138 | PGC5000 GEN 2 | 892 J006 MNAH

17. Go to Setup>Master Controller>SBC>Network Adapters and enter the analyzer NAME in

the HOST NAME field exactly as it appeared on the Master Controller screen.

18. Click Network Save (Disk Icon above the HOST NAME caption). All configuration and network

information will be refreshed and the system will reboot.

19. At this point the upgrade is complete.

To repeat the process, remove all the files from the recovery drive and remove the Configuration

folder from the upgrade drive.

9 Temperature programmed oven

9.1 General description

The Temperature Programmed Gas Chromatograph (TPGC) analyzes samples with wide variations in

component boiling points or molecular weights. It operates the same as the standard PGC5000

Generation 2 Process GC described in the previous sections of these Operating Instructions. It differs

from the standard GC in having a temperature programmed oven (TPO) contained within the

isothermal oven, and in how some operating features are utilized.

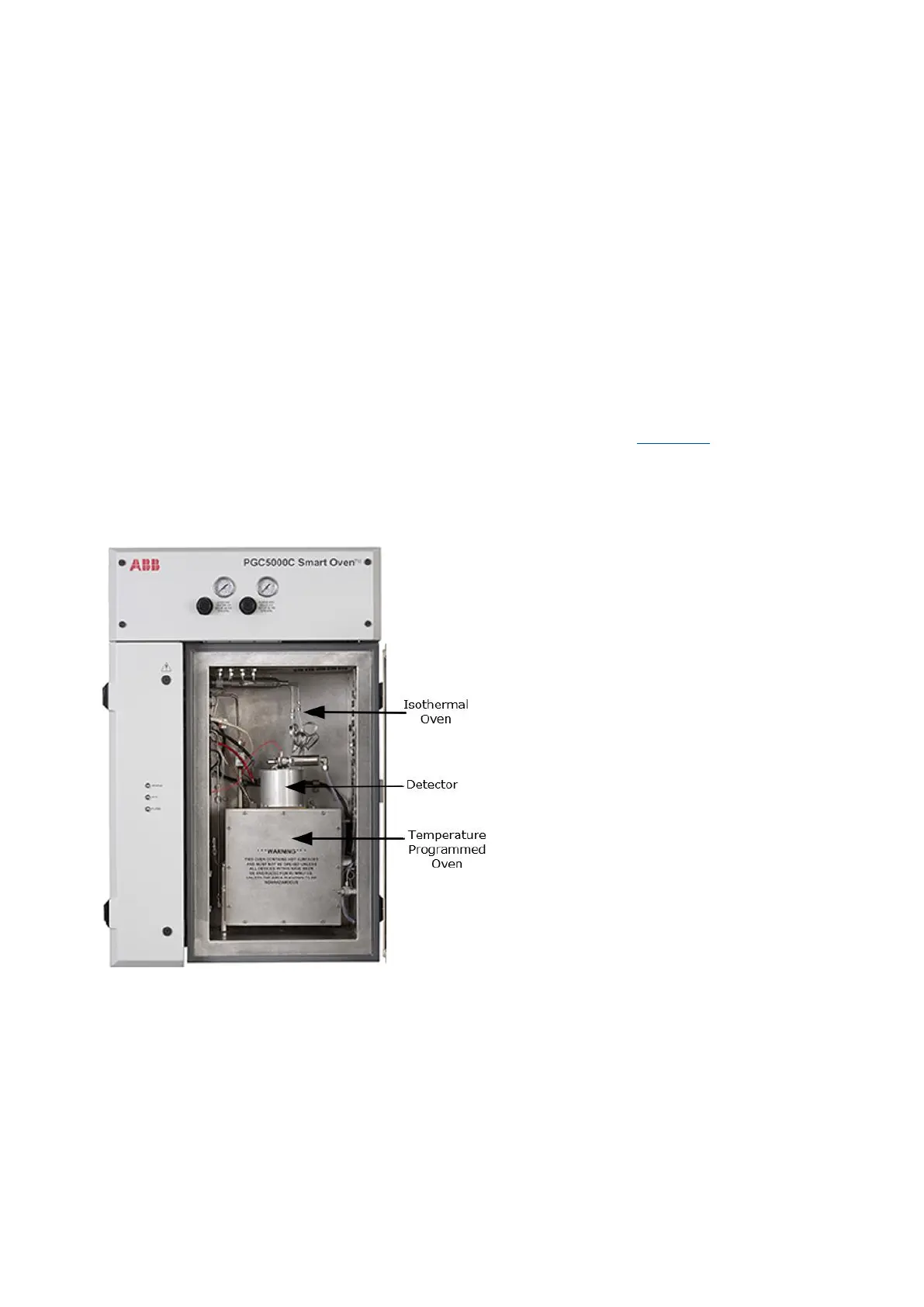

