6 Pro

rammin

the control

6

03/2006

6.6 System data

6-67

© Siemens AG 2006 All Rights Reserved

SINUMERIK 840D/810D Start-Up Guide (IADC) – 03/2006 Edition

6.6 System data

6.6.1 Basic settings

The control works on the basis of clock cycles that are defined via machine

data. The system basic cycle is specified in seconds; the other cycle times are

obtained as multiples of the system basic cycle.

The clock cycles are optimized by default and should only be changed if the

requirements of the NCK cannot be met with the default values.

The following cycle times are used by default:

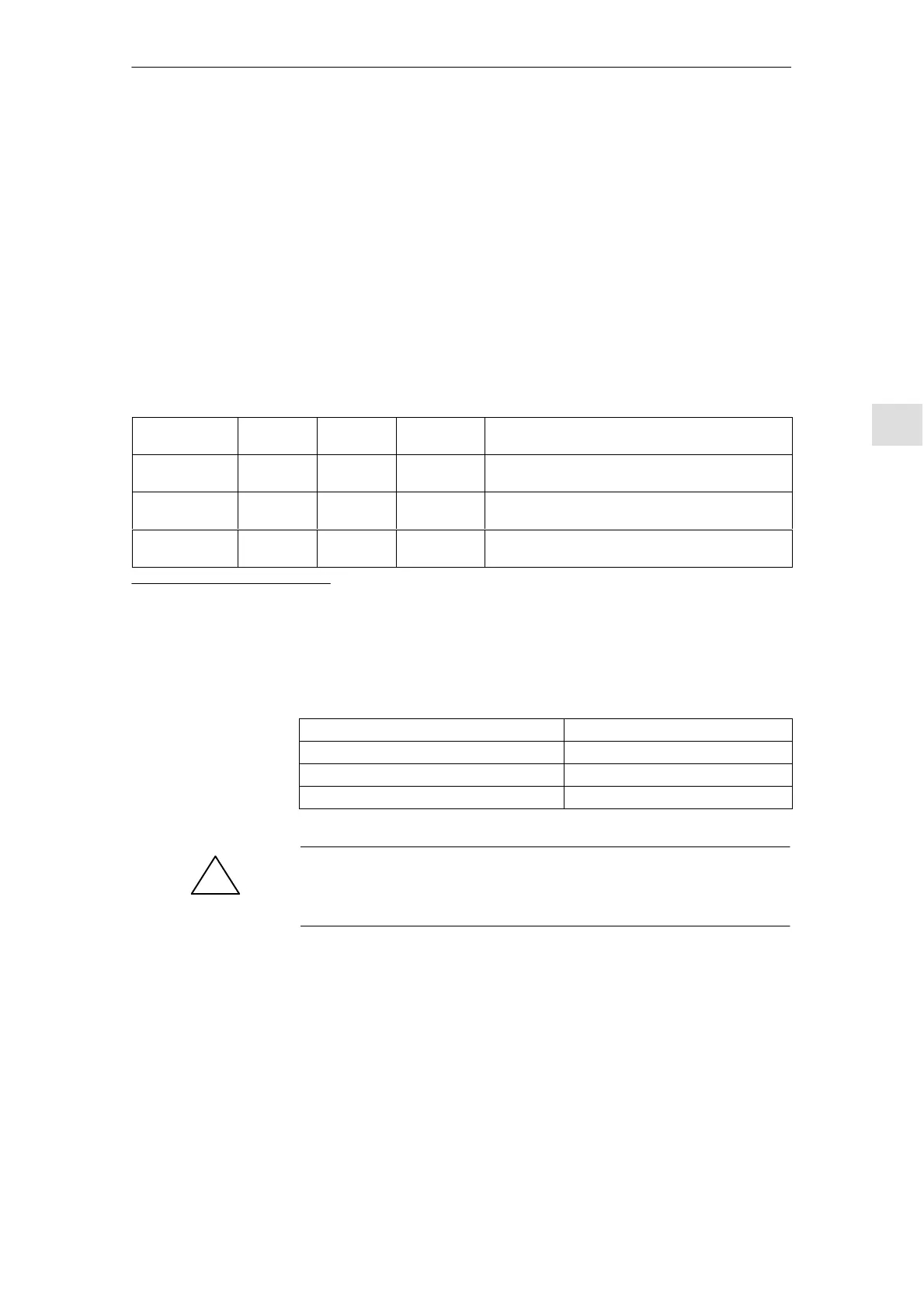

Table 6-10 Clock cycles – default values for the control

Cycle 840D

NCU 571

840D

NCU 572

840D

NCU 573

Setting via MD

System basic

cycle in s

6 ms 4 ms 4* / 8

#

ms MD 10050: SYSCLOCK_CYCLE_TIME

Position control

cycle as a factor

6 ms 4 ms 4* / 8

#

ms MD 10060: POSCTRL_SYSCLOCK_TIME_RATIO

Interpolator cy-

cle as a factor

18 ms 12 ms 12

*

/ 40

#

ms MD 10070: IPO_SYSCLOCK_TIME_RATIO

