116 | PGC5000 GEN 2 | 892 J006 MNAH

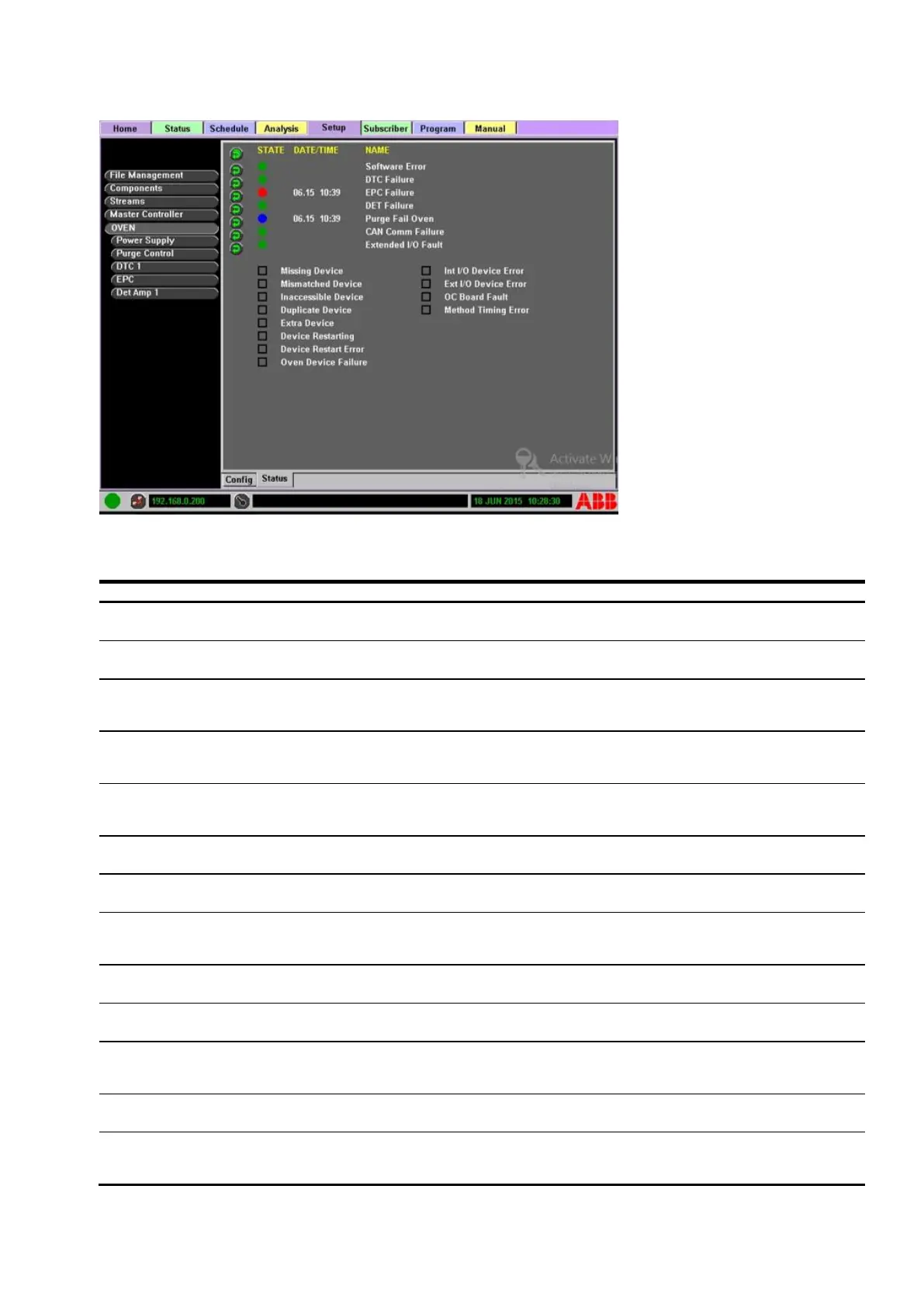

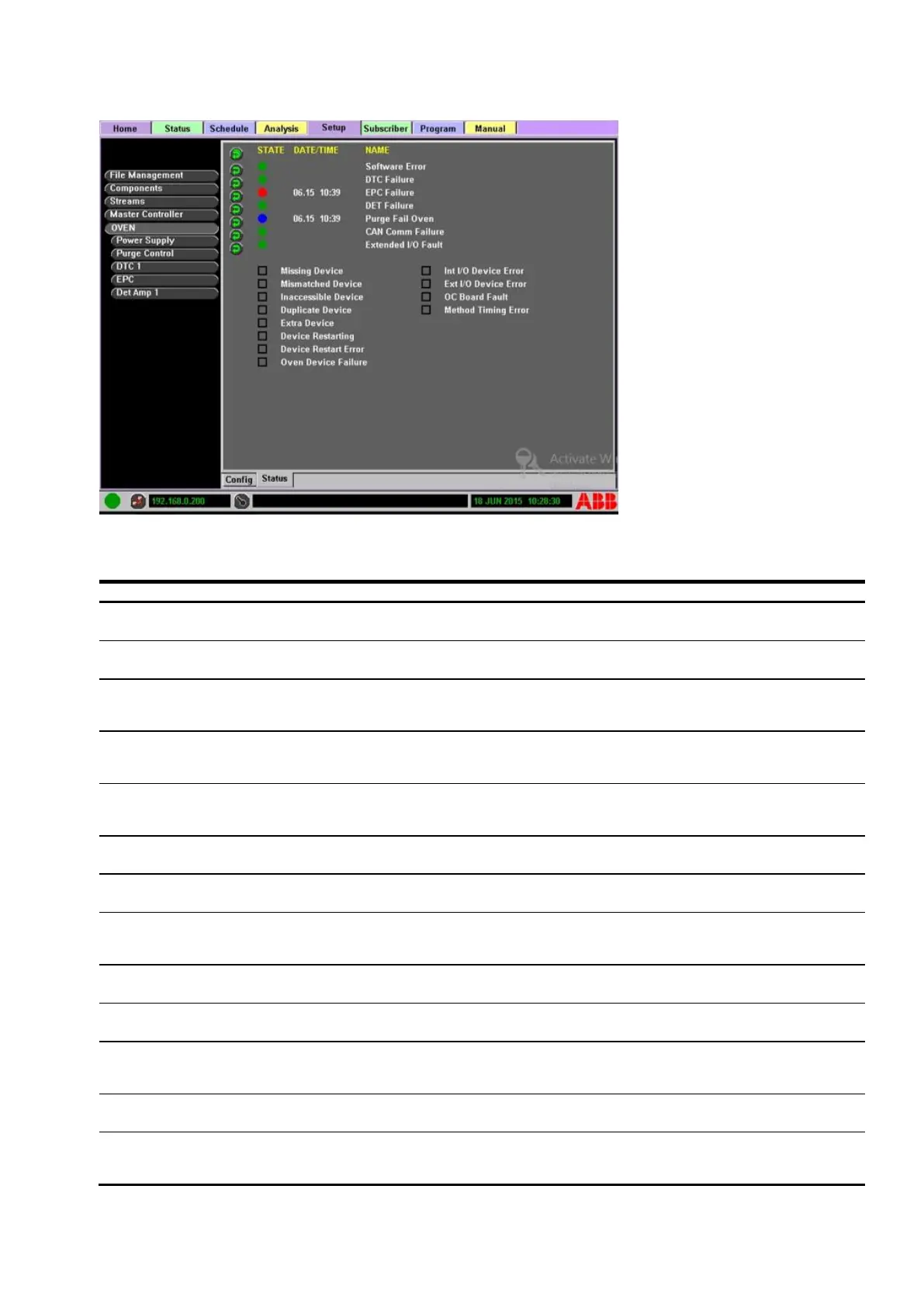

Figure 6-3: Diagnostic display example

The following table gives a resolution to indicator boxes where applicable.

Table 6-3: Box indicator descriptions

Board did not report to Oven

Controller (OC) at startup.

Check power to board. Check CAN

connections. Contact ABB.

Board identity does not match

config file.

Contact ABB. Check config file.

Board communication not

viable.

Check CAN connection to Wago

module.

Refer to Wago documentation.

Two devices have the same

CAN node ID.

Correct by changing the node ID of

one of the duplicate boards. Refer to

the Service Manual.

A board that responded to the

OC is not listed in the system

configuration.

Contact ABB for more information.

Remove board.

PIC Comm Error

(Hardware Error)

DSP and PIC supervisor have

stopped communicating.

Replace DTC Digital card. Refer to the

Service Manual.

Broken valve

(Hardware Error)

Valve failed start-up test.

Check solenoid block cable. Replace

faulty solenoid if problem persists.

AC fault (Hardware

Error)

DTC did not detect AC or

power to heater failed.

Check AC connections to DTC

assembly. T-Rating faults can also

cause this symptom.

Current out-of-range

(Hardware Error)

Internal power test failed.

Check heater(s) to verify proper

resistance. Check heater connections.

Device did not communicate

with OC or go online.

Check board LEDs for error. Refer to

the Service Manual.

Device stopped

communicating.

Check board LEDs for error. Check

CAN bus.

Refer to the Service Manual.

Failed to send executable code

to device.

Check board LEDs for error. Refer to

the Service Manual.

Unexpected Heater

Voltage

Internal power test failed.

Can occur as a result of PIC

supervisor shutdown or T-Rating

failure. Verify heaters and

Loading...

Loading...