6 Pro

rammin

the control

6

03/2006

6.10 Linear motors (1FN1 and 1FN3 motors)

6-137

© Siemens AG 2006 All Rights Reserved

SINUMERIK 840D/810D Start-Up Guide (IADC) – 03/2006 Edition

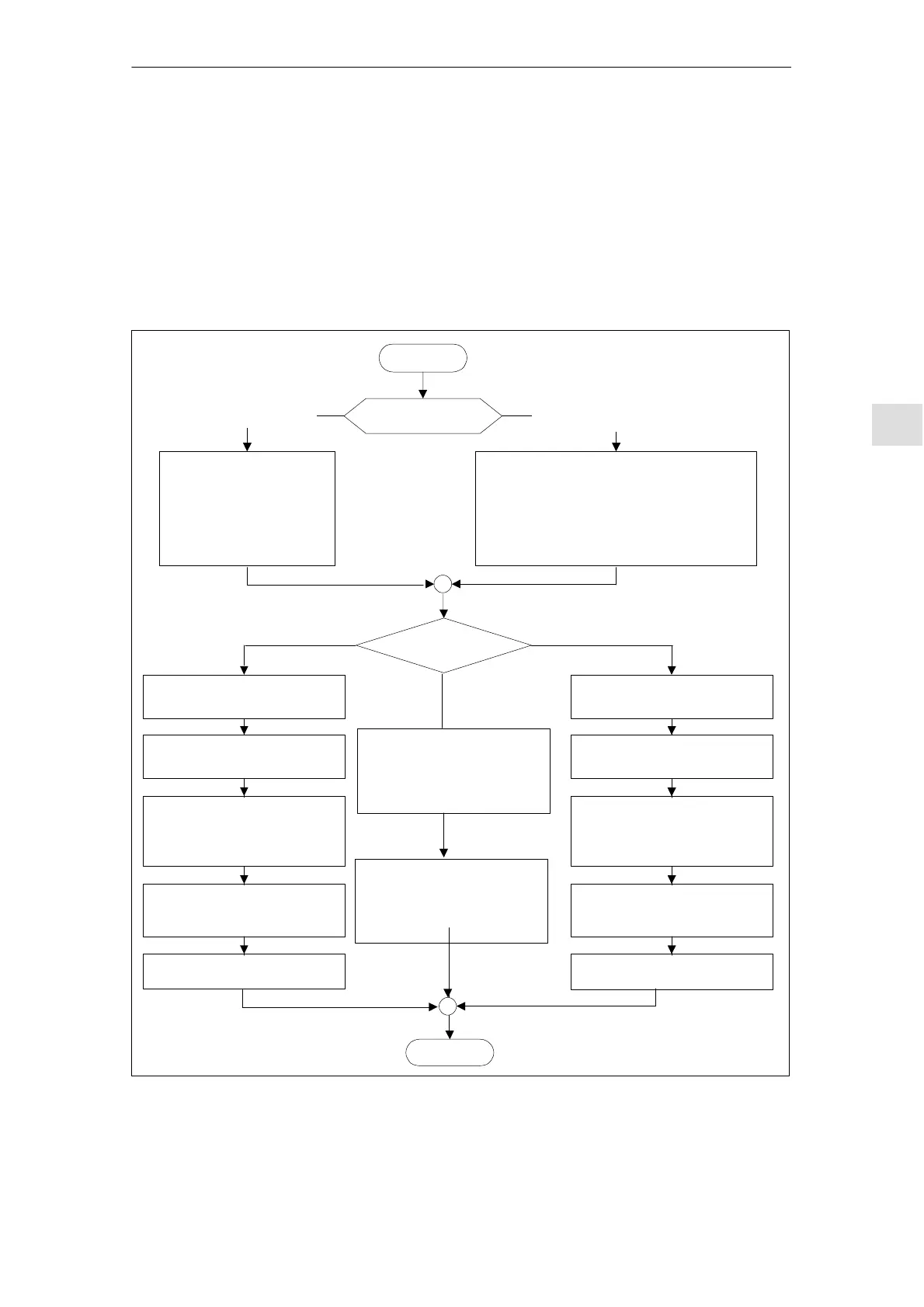

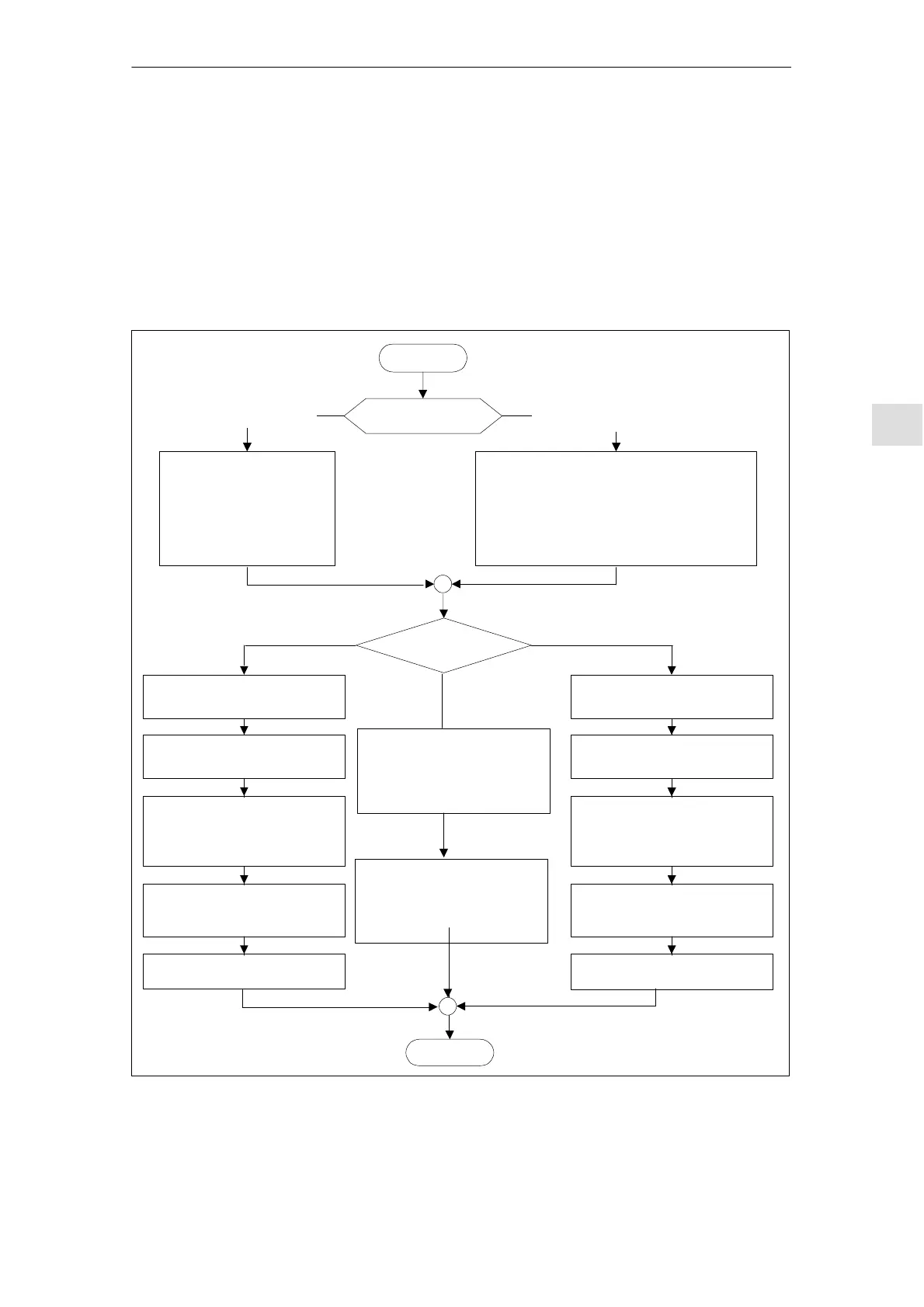

7. Determine the commutation angle offset

The commutation angle offset is determined as follows:

a) Select identification method via MD 1075. Possibly adapt other

machine data for rotor position identification.

b) Save the boot files and perform NCK reset.

c) Depending on which measuring system is used, continue as follows:

With an incremental measuring system:

Zero markers?

End

START

The coarse synchroniza-

tion is obtained from the

Hall sensor signals (C/D

track) on switching on

Several zero markers with cams

or distance-coded reference

markers from VSA 06.07.07

No zero marker, several zero mar-

kers without cam distance-coded

reference markers from up to VSA

06.07.07

There is no selection of the zero

marker and the commutation angle

offset is not accepted

Reference axis on the NCK side

Yes, Hall sensor

boxes present

No, Hall sensor boxes

not present

If the enables are set, a rotor position identification

is carried out immediately.If the rotor position identi-

fication is unsuccessful, the appropriate error mes-

sage is output. Once the causes of the fault have

been eliminated and the error message acknowled-

ged, another attempt at identification is made.

Are Hall sensor

boxes present?

Set MD 1017 (”Start-up help”) to 1

Set MD 1017 (”Start-up help”) to 1

Move axis over the zero marker,

“JOG” operating mode

When it moves over the zero mar-

ker, the commutation angle offset

is entered in MD 1016

One zero marker

When it moves over the zero mar-

ker, the commutation angle offset

is entered in MD 1016

Alarm 300799 appears (”Save boot

files and perform NCK reset”)

Alarm 300799 appears (”Save boot

files and perform NCK reset”)

Save boot files and perform

NCK reset

Save boot files and perform

NCK reset

Fig. 6-31 Incremental measuring system

Incremental

measuring system

Loading...

Loading...