68 1100 Series Nano Pump Service Manual

2 Troubleshooting and Test Functions

Normal Mode Pressure Test

Description

The pressure test is a quick, built-in test designed to demonstrate the

pressure-tightness of the system. The test should be used when problems with

leaks are suspected, or after maintenance of flow-path components (e.g.,

pump seals, injection seal) to prove tightness up to 400 bar. The test involves

monitoring the pressure profile as the nano pump runs through a predefined

pumping sequence. The resulting pressure profile provides information about

the pressure tightness of the system.

The injection device outlet (port 6) is blocked with a blank nut, and then the

test is run using isopropyl alcohol (IPA), while monitoring the pressure profile

(using an integrator on the analog output, or in the plot screen in the

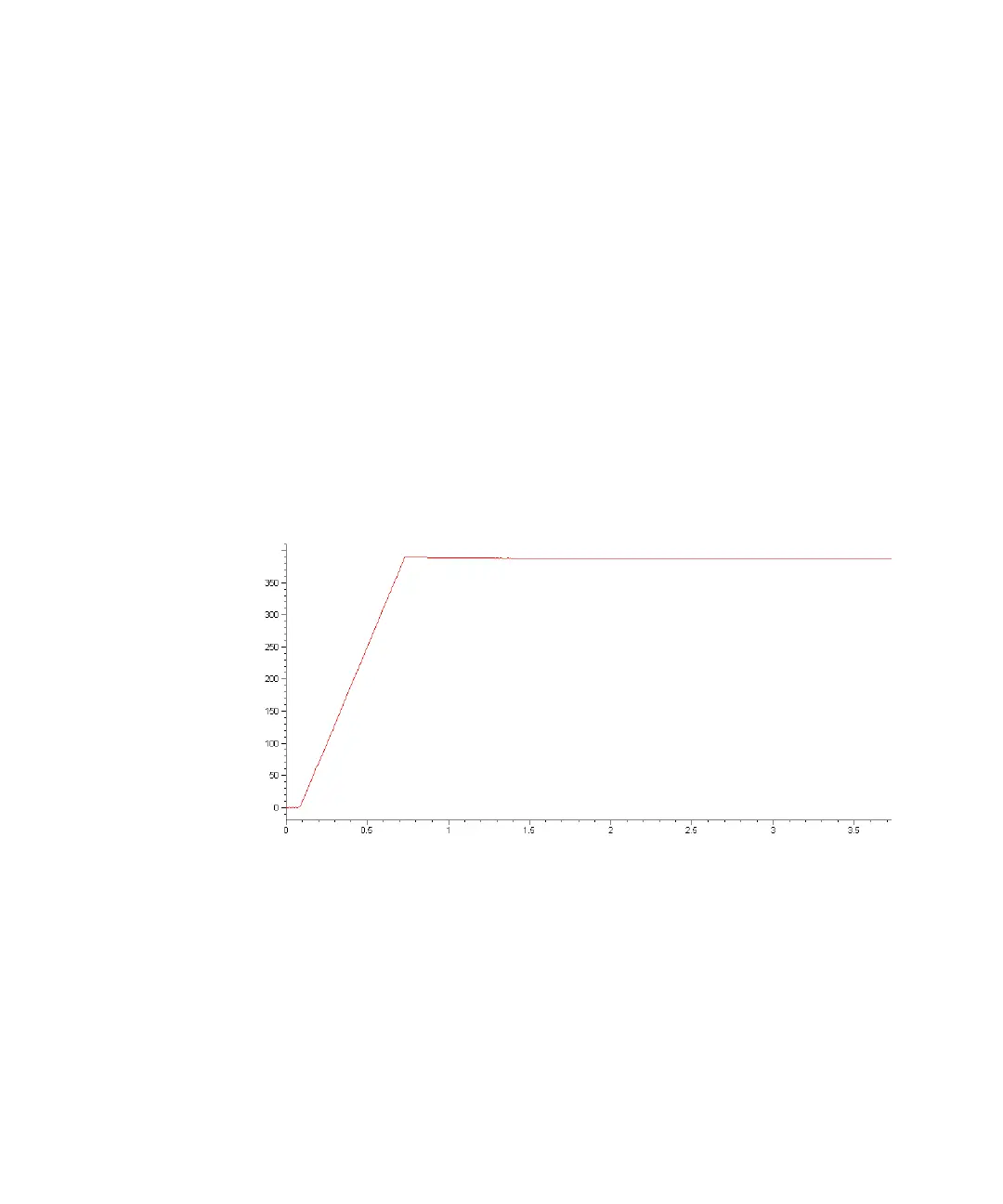

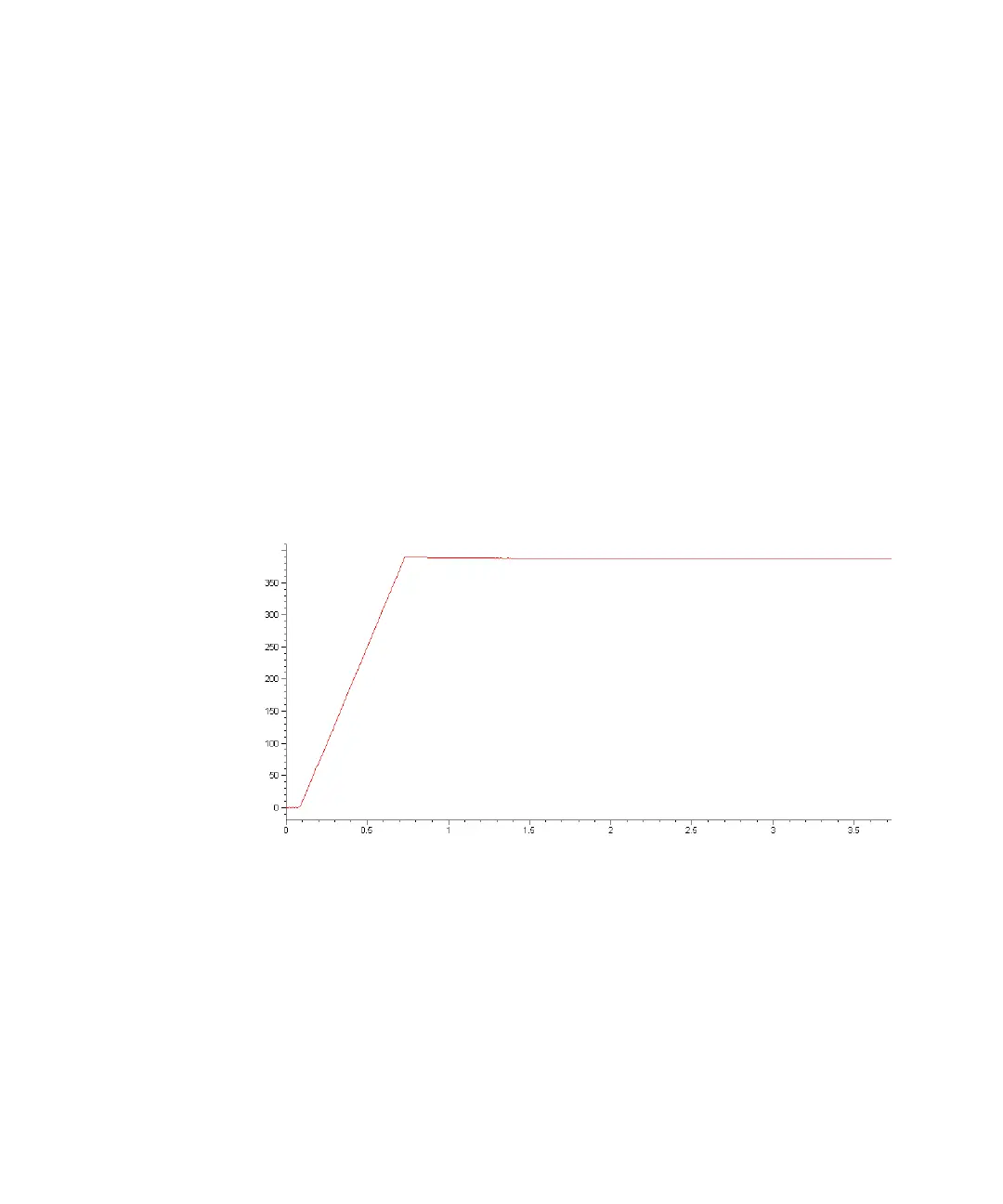

ChemStation). The pressure profile is shown in Figure 8.

Step 1 The test begins with the initialization of both pumpheads. After initialization,

plungers A1 and B1 are both at the top of their stroke. Next, pump A begins

pumping solvent with a flow rate of 510 µl/min and stroke of 100 µl. The nano

pump continues to pump until a system pressure of 390 bar is reached.

Step 2 When the system pressure reaches 390 bar, the nano pump switches off. The

pressure drop from this point onwards should be no more than 2 bar/minute.

Figure 8 Typical Pressure-Test Pressure Profile with IPA

Time [minutes]

Pressure

[bar]

Step 1

Step 2

Loading...

Loading...