6 Pro

rammin

the control

6

03/2006

6.9 Axes and spindles

6-123

© Siemens AG 2006 All Rights Reserved

SINUMERIK 840D/810D Start-Up Guide (IADC) – 03/2006 Edition

6.9.18 Spindle synchronization

The spindle must synchronize its position with the measuring system. It is al-

ways synchronized with the zero marker of the encoder or with a sensor signal

that is connected to the drive module of the SIMODRIVE 611D. MD 34200

ENC_REFP_MODE is used to specify which signal is used for the synchroniza-

tion (zero marker (0) or sensor (1))

S After activation of the control if the spindle is moved with a programming

command.

S The “Resynchronize spindle 1/2” signal removes the “Referenced/Synchro-

nized 1/2” signal that resynchronizes the spindles with the next reference

signal.

S After every gear step change (MD 31040: ENC_IS_DIRECT=0)

S The spindle goes out of synchronism if a speed above the encoder limit fre-

quency is programmed. When the speed drops to below the encoder limit

frequency, the spindle is re-synchronized. If the synchronized state has

been lost, it is impossible to implement functions such as rotational feedrate,

constant cutting velocity, tapping with and without compensating chuck, po-

sitioning and axis modes.

MD 34100: REFP_SET_POS (reference point value, zero marker position). This

MD is used to enter the position of the reference signal for synchronization.

MD 34090: REFP_MOVE_DIST_CORR (reference point move, zero marker

move)

The zero mark offset resulting from the synchronization process is entered here.

MD 34200: ENC_REFP_MODE (position measuring system type)

NST “Resynchronize spindle 1, 2” (DB31, ... DBX16.4 or 16.5)

NST “Referenced/synchronized” 1, 2” (DB31, ... DBX60.4 or 60.5)

