Chapter 5: Routine Operational Procedures

5/21

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

8.- Set the Delay (only in expert level)

You will have to set the delay for each new camera.

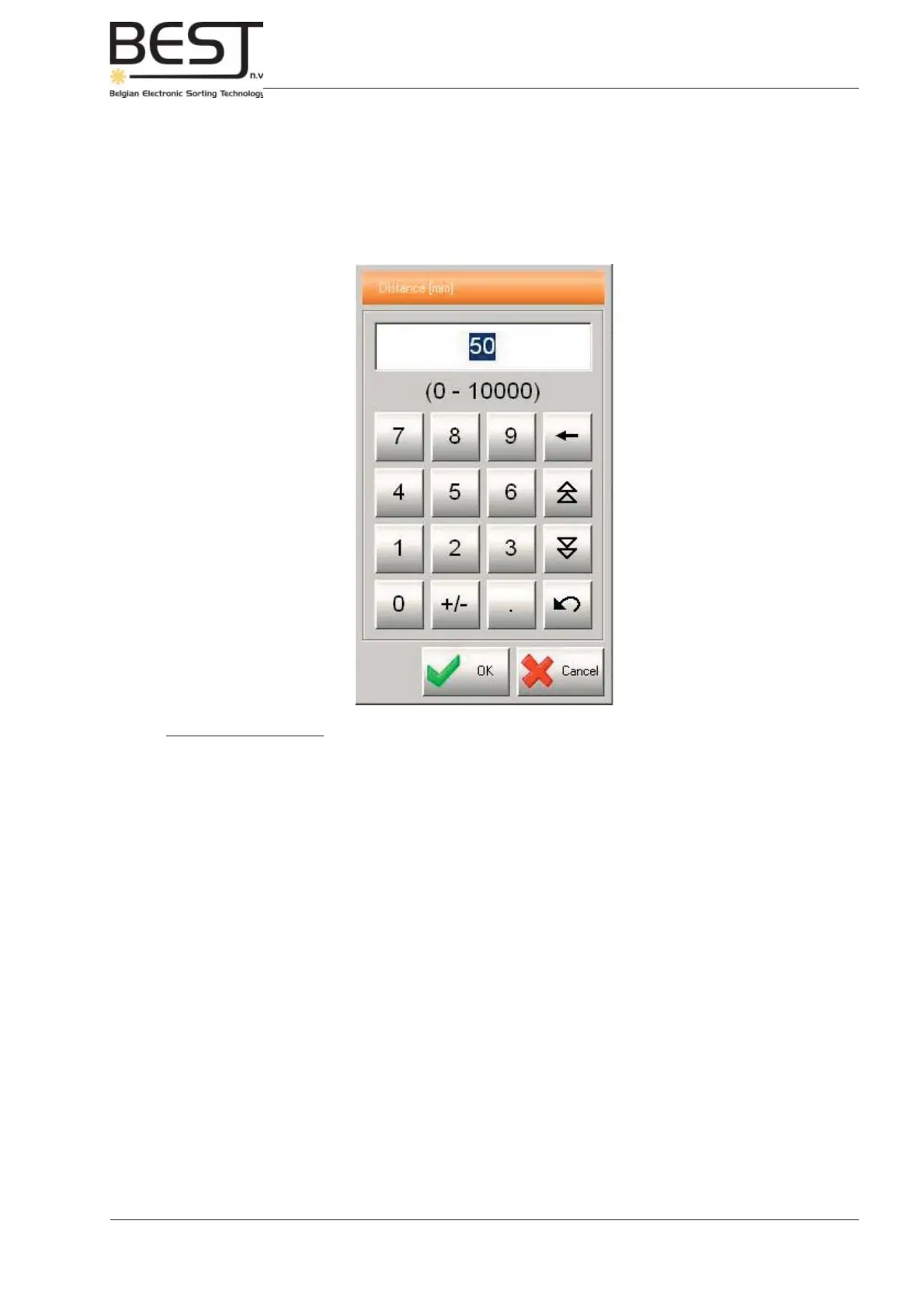

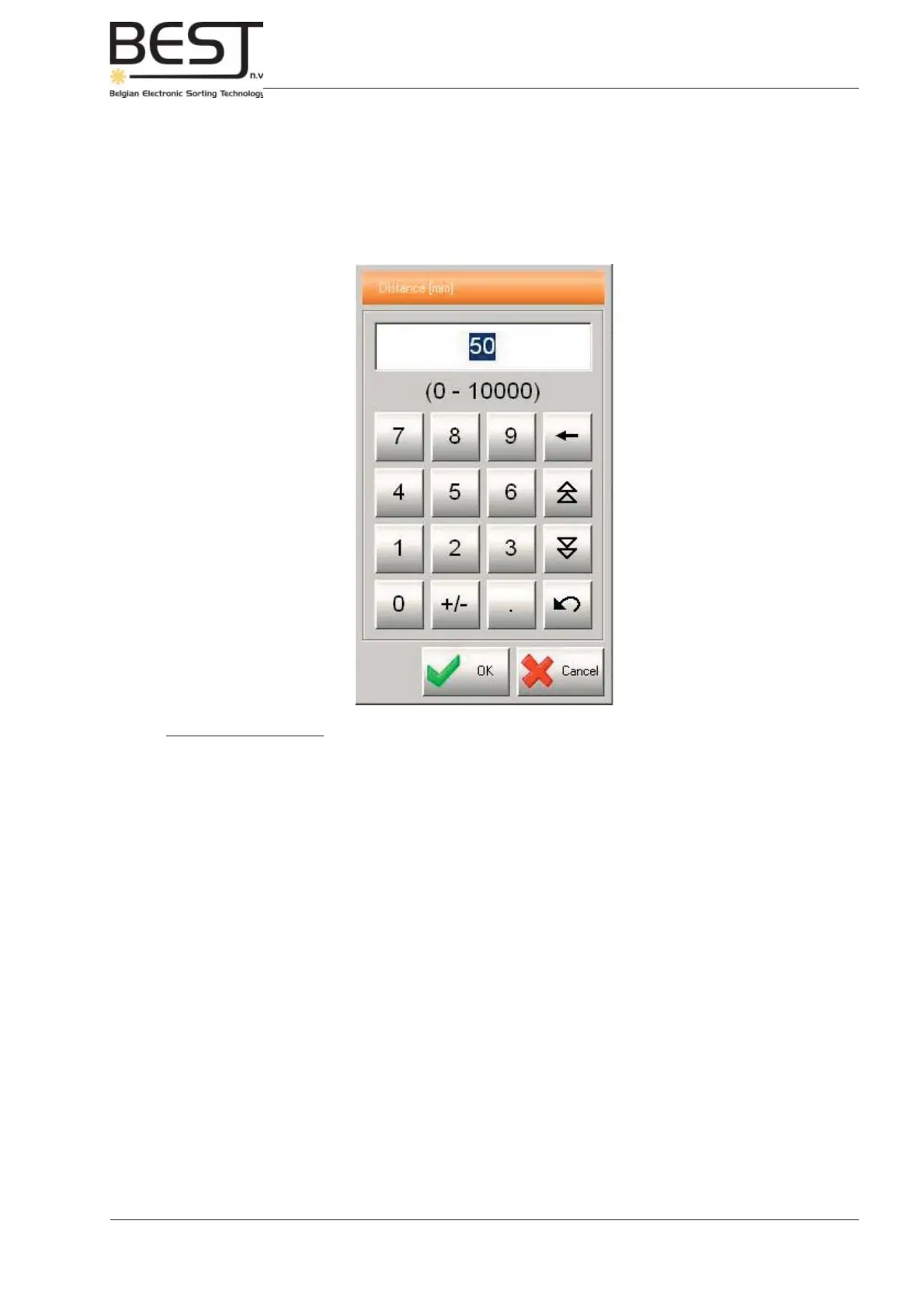

Adapt the Delay value by using the + and - buttons after Delay in the centre of the menu, or by

pressing the value after Delay. An input menu will appear (see picture).

Procedure to set Delay:

- 1. Set one of the thresholds (of the appropriate device: laser/camera) in such a way that

everything except the belt itself is detected:

- Activate the appropriate camera/laser and raise the threshold until the GENIUS

Compact starts detecting the belt (air guns will be activated on an empty belt).

- Next lower the threshold a little until it stops detecting the belt.

- 2. Put a number of defects that will certainly be detected (e.g. black pieces) on the belt

and switch it on.

- All defects should end up in the reject chute.

- 3. Increase the delay gradually, with units of 5 or 10 mm, until some defects are missed

and end up in the accept.

- Write this distance down.

- Lower the distance again: all defects end up in reject chute.

- 4. Decrease the delay gradually, with units of 5 or 10 mm, until some defects are missed

and end up in the accept.

- Write this distance down.

- Calculate the average value and enter it.

- 5. Repeat steps 1 to 4 for all the other devices: cameras/lasers present in your

machine confi guration.

Loading...

Loading...