MODULE 11: COMPONENT REPLACEMENT AND TROUBLESHOOTING

11-16 AEROSET

®

Customer Training Guide

94858-103 — July 2003

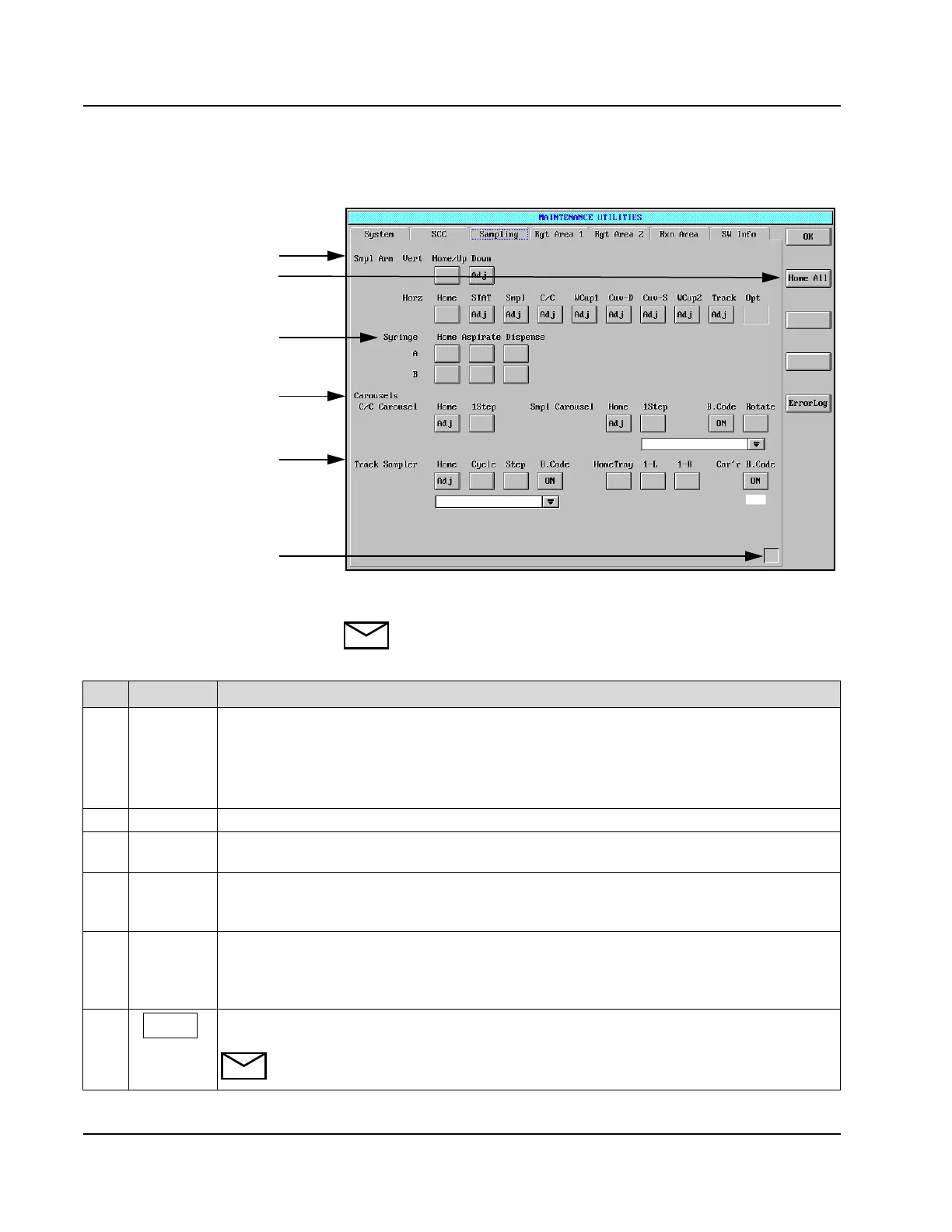

Sampling Page

Figure 11.10: MAINTENANCE UTILITIES Screen, Sampling Page

NOTE: Ensure each component is in the home position before

movement or adjustment.

Item Field Allows the Operator to…

1

Smpl

(Sample)

Arm

Move the Sample Arm horizontally or vertically. The horizontal control allows the Sample Arm to

move to the following positions:

Home, STAT, Smpl (Sample Carousel),

C/C (Calibrator/Control Carousel), Wash Cups 1 and 2, Cuv-D (diluted sample), Cuv-S

(sample), Track (FastTrack™) and Opt (External Robotics).

2

<Home All> Home all robotics.

3

Syringe Move the Sample Syringe drive. The Operator may also request the syringe drives to home,

aspirate, or dispense.

4

Carousels Move the Calibrator/Control and Sample Carousels. The Operator may also turn the Bar Code

Reader ON and rotate the Sample Carousel to read the bar code labels on the samples loaded in

the carousel.

5

Track

Sampler

Move the FastTrack Sampler. The Operator may turn ON the Sample ID Bar Code Reader and

read the bar codes on the samples loaded on the Sample Carrier using the Cycle button. The Car’r

(Carrier) Bar Code Reader may also be activated. Lastly, if a Sample Carrier Tray is loaded, the

Operator may home the tray or move it left (1-L) or right (1-R).

6

This area displays a blue triangle when the System is busy. A green square displays when the status

is READY.

NOTE: When the System is busy, no further commands are acknowledged until the

original command is completed.

• Carousels — if

doesn’t see bar

code, gets a line.

• If button has the

word “adj”, when

touched, the word

“adj” will pop-up

on the button on

the right.

•If “adj” is touched,

will get pop-up

“CW” = clockwise,

or “CCW” =

counterclockwise.

(or up and down)

1

3

4

5

6

2

Loading...

Loading...