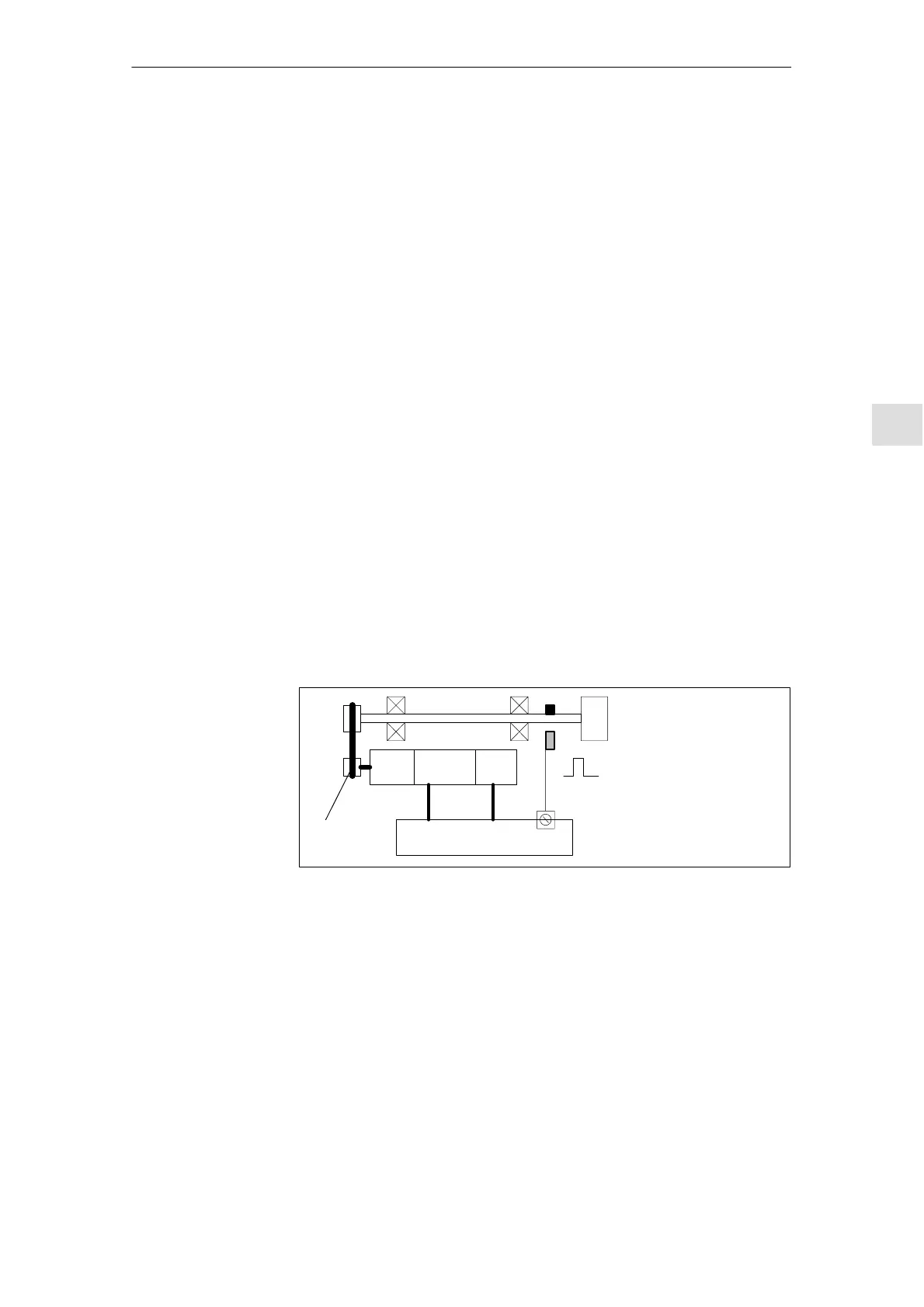

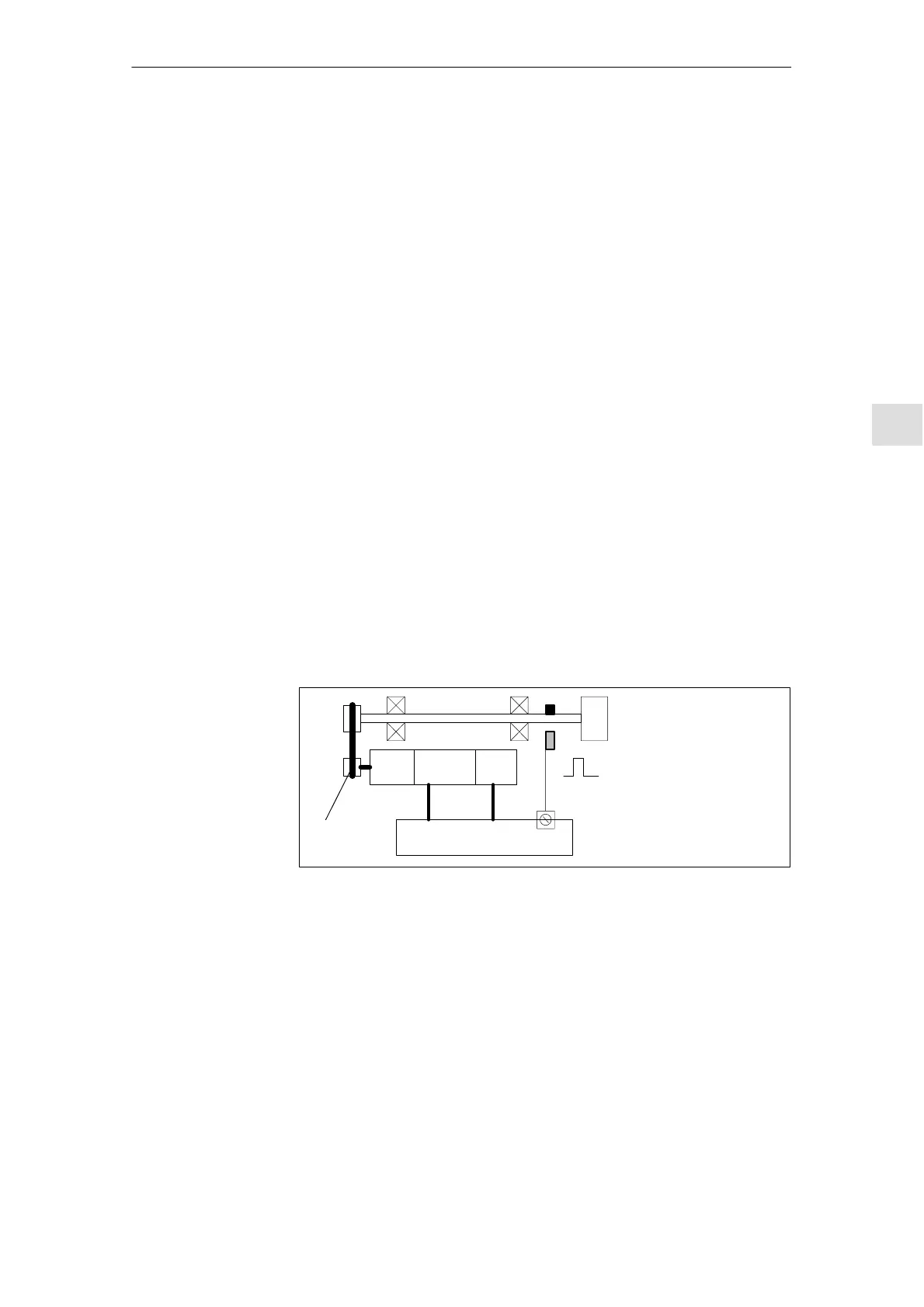

Motor Motor

encoder

MSD module SIMODRIVE 611D

Chuck

BERO

Power

connection

Motor enco-

der cable

Gearing

Toothed belt

Fig. 6-22 Synchronization via an external reference signal (BERO)

When is

synchronization

necessary?

Machine data and

interface signals

Loading...

Loading...