6 Pro

rammin

the control

6

03/2006

6.9 Axes and spindles

6-89

© Siemens AG 2006 All Rights Reserved

SINUMERIK 840D/810D Start-Up Guide (IADC) – 03/2006 Edition

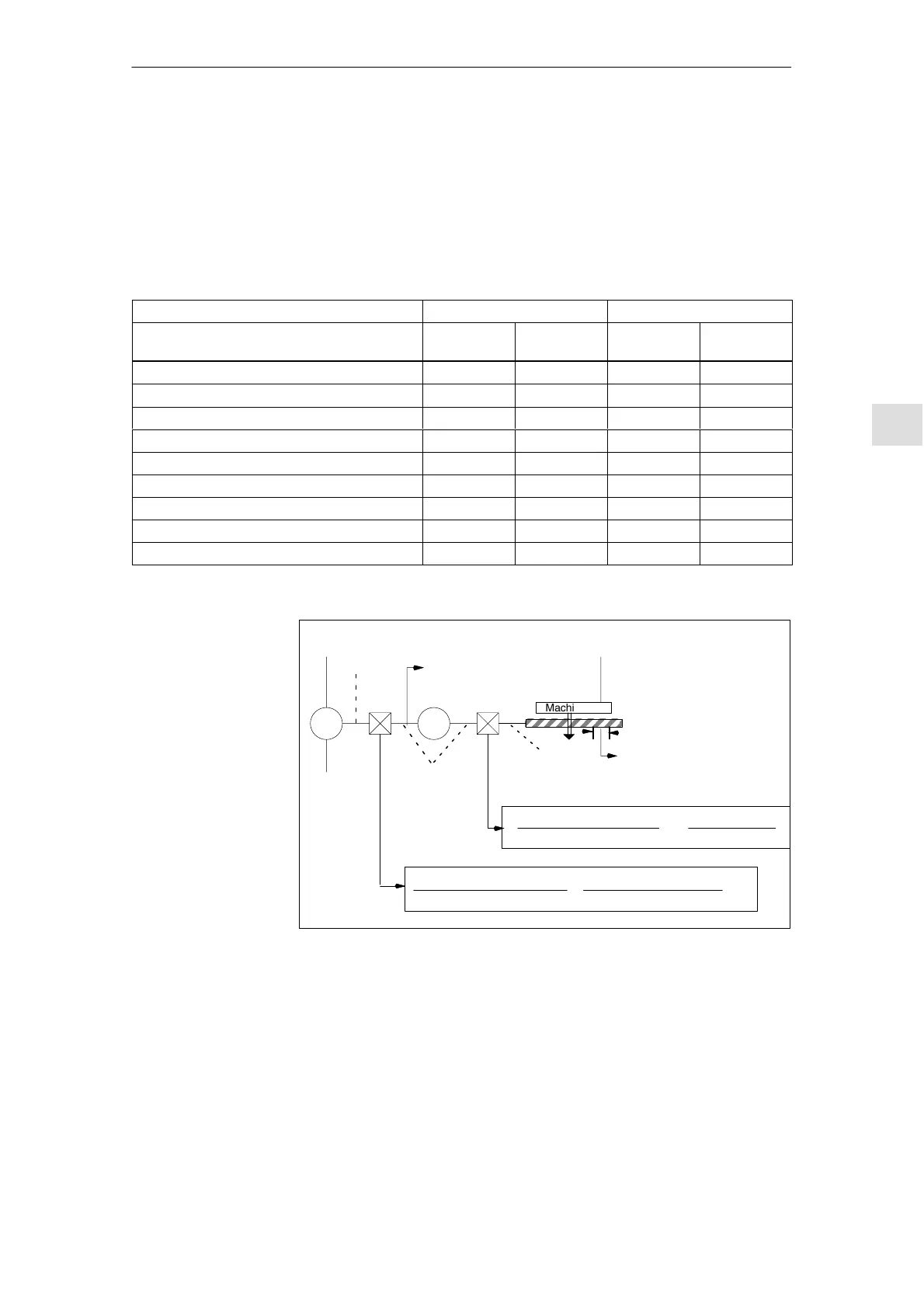

6.9.5 Parameter settings for incremental measuring systems

The following table lists all the parameters which have to be entered for encoder

adjustment.

Table 6-16 Machine data for matching rotary encoders

Machine data Linear axis Rotary axis

Encoder on

motor

Encoder on

machine

Encoder on

motor

Encoder on

machine

30300: IS_ROT_AX 0 0 1 1

31000: ENC_IS_LINEAR 0 0 0 0

31040: ENC_IS_DIRECT 0 1 0 1

31020: ENC_RESOL Marks/rev Marks/rev Marks/rev Marks/rev

31030: LEADSCREW_PITCH mm/rev mm/rev – –

31080: DRIVE_ENC_RATIO_NUMERA Motor rev. Load rev. Motor rev. Load rev.

31070: DRIVE_ENC_RATIO_DENOM Encoder rev. Encoder rev. Encoder rev. Encoder rev.

