EPSON Stylus COLOR 3000

EPSON Stylus Color 3000 Service Manual

-3

6.3 Lubrication and Adhesion

Use of lubricants and adhesives has a considerable effect on the performance and durability of the printer.

Lubrication requires appropriate selection of the lubricant, especially at extreme temperatures. Apply

lubricants and adhesives specified in this service manual, which are chosen based on the analysis of

technical information and results from the experimental use of a wide range of lubricants and adhesives.

Clean the lubrication points before lubricating. Lubricate the printer periodically according to the

specifications. Make sure the printing mechanism is clear of dirt or dust after cleaning, disassembling, or

assembling the printer. Adhere all specified parts when assembling the printer or replacing the parts. Use an

adequate amount of adhesive, and dry it thoroughly since the overflow of surplus adhesive may cause

malfunctions in nearby parts.

The lubricants and adhesives specified for this printer are selected based on evaluations of their

properties when used with this printer. Never apply items that are not listed since use of other items may

result in short printer life and poor printer performance.

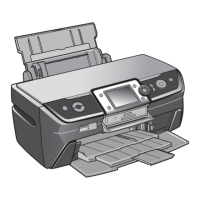

Type Product name Content Part code Applicability

Grease G-26 40 g B702600001 EPSON-exclusive product

Oil O-8 40 g 1019753 EPSON-exclusive product

Adhesive NEJI lock B1401B 1000 g B730200200 EPSON-exclusive product

Reference

No.

Lubrication Points Quantity

1 Front paper guide assembly

– Installation sockets for PF roller and paper eject roller

– Mounting shaft for the gear (11.5)

G-26 (3-5 g)

2 Shaft in the paper eject roller assembly G-26 (3-5 g)

3 Paper eject drive unit

– Points where the PR roller shaft slides.

G-26 (3-5 g)

4 Base frame assembly

– Installation hole where the tractor release shaft is inserted

– 5 points where the tractor release shaft slides

G-26 (3-5 g)

5 Base frame assembly

– Contact points with the CR motor unit

G-26 (3-5 g)

6 2 oil pads in the CR unit and the CR shaft O-8

(0.63 - 0.65 ml)

7 CR guide shaft

– Evenly and thinly over the whole shaft surface

O-8

8 Slope on the tractor release cam G-26 (3-5 g)

9 8 points on the top edge of the paper eject frame G-26 (10-20 g)

CAUTION

Table 6-1. Recommended Lubricants

Table 6-2. Lubrication Points and Application

Loading...

Loading...