Maintenance and servicing

6.4 Replacing components

Cabinet Modules NEMA

Manual, 04/2014, A5E03586450A

295

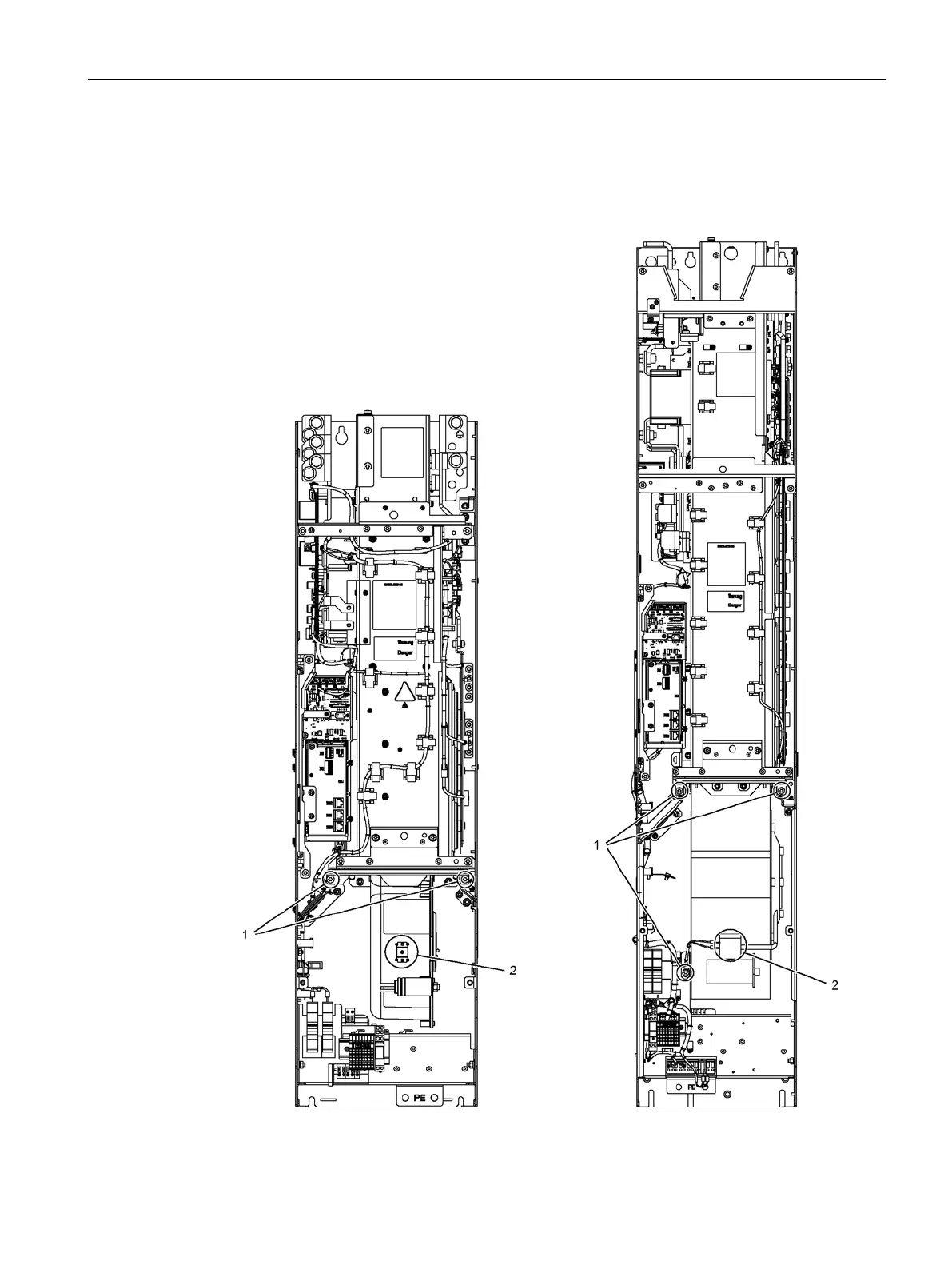

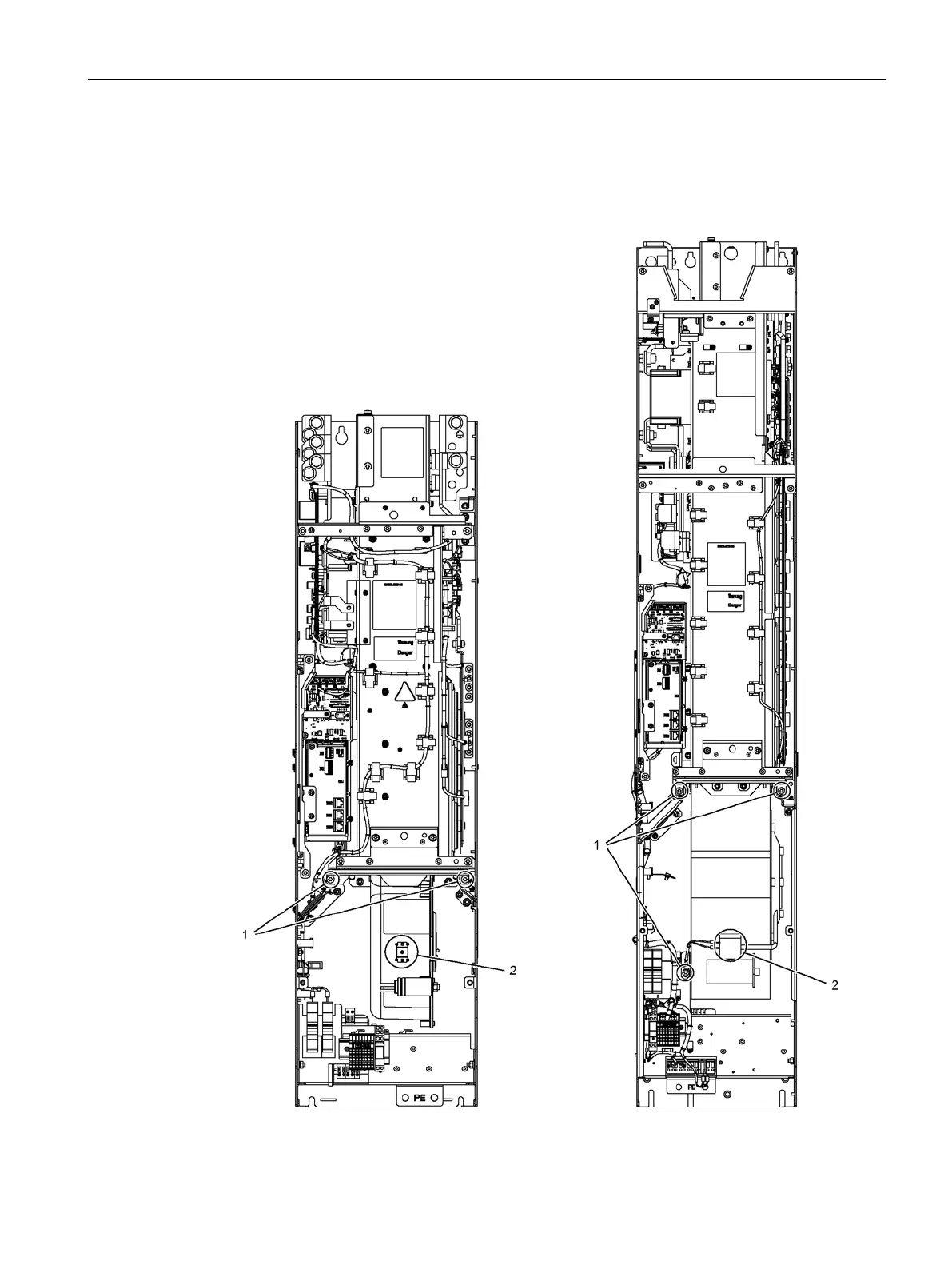

Replacing the fan, frame sizes FB, GB and GD

Replacing the fan

Figure 6-17 Replacing the fan, Basic Line Module, frame sizes FB, GB, and GD

Loading...

Loading...