Hardware and Connections

2-177SA6 Manual

C53000-G1176-C133-1

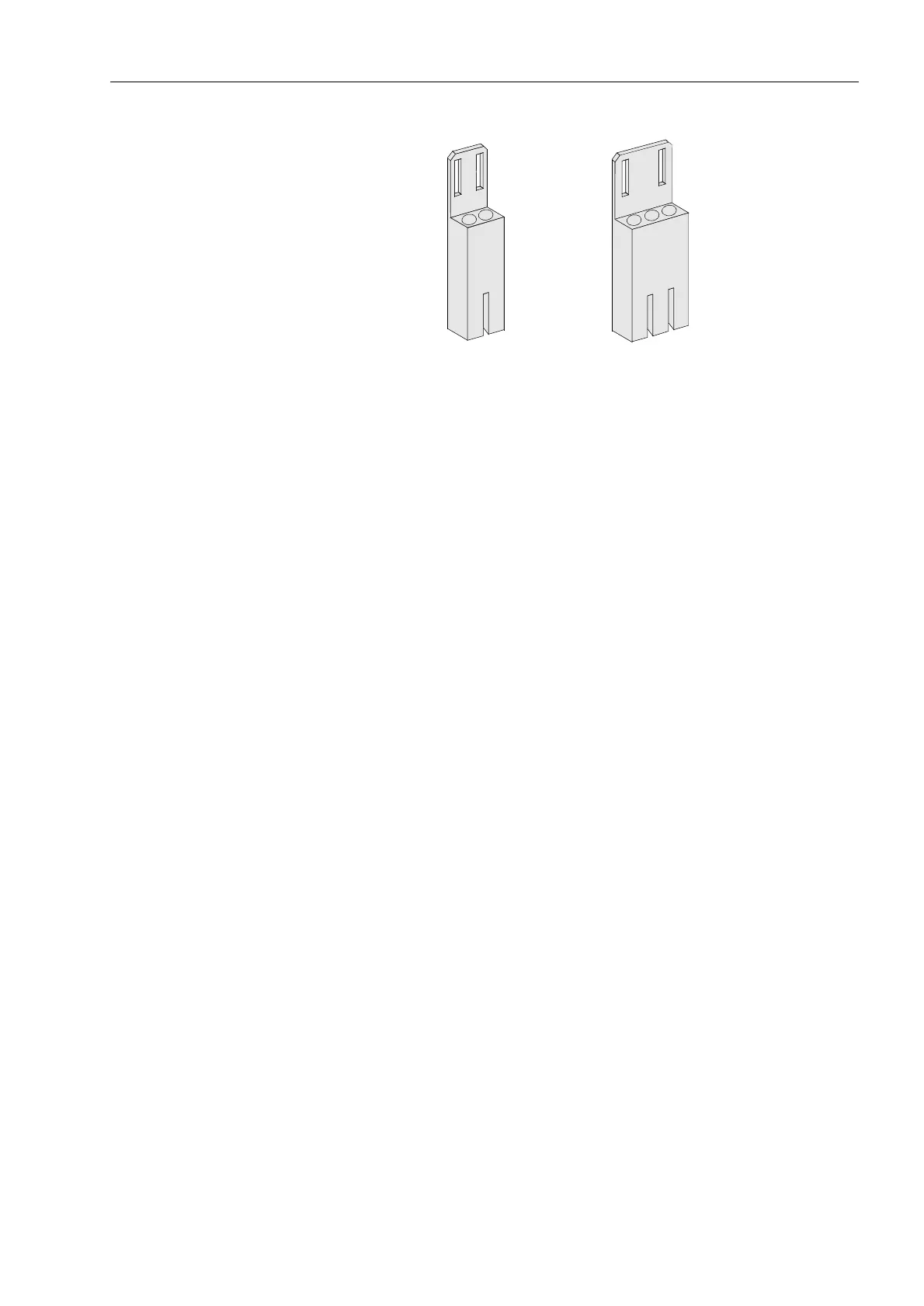

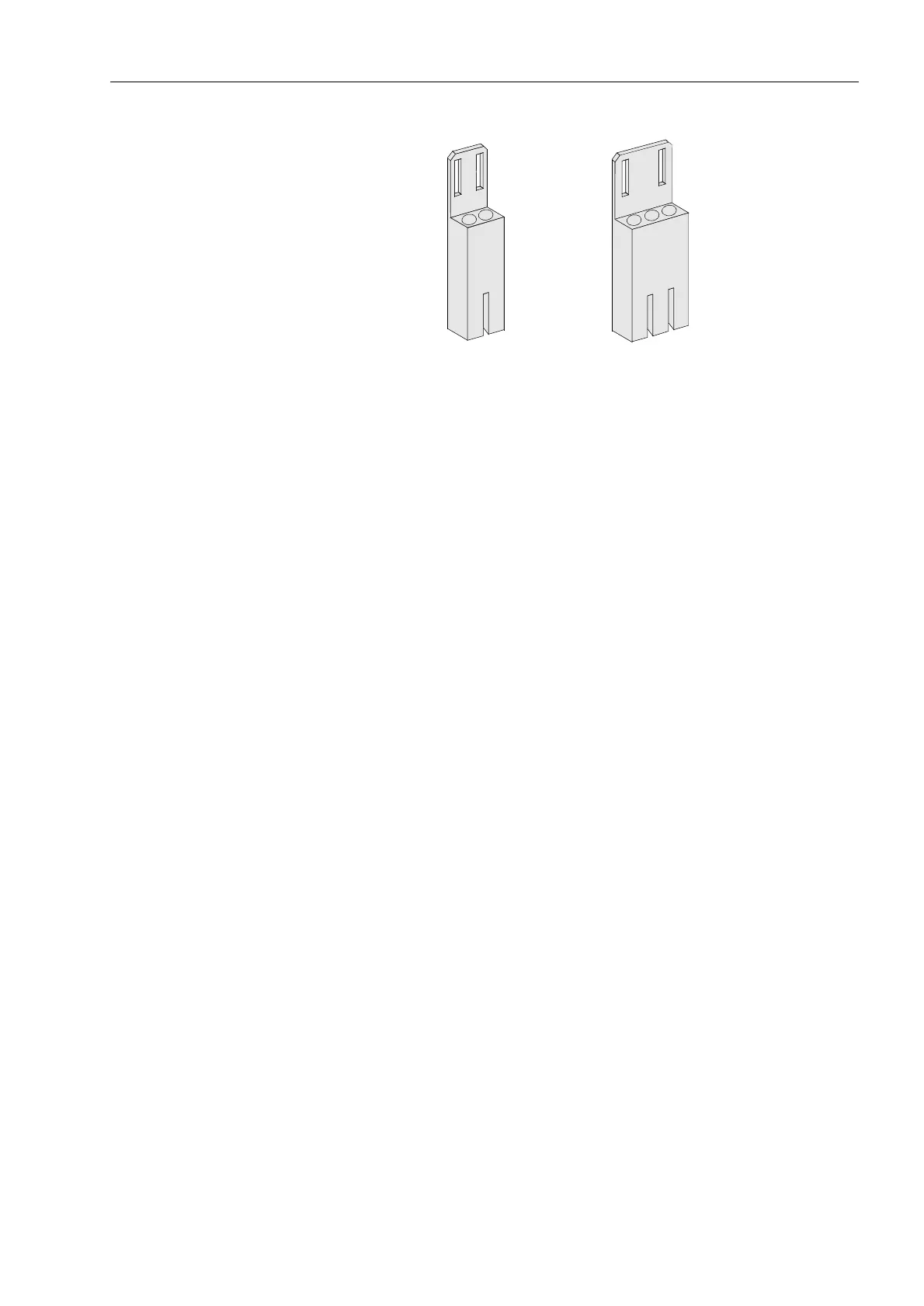

Figure 2-17 2-pin connector and 3-pin connector

Ordering information for the pin connectors is provided in Section 1.1 of Appendix A.

The design of the pin connectors is such that only correct connections can be made.

For example, the design of the 2-pin connector allows connection only to pins “a” and

“b”. An erroneous connection to pins “b” and “c” is excluded due to the construction of

the pin connectors.

The pin connectors snap in to the plug-in terminals. The connectors can be removed

without tools.

Control wires are connected to contacts of the pin connectors. Wires with 0.5 mm

2

to

2.5 mm

2

diameter (AWG 20 to 14) can be accommodated.

Use only flexible copper control wire!

The crimp connector required depends on the diameter of the conductor being used.

Section 0.5 mm

2

to 1.0 mm

2

:

e.g. Bandware 4000 pieces type: 0-827039–1 from AMP Corp.

Individual piece type:0- 827396–1 from AMP Corp.

Section 1.0 mm

2

to 2.5 mm

2

:

e.g. Bandware 4000 pieces type: 0-827040–1 from AMP Corp.

Individual piece type: 0-827397–1 from AMP Corp.

Connection of a conductor to a contact is performed using,

e.g., a hand crimping tool type 0–734372-1 from AMP Corp.

matrix type 1-734387-1 from AMP Corp.

Individual pieces are recommended.

The gold-plated connector (recommended) depends on the diameter of the conductor

that is used.

Section 0.75 mm

2

to 1.5 mm

2

:

e.g. Bandware 4000 pieces type: 163083-7 from AMP Corp.

Individual piece type: 163084-7 from AMP Corp.

Connection of a conductor to a contact is performed using a hand crimping tool,

e.g. a hand crimping tool type: 0-539635–1 from AMP Corp.

matrix type: 0-539668–2 from AMP Corp.

Individual pieces are recommended.

a

b

a

b

c

Loading...

Loading...