16 | PGC5000 GEN 2 | 892 J006 MNAH

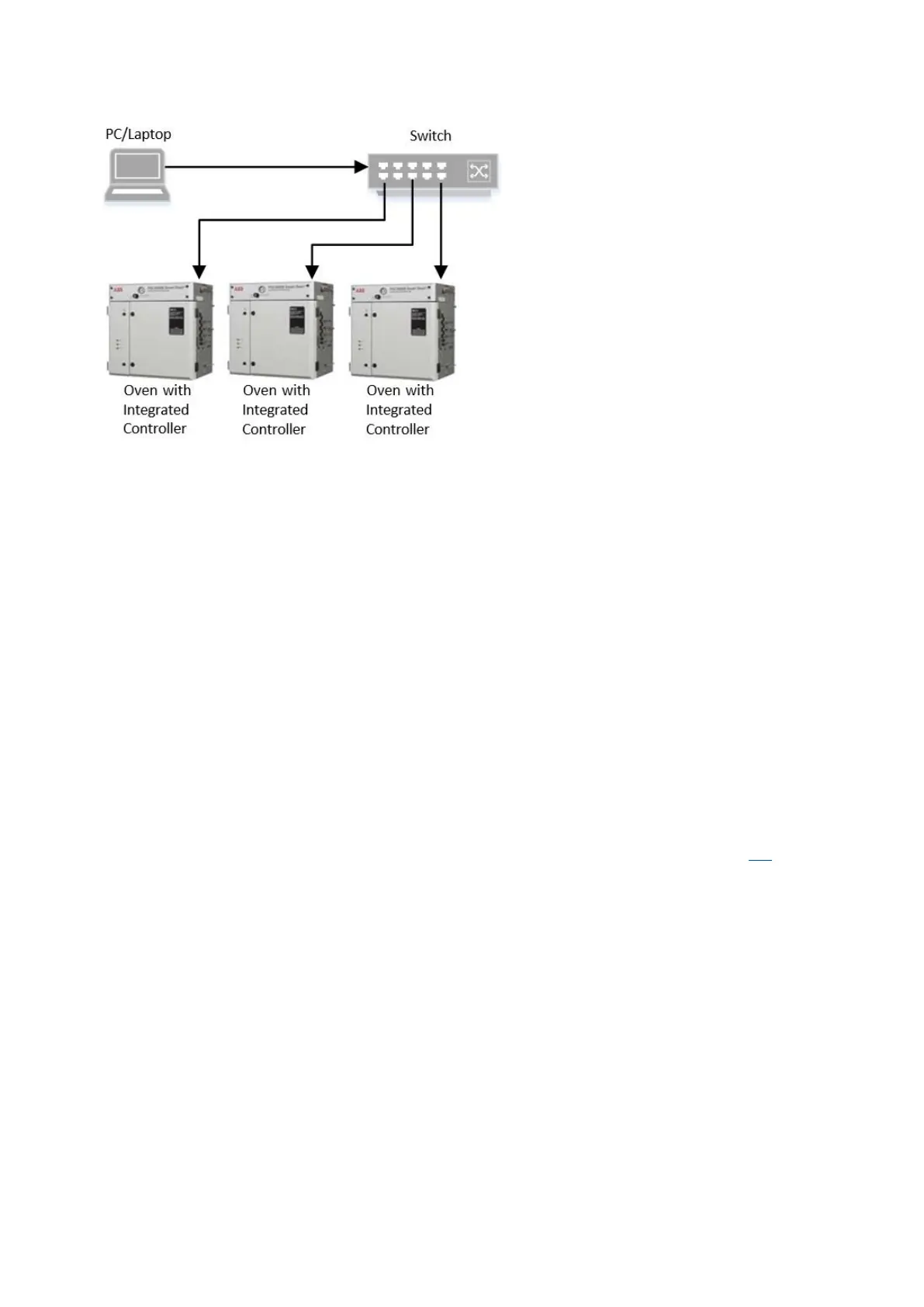

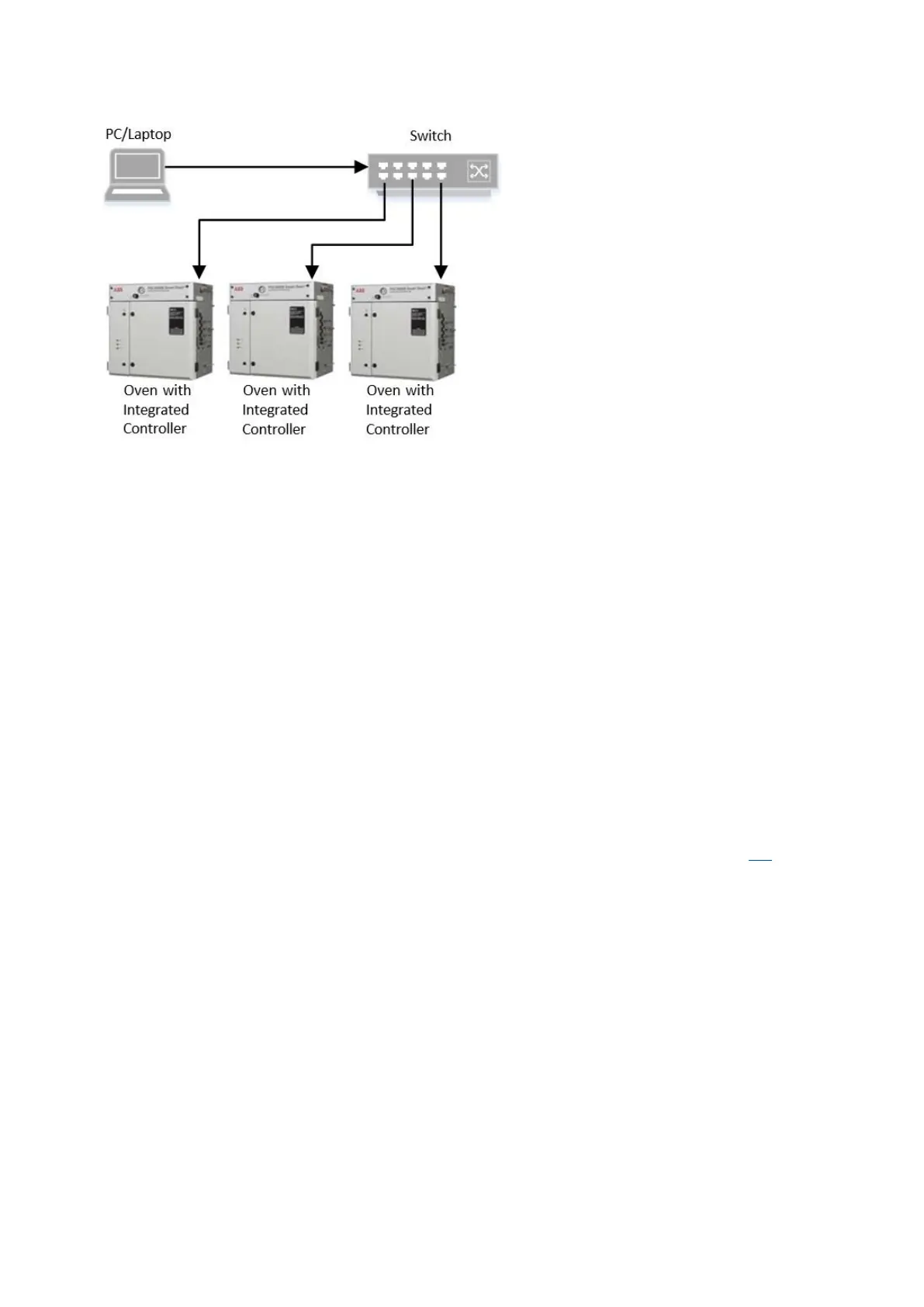

Figure 1-2: Oven with integrated controller connections

1.1 Data Package

All important documents for the sales order are saved in a folder on a SharePoint site using a custom

shared link. Included in the sales order documents are the drawings, manuals, replacement parts list

and test data needed to support installation and operation of the analyzer(s). This manual refers to

these resources as the “Data Package.”

1.2 Drawings

Since analyzer configuration depends on the application, this manual does not contain generic

engineering drawings and diagrams. Utilize the drawings, diagrams and replacement parts lists

provided in the Data Package for your analyzer to ensure you are using the correct ones for your

system.

1.3 Master controller

The Master Controller can support up to four ovens in any combination of Class B and Class C ovens,

depending on detector configurations. If internal I/O modules are utilized, the maximum number of

ovens per Master Controller is three.

The Master Controller contains a Mounting Plate with a Single Board Computer (SBC) PCB, a Power

Supply, one or more SBC CAN Interface Cards, and optional Wago input/output modules. The front

panel assembly has a touchscreen, liquid crystal display (LCD), keypad, and front panel board.

No Master Controller is required for the Oven with Integrated Controller. The Oven with Integrated

Controller can support up to four ovens in any combination of Class B and Class C Ovens, depending

on detector configurations. The user interface is accessed remotely, as described in Section 3.7.

The PGC5000 Generation 2 Master Controller can also act as a stand-alone RUI. In this configuration,

the Master controller will not be connected to an oven, and it will not contain SBC CAN Interface Cards

or Wago input/output modules. It will be connected to the analyzer network via Ethernet and can

connect to any PGC5000 Generation 2 device that is supported.

1.4 Class B oven

The Class B oven, which comes in liquid and vapor versions, houses an isothermal oven which

contains the analytical columns, detector, detector amplifier, temperature controller, control valves,

and sample valve. The Class B oven has one detector and a maximum of four valves.

1.4.1 Liquid version

The liquid version incorporates a liquid sample valve (LSV) as the input to the analysis. The duration

of an analysis depends on the application and consists of the following:

⎯ The liquid sample valve injects a fixed volume of sample into a vaporizing chamber.

⎯ “Sweep gas” transports the sample out of the vaporizing chamber.

⎯ Carrier transports the vaporized sample into the column.

⎯ The column then separates the components and passes them into the detector.

⎯ The detector measures the sample across the range of high to low concentration.

Loading...

Loading...