6-29

IM 05P01C31-01EN

MonitoringandControlofRegularOperations

6

Manual PID Tuning Procedure

(1) In principle, auto-tuning must be used.

(2) TunePIDparametersintheorderofP,I,andD.Adjustanumericslowlyby

observing the result, and keep notes of what the progress is.

(3) Graduallyreduce

Pfromalargervalue.WhenthePVvaluebeginstooscillate,stop

tuning and increase the value somewhat.

(4) Alsog

raduallyreduceIfromalargervalue.WhenthePVvaluebeginstooscillate(with

long period), stop tuning and increase the value somewhat.

(5) Grad

uallyincreaseDfromasmallervalue.WhenthePVvaluebeginstooscillate(with

short period), stop tuning and lower the value slightly.

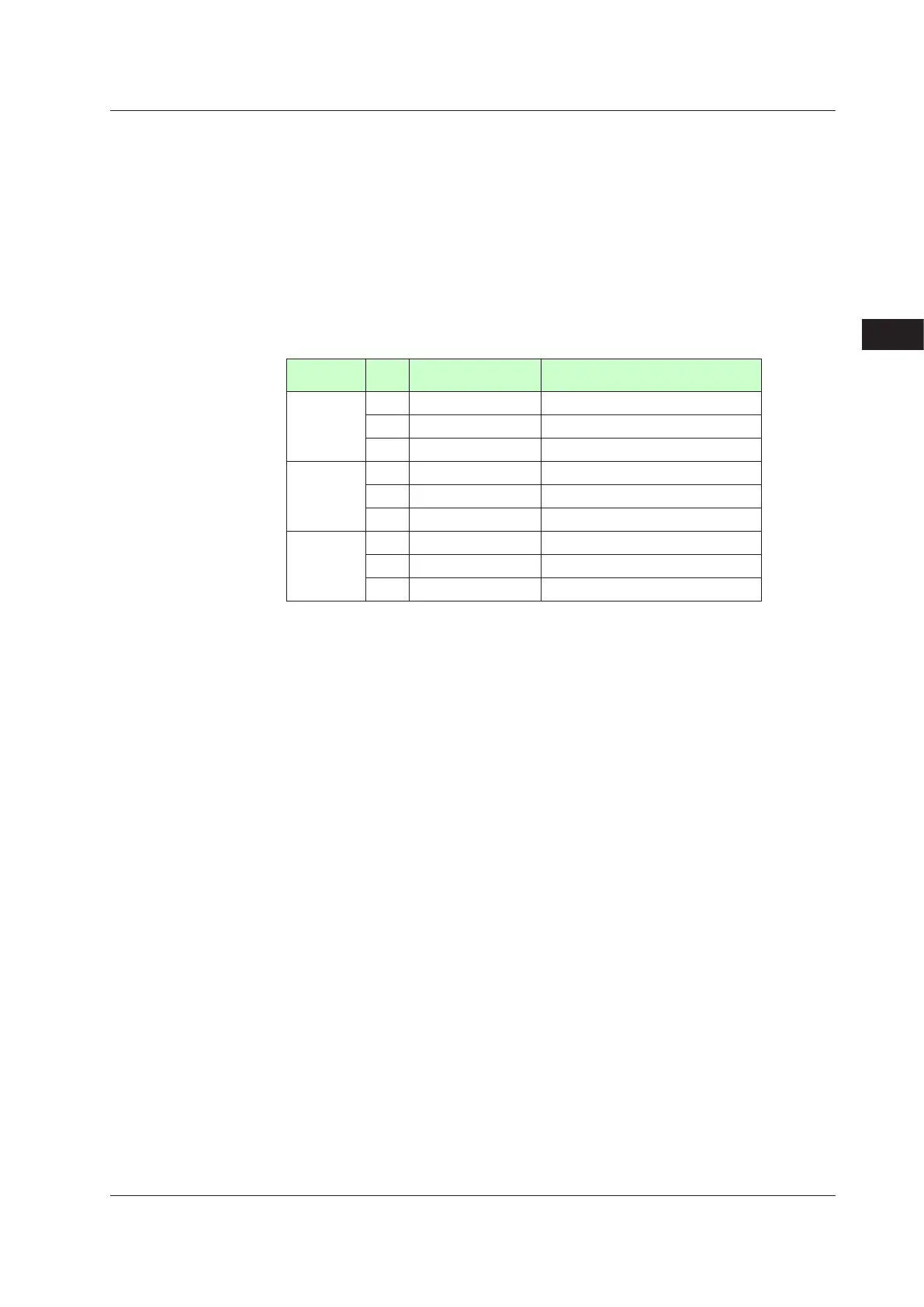

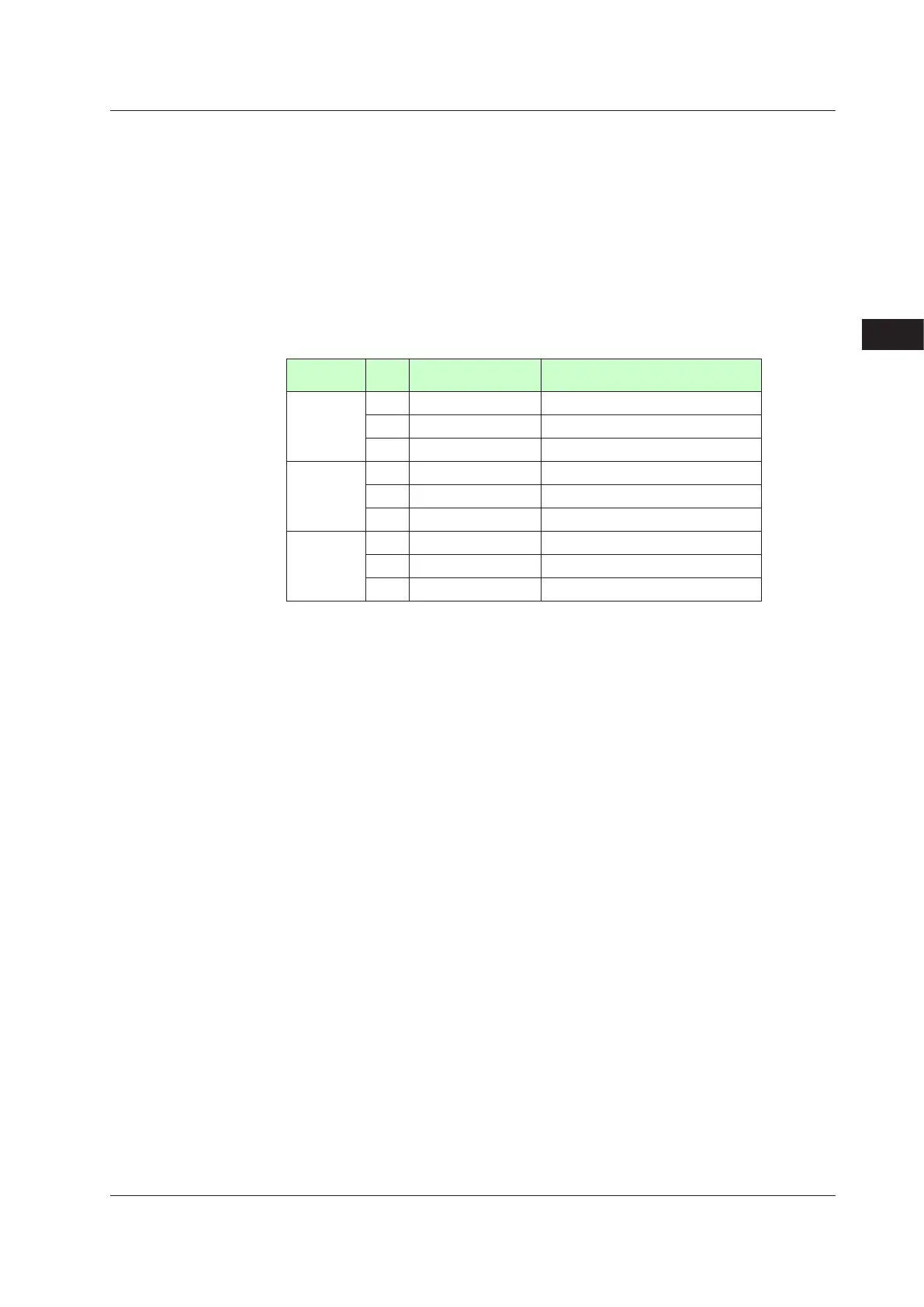

ReferenceValues

forManualTuningofTemperature,Pressure,andFlowRate

Setting range

(reference)

Initialvaluefortuning(reference)

Pressure

P 100to300% 200%

I 5 to 30 s 15 s

D OFF OFF

Flow rate

P 100

to240% 150%

I 8 to 30 s 20 s

D OFF OFF

Temperature

(electric

furnace)

P 1to20% 5%

I

180 to 600 s 240 s

D 1/4 to 1/6 of I 60 s

6.4AdjustingPIDManually

Loading...

Loading...