10

03/2006

10.4 Frequency response measurement

10-188

© Siemens AG 2006 All Rights Reserved

SINUMERIK 840D/810D Start-Up Guide (IADC) – 03/2006 Edition

10.4.3 Scanning position control loop

The behavior when transferring to the active position measuring system is

always analyzed. The NCK generates an error message if the function is activa-

ted for a spindle without position measuring system. Various lists of measuring

parameters are offered depending on which basic setting is selected.

1. Setting the traveling range monitoring and the enabling logic on the

main screen.

One of three different types of measurement can be selected:

S Reference frequency response

S Setpoint step change

S Setpoint ramp

2. Setting the necessary parameters on the measuring parameters screen

3. Displaying the measurement result on screen using the Display soft key

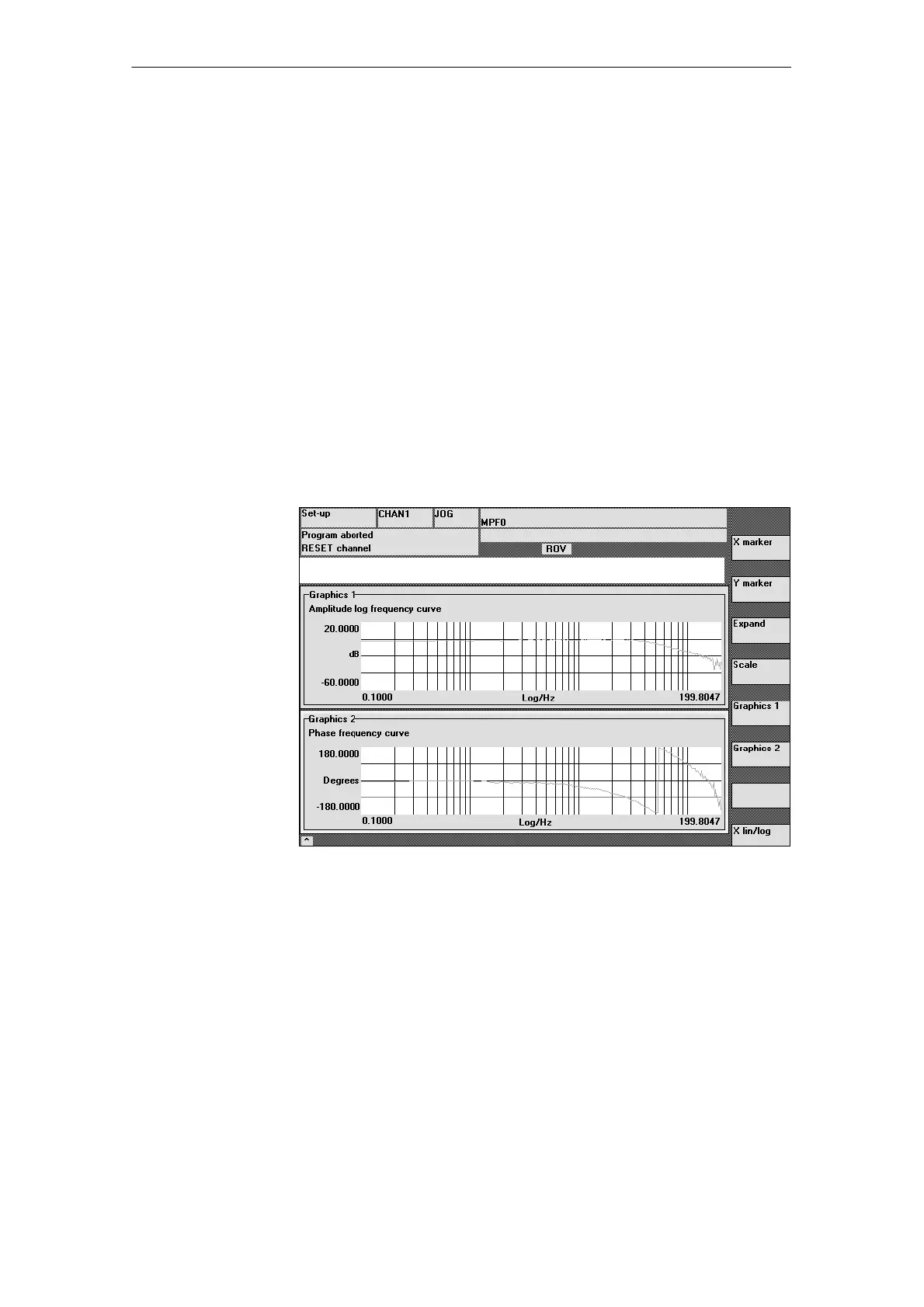

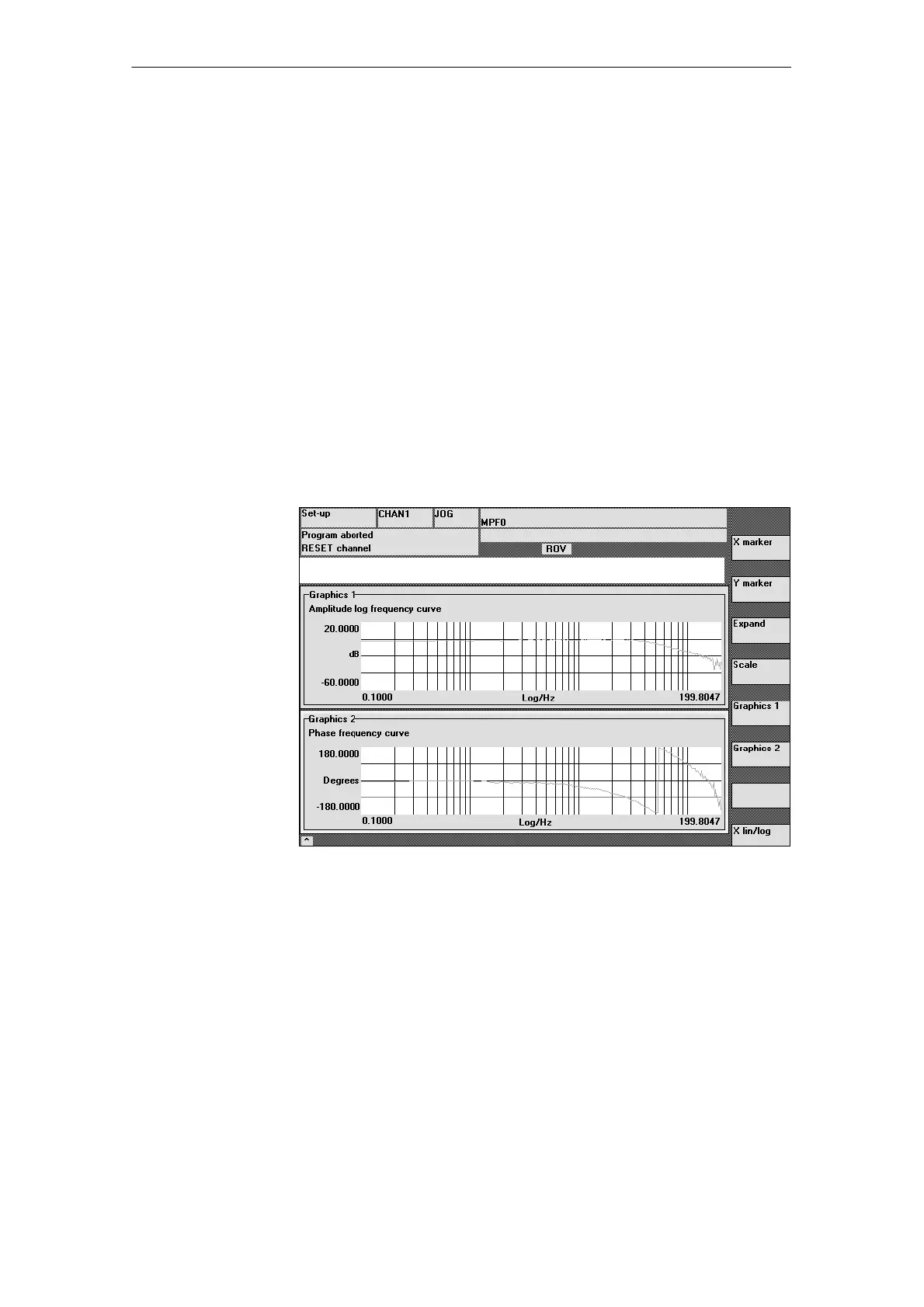

Fig. 10-4 Display diagram: Example of a position control loop

The reference frequency response measurement determines the transmission

response of the position controller in the frequency range (active position mea-

suring system). The parameters for the setpoint filters, K

v

value and bias control

should be set to ensure there is as little resonance as possible throughout the

frequency range. In the case of dips in the frequency response, the setting of

the feedforward control balancing filters should be checked. Excessive reso-

nance requires

1. Decrease in K

V

value

2. Canceling the bias control value

3. Use of setpoint filters

The effects of these measures can also be checked in the time range.

Functionality

Procedure

Reference

frequency

response

10 Drive O

timization

Loading...

Loading...