258 1100 Series Nano Pump Service Manual

7Specifications

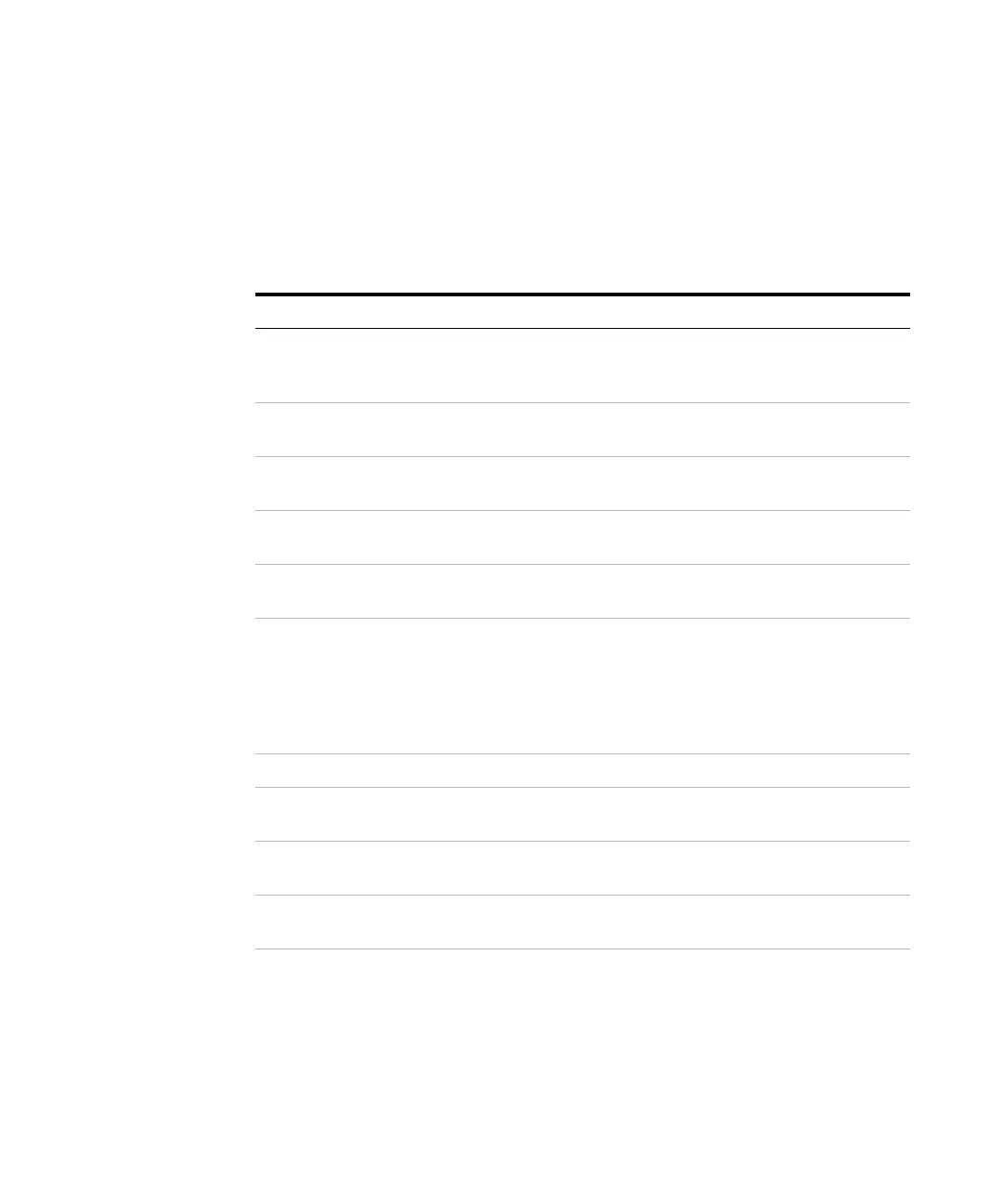

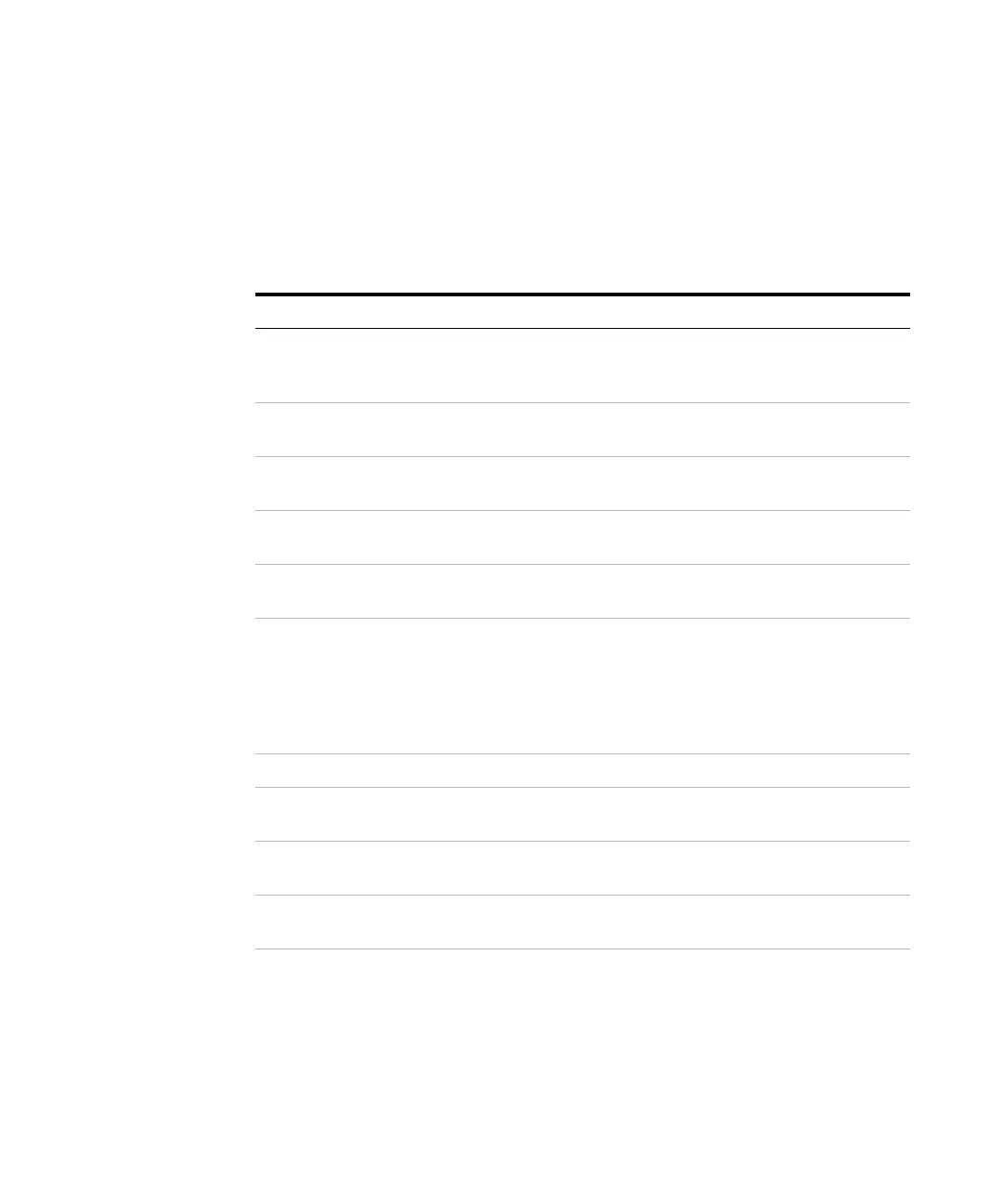

Performance Specifications

Table 63 Performance Specification Agilent 1100 Series Nano Pump

Type Specification

Hydraulic system Two dual piston in series, with proprietary servo-controlled variable

stroke drive, floating piston, active inlet valve, solvent selection valve

and electronic flow control for flow rates from 0.1 to 1 µl/min

Settable column flow

range

0.01 – 4µl/min

1 – 2500 µl/min (with the electronic flow control bypassed)

Recommended column

flow range

0.1–1µl/min

200 – 2500 µl/min (with the electronic flow sensor bypassed)

Optimum composition

range

1 to 99% or 5 µl/min per channel (primary flow), whatever is greater

Composition precision < 0.2 % SD, at 500nl/min (default settings),

Minimum primary flow/pump channel is 5µl/min

Delay volume Typically 300 nl from the electronic flow control to the pump outlet for

flow rates up to 4 µl/min. For flow rates up to 4 µl/min and electronic

flow control active: primary flow path 180 - 480 µl; system pressure

dependent (default settings; calculated volume)

Typically 180 to 480 µl (system pressure dependent) for flow rates up to

2.5 ml/min. (default settings; calculated volume)

Pressure range 20 to 400 bar (5880 psi) system pressure

Compressibility

compensation

User-selectable, based on mobile phase compressibility

Recommended pH

range

1.0 – 8.5, solvents with pH < 2.3 should not contain acids which attack

stainless steel. Upper pH range is limited by fused silica capillaries.

Control and data

evaluation

Agilent ChemStation for LC

Analog output For pressure monitoring, 2 mV/bar, one output

Communications Controller-area network (CAN), GPIB, RS-232C, APG Remote: ready,

start, stop and shut-down signals, LAN optional

Loading...

Loading...