31060: DRIVE_AX_RATIO_NUMERA Motor rev. Motor rev. Motor rev. Motor rev.

31050: DRIVE_AX_RATIO_DENOM Spindle rev. Spindle rev. Load rev. Load rev.

M

IS_ROT_AX=0

Machine table

ENC_IS_LINEAR=0

ENC_RESOL

G

DRIVE_AX_RATIO_NUMERA No. of motor rev.

DRIVE_AX_RATIO_DENOM

=

No. of spindle rev.

ENC_IS_DIRECT=0

LEADSCREW_PITCH

n

Encoder

Resolver

gearbox

n

Motor

Load

gearbox

n

Spindle

Leadscrew

DRIVE_ENC_RATIO_NUMERA

DRIVE_ENC_RATIO_DENOM

+

Numberofmotorrevolutions

Numberofencoderrevolutions

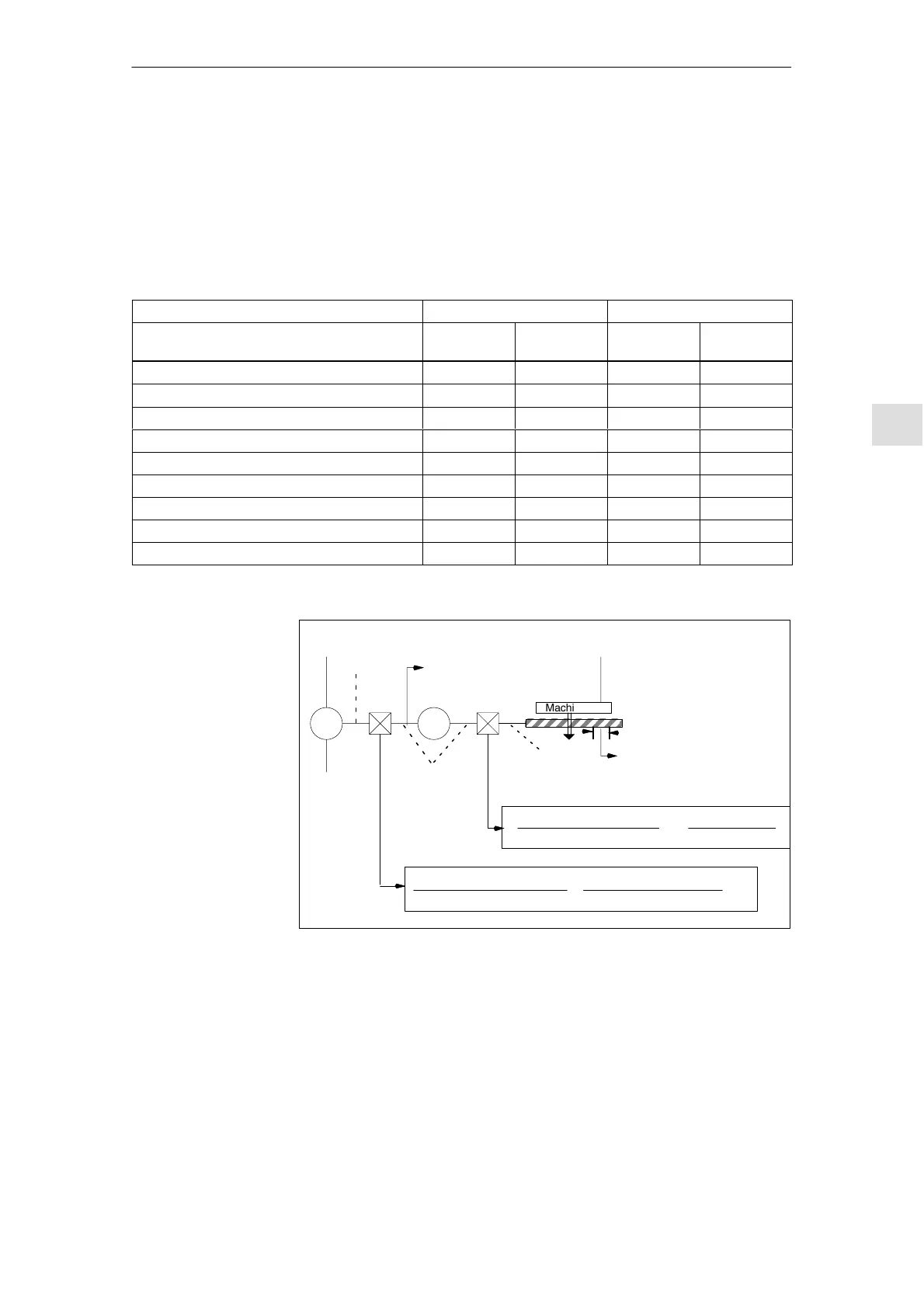

Fig. 6-8 Linear axis with motor-mounted rotary encoder

Rotary encoders

Linear axis with

rotary encoder at

the motor

Loading...

Loading...