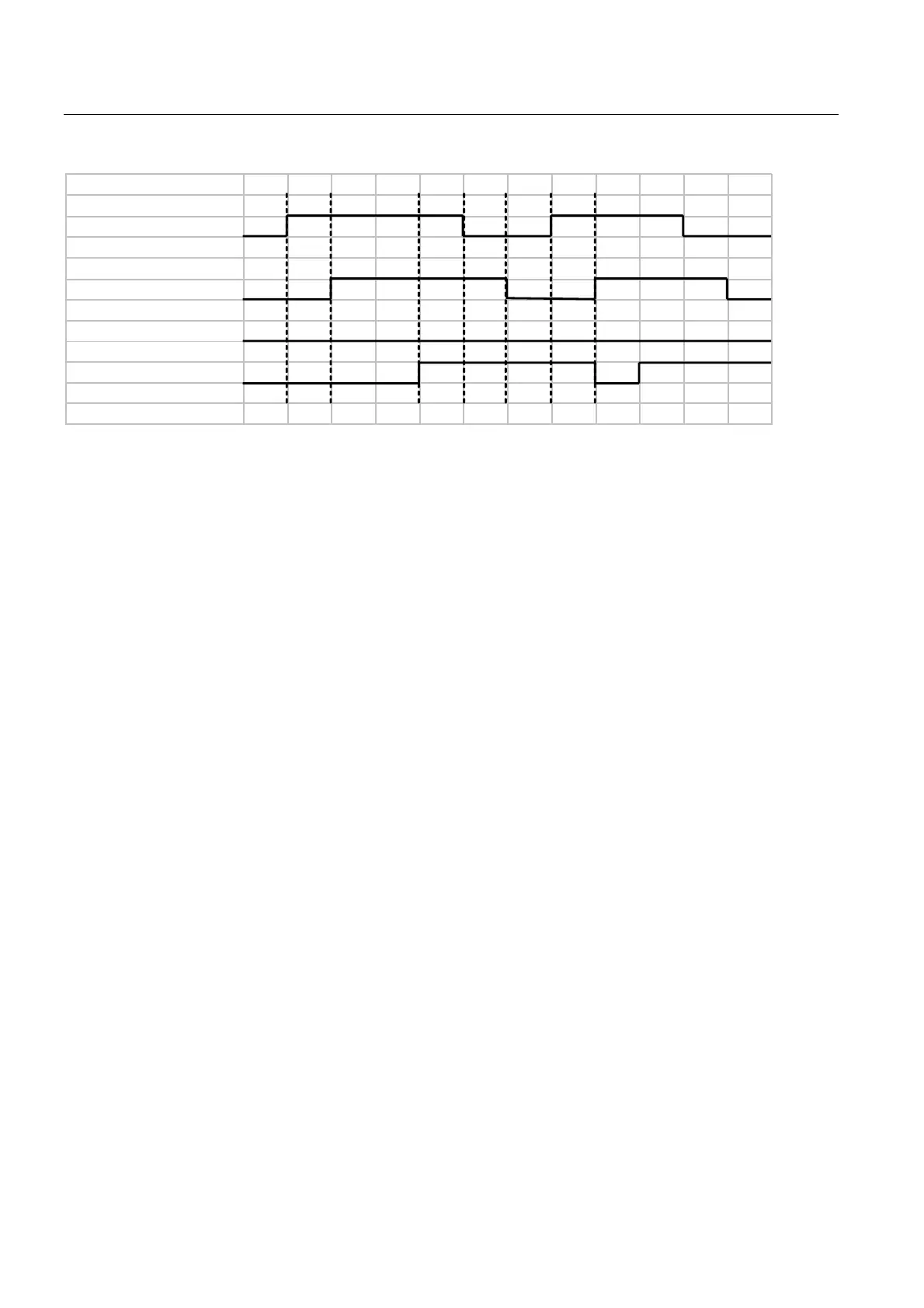

WR3/&D[LV

IURP3/&D[LV

3RVLWLRQLQJD[HVDFWLYH

3RVLWLRQUHDFKHG

6WDUW

(UURUV

Figure 17-2 Pulse diagram error condition

8. First function activation via positive edge of

Start

9.

Positioning axis active

= 1 shows that the function is active and that the output signals are

valid

10. Negative acknowledgement

Error

= 1 and

Positioning axis active

= 1

11. Reset function activation after receipt of acknowledgment

12. Signal change via function

13. Second function activation via positive edge of

Start

14.

Positioning axis active

= 1 shows that the function is active and that the output signals are

valid

Cancel

The PLC axis control cannot be aborted by means of parameter "Start", but only by means of

the axial interface signals (e.g. delete distancetogo). The axial interface also returns status

signals of the axis that may need to be evaluated (e.g. exact stop, traverse command).

Axis disable

With the axis disabled, an axis controlled via PLC axis control will not move. Only a

simulated actual value is generated. (Behavior as with NC programming).

Fault detection

If a PLC axis control could not be executed, this is indicated by the error signal

(V390x 3000.1 or V390x 3000.0) with 'logical 1'. The cause of the error is coded as an error

number.

Loading...

Loading...