CHECK 2

1.

Connect the printer to the computer in which the adjustment program is installed

using a USB cable and turn the printer on, then start the adjustment program.

2.

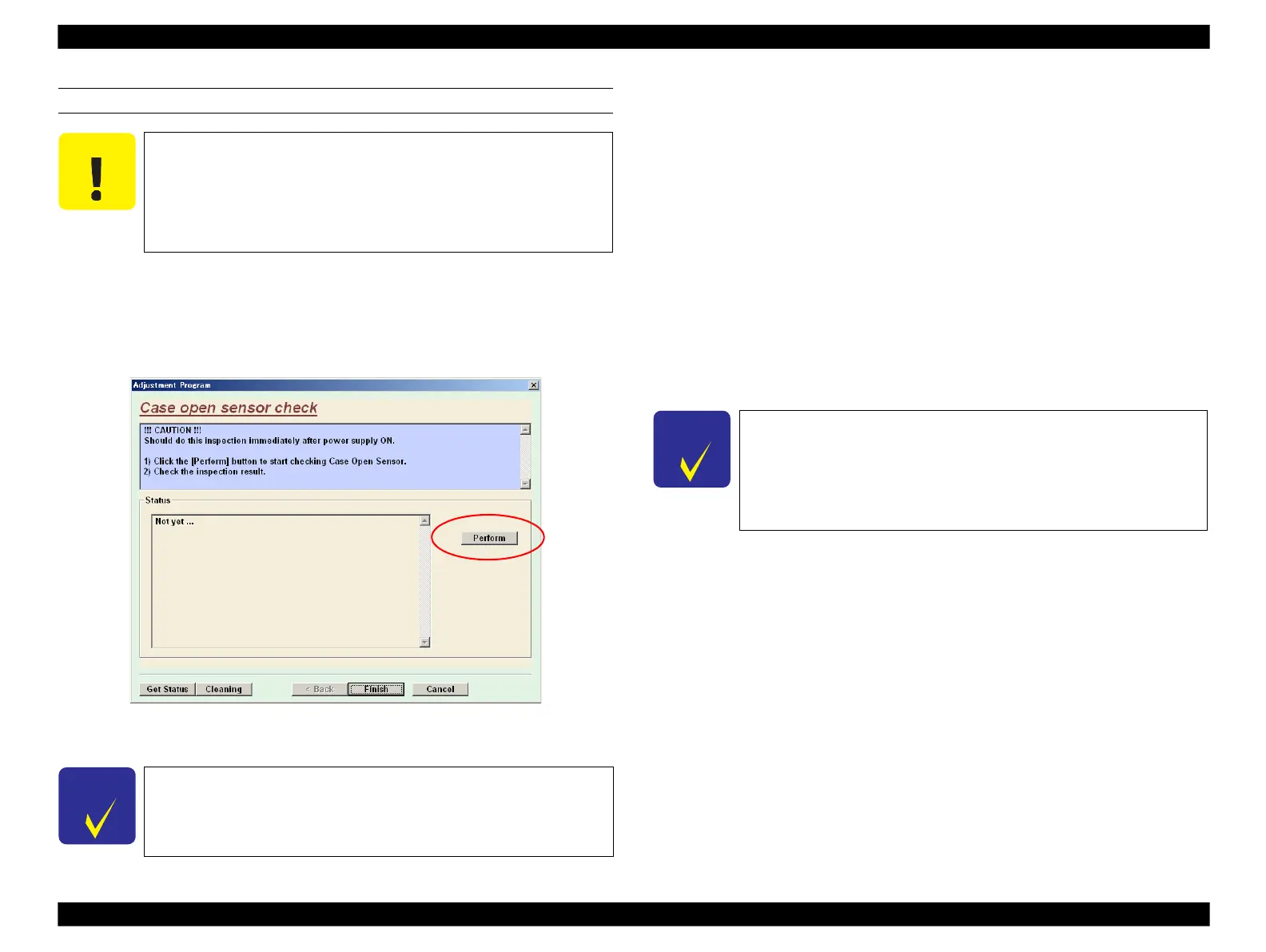

Select “ Case open sensor check” from “ Adjustment” of the adjustment program.

3.

Press the “ Perform” button on the displayed screen; then the adjustment program

automatically checks the cover open sensor.

Figure 5-22. Case open sensor check Screen

4.

This check is complete if the result is “ OK” .

5.2.9

AID inspection

Overview

The printer has an AID mechanism which automatically carries out nozzle check and

runs cleaning according to the number of detected clogged nozzles (AID detection

cleaning). This AID inspection check is performed using the all nozzles and inspects

the AID function if it works properly or not.

Preparation

Before starting the AID inspection check, make sure to carry out the following

adjustments and check.

PG adjustment

Visual check of nozzle check pattern to see if dots are missing.

Confirm the Waste Ink Tray Assy is installed.

Procedure

1.

Start the adjustment program and select the “ AID inspection” from the menu.

2.

Click the Perform button to run the AID inspection.

3.

Check the inspection result displayed on the adjustment program screen.

4.

When the result shows NG, check the following cables to see if they are wrongly

connected or broken.

Cable connection between the Ink System and the AID Board

FFC connecting the Main Board and the AID Board

5.

Run the “ AID inspection” again. If the result still shows NG, replace the AID

Board.

� � � �

� � �

Perform Check 2 at power on immediately after Check 1

(p226).

Even

though

the

sensor

’

s

operation

is

checked

using

the

adjustment program in Check 2, do not run any other function

except the following described in the next procedure until

Check 2 is complete.

If the result is “ NG” in Step 4, check the connection of FFC between

the cover open sensor and the Main Board. If the correct connection

cannot improve the symptom, replace the scanner unit with a new

one.

When you find dot missing on the nozzle check pattern by the

visual check, run manual cleanings repeatedly until the check

pattern is printed without such symptom.

When performing the AID inspection, make sure to do it with

the Waste Ink Tray Assy installed so as to avoid influence on

the electromagnetic noises.

Loading...

Loading...