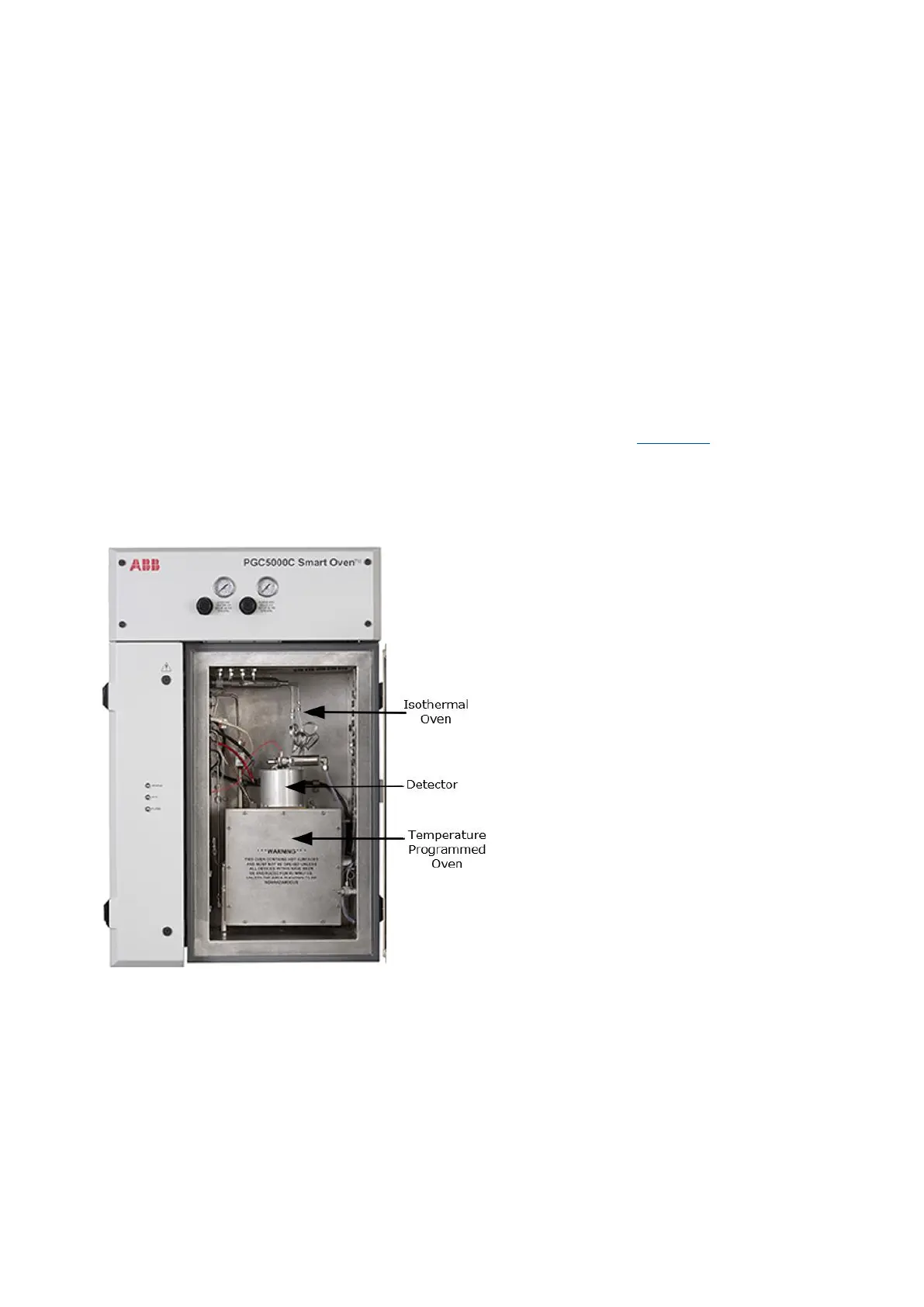

From the outside, the Oven Compartment looks the same as that of the standard PGC5000 Generation

2 C-Class oven. Internally, however, the TPO compartment is different (see Figure 9-1) in that the

TPO contains:

⎯ isothermal oven

⎯ detector (FID or TCD)

⎯ an insulated, temperature programmed oven containing the analytical column

Figure 9-1: Oven Compartment

9.1.1 Master Controller

Since the Master Controller for the Temperature Programmed GC is identical to the PGC5000

Generation 2 Master Controller, the information regarding the Master Controller in the relevant

sections of the PGC5000 Generation 2 Operating Instructions and Service Instructions is all applicable.

9.1.2 Isothermal oven

The isothermal oven contains the liquid sample valve, detector, and digital temperature controller,

which are the same as those in the standard GC. An optional Air Cleanup/ Methanizer Unit may be

used. In addition, the isothermal oven contains the temperature programmed (TP) oven.

Loading...

Loading...