* with 2 channel and 12 axes

#

with > 2 channels

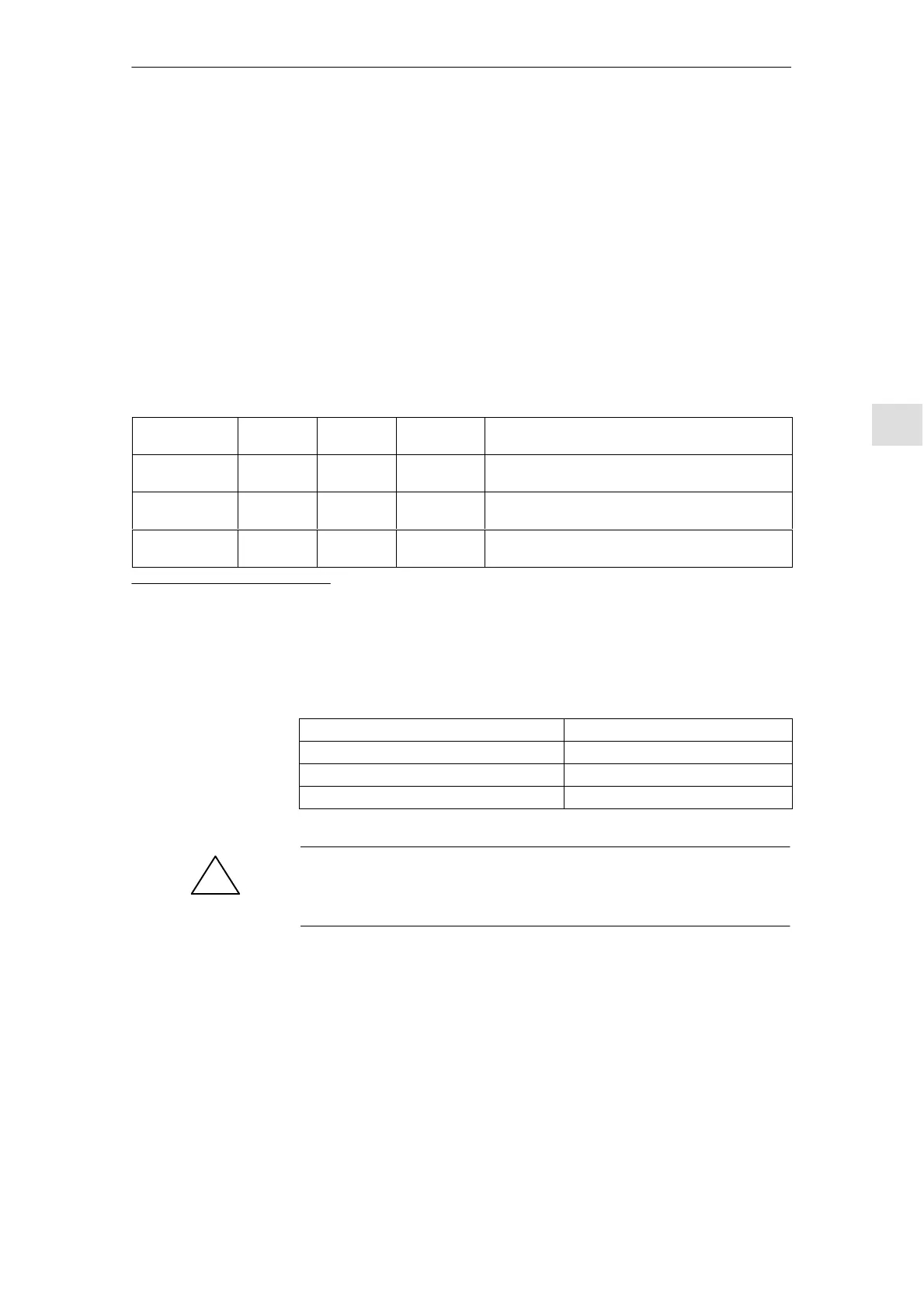

The machine data for cycle times is set as follows:

If MD ... = ... Then the ... = ...

SYSCLOCK_CYCLE_TIME = 0.002 System basic cycle = 2 ms

POSCTRL_SYSCLOCK_TIME_RATIO = 1 Position control cycle = 2 ms (1 2 ms)

IPO_SYSCLOCK_TIME_RATIO = 3 Interpolator cycle = 6 ms (3 2 ms)

!

Warning

If you have changed the clock cycles, check that the operating response of the

control is correct in all operating modes before ending the start-up process.

A control is switched from the metric system to an inch system with

MD 10240: SCALING_SYSTEM_IS_METRIC (basic system is metric).

The additional conversion factor is specified in

MD 10250: SCALING_VALUE_INCH (conversion factor for switching to the

INCH system, factor = 25.4).

After power ON the existing data is converted to inches and displayed. After

switchover data must be entered in inches.

Control clock

cycles

General example

for cycle settings

Switching from

metric to Inch

Loading...

Loading...