Epson Artisan 800/Epson Stylus Photo PX800FW/TX800FW/Epson Artisan 700/Epson Stylus Photo PX700W/TX700W

Adjustment Items and Overview

https://www.manualsbooks.com

5.1.2

Required Adjustments

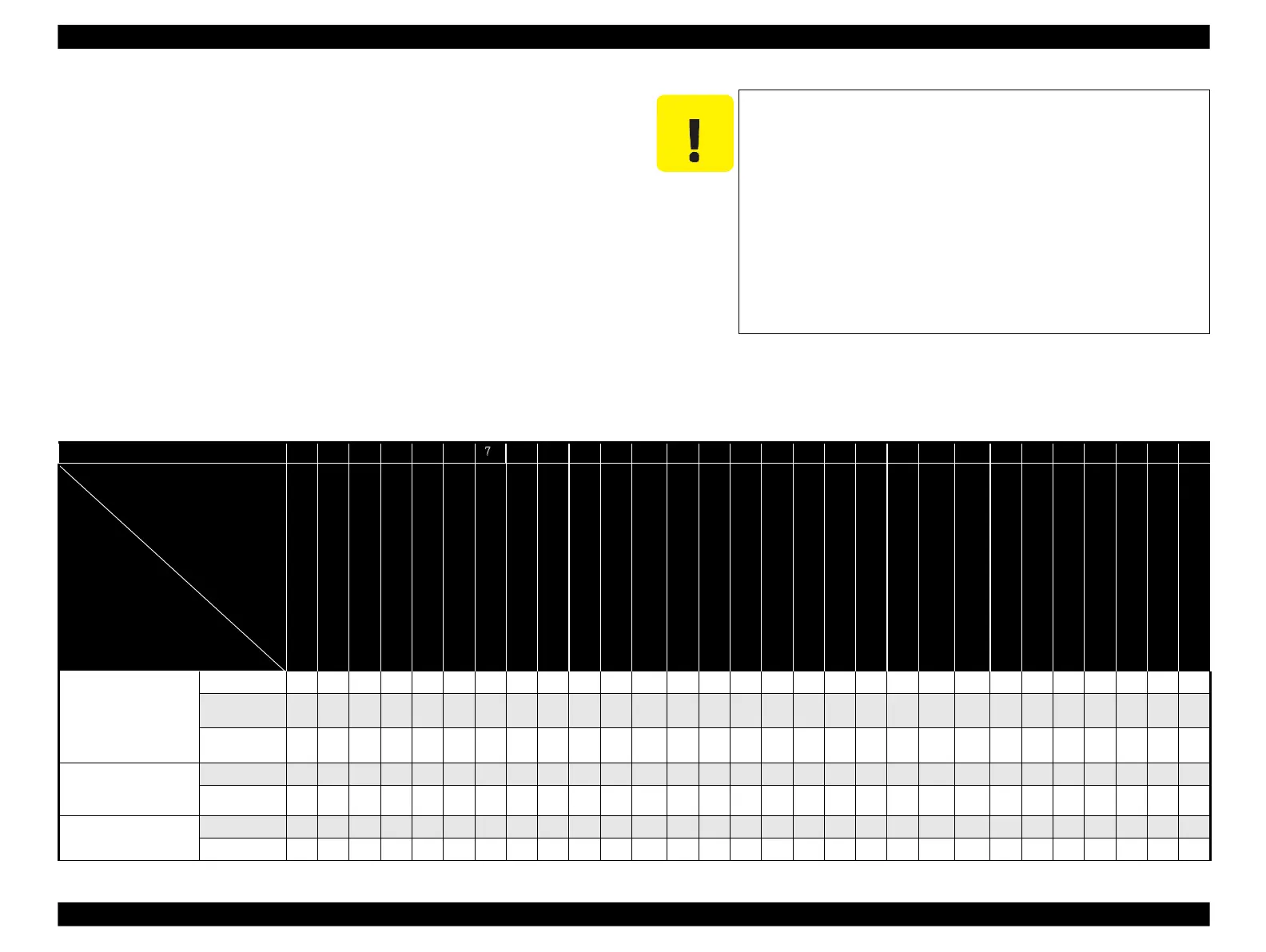

The table below lists the required adjustments depending upon the parts being repaired

or replaced. Find the part(s) you removed or replaced, and check which adjustment(s)

must be carried out.

Note : <Meaning of the marks in the table>

“ O” indicates that the adjustment must be carried out. “ O*” indicates that the

adjustment is recommended. “ ---” indicates that the adjustment is not required.

If you have removed or replaced multiple parts, make sure to check the required

adjustments for the all parts. And when multiple adjustments must be carried out, be

sure to carry out them in the order given in the “ Priority” row.

Note *1 : “ I/S Decompress” is carried out before disassembling. Those with priority 2 or lower are

performed after appropriate removal/replacement. (See 4.2.4.1 “ Printhead (p124) ” .)

*2 : Epson Artisan 800/Epson Stylus Photo PX800FW/TX800FW only.

*3 : Carry out this operation after removing the Waste Ink Tray Assy.

*4 : Carry out "Checking the result of PG adjustment (p239)" only, if the position of the

notch on the Parallelism Adjustment Busings have not changed.

Table 5-4. Required Adjustment List

Adjustment Item

Part Name

CR timing belt tension adjustment

PF timing belt tension adjustment

Initial setting/MAC address Setting

PG offset value adjustment

Consumables maintenance counter

First dot position adjustment

PF deterioration offset (initialize)

PF deterioration offset (Max value writing)

CR motor heat protection control

PF motor heat protection control

Final check pattern print

Panel Unit

(Epson Artisan 800/Epson Stylus

Photo PX800FW/TX800FW Only)

When the EEPROM Data Copy cannot be made for the main

board that needs to be replaced, the Waste Ink Tray Assy, the

Lower Paper Guide Waste Ink Pad Assy and CDR Tray Assy

must be replaced after replacing the main board with a new

one.

After all required adjustments are completed, use the “ Final

check pattern print” function to print all adjustment patterns

for final check. If you find a problem with the printout patterns,

carry out the adjustment again.

When using a new main board for replacing the Printer

Mechanism, the Initial setting must have been made to the main

board.

Loading...

Loading...