Epson Artisan 800/Epson Stylus Photo PX800FW/TX800FW/Epson Artisan 700/Epson Stylus Photo PX700W/TX700W

Troubleshooting without Error Message

https://www.manualsbooks.com

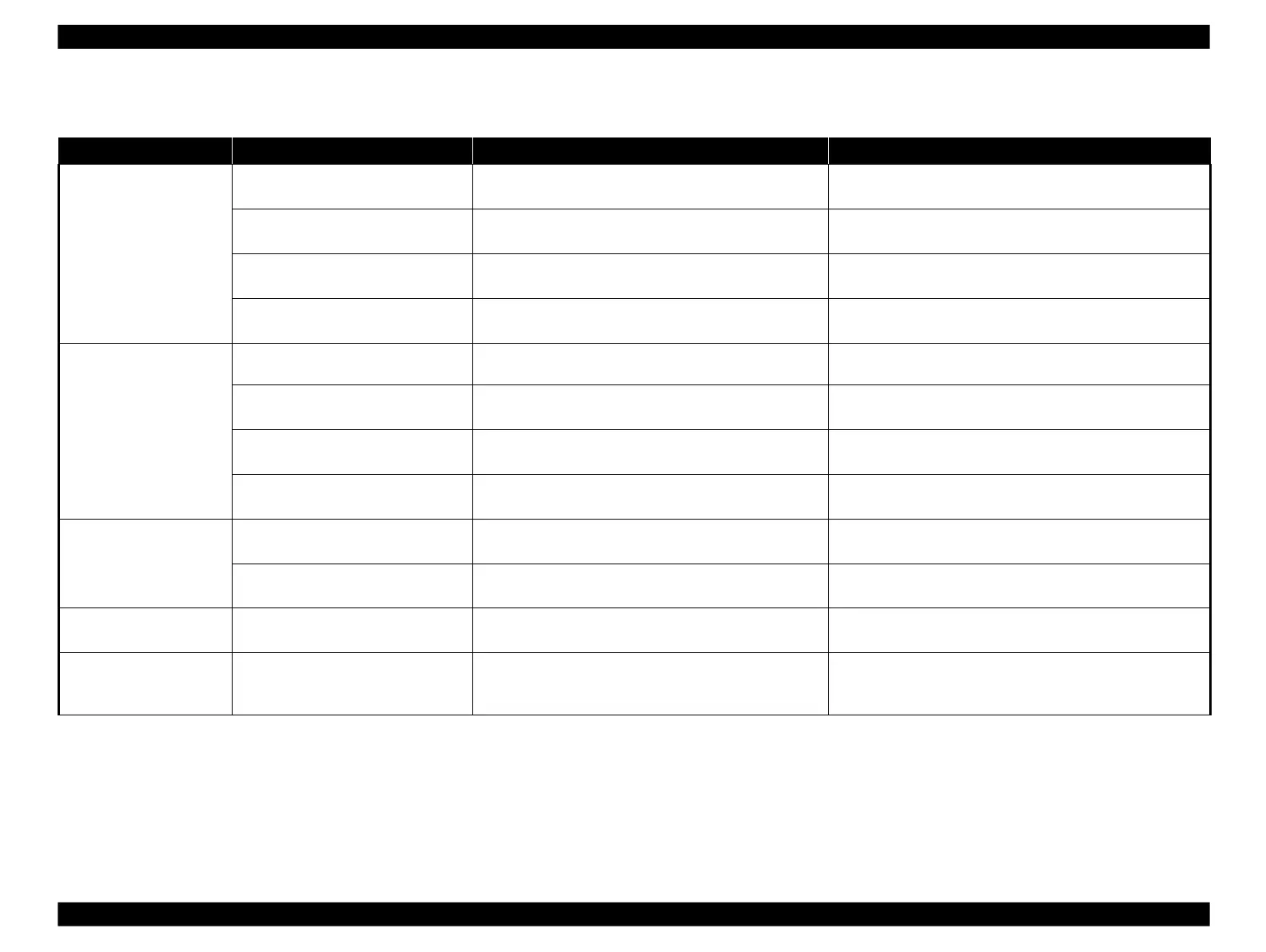

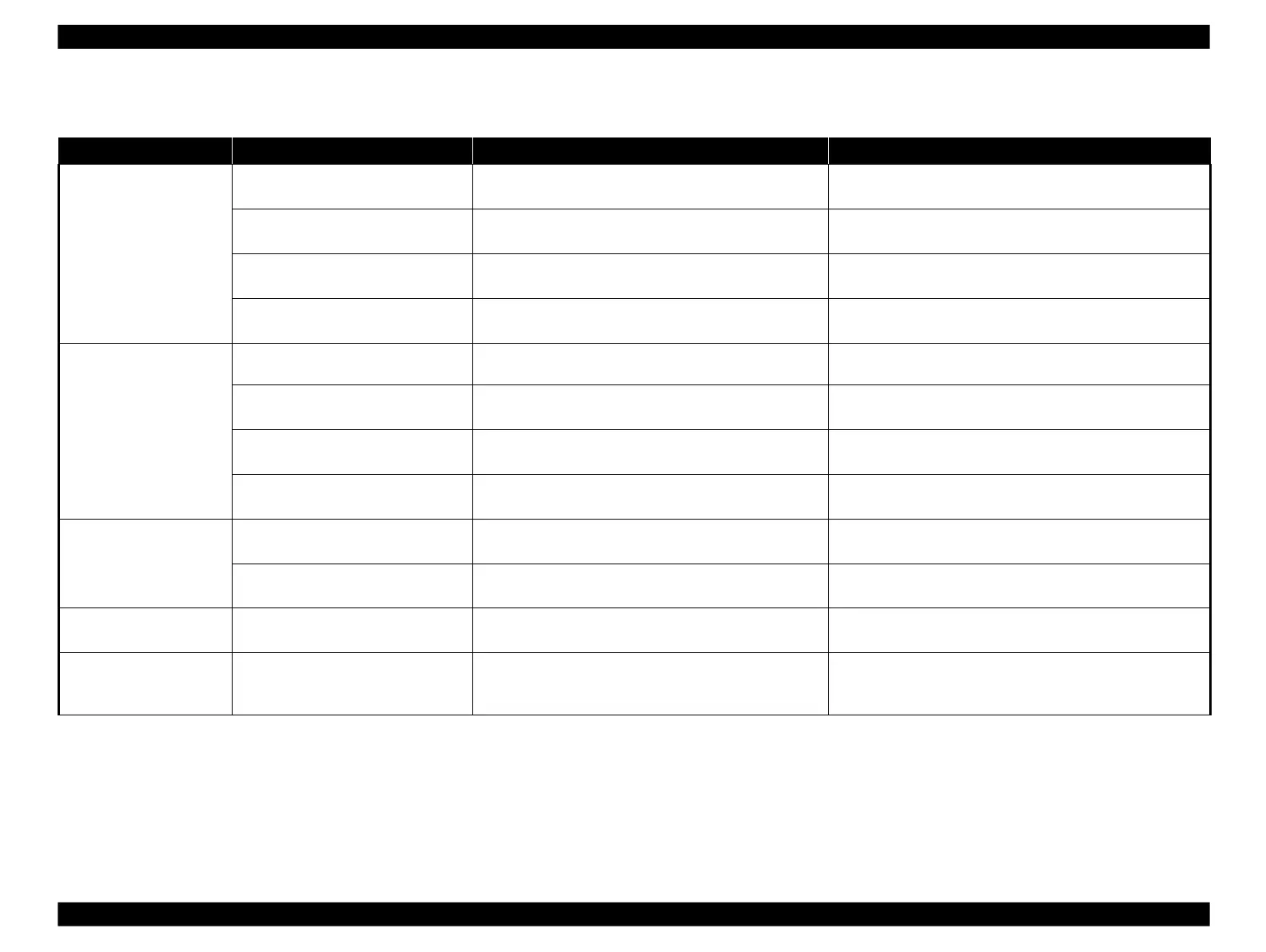

Print quality problems

Table 3-19. Troubleshooting Print Quality Problems

Certain dots are always not

printed correctly

Contamination of the Printhead surface

(dots are missing)

Run a cleaning and make a test print. Repeat it several

times.

Clean the Printhead surface using a cotton-tipped swab.

The capping absorber contacts with the

Printhead surface.

Is the capping absorber deformed or damaged?

Replace the Ink System with a new one. (See 4.2.4.6 " Ink

System " (p.135).)

Check if the Head FFC is damaged. (See 4.2.4.1 " Printhead "

(p.124), 4.2.4.16 " Carriage Unit " (p.154).)

Run a cleaning and nozzle check. Repeat it several times.

If the cleaning does not solve the problem, replace the Printhead

with a new one. (See 4.2.4.1 " Printhead " (p.124).)

Dots are sometimes missing

Contamination of the Printhead surface

(dots are missing)

Run a cleaning and nozzle check. Repeat it several times.

Clean the Printhead surface using a cotton-tipped swab.

Replace the ink cartridges with new ones, and run a nozzle

check.

Replace the Ink cartridges with new ones.

Poor connection of the Head FFC

Check the FFC using a tester. Does the result show

abnormality?

Replace the Head FFC with a new one. (See 4.2.4.1 " Printhead "

(p.124), 4.2.4.16 " Carriage Unit " (p.154).)

Run a cleaning several times, and then run a nozzle check.

If the cleaning does not solve the problem, replace the Printhead

with a new one. (See 4.2.4.1 " Printhead " (p.124).)

Printout is totally abnormal

Poor connection of the Head FFC

Is the FFC securely connected to the boards and Carriage

Unit?

Connect the Head FFC correctly.

Is the Head FFC securely connected to the Printhead?

If no problem is found in the connection, replace the Printhead

with a new one. (See 4.2.4.1 " Printhead " (p.124).)

Vertical lines are not

straight

Has the Bi-D adjustment been carried out properly?

Carry out the Bi-D adjustment. (See 5.2 " Adjustment Using

Adjustment Program " (p.219).)

Ink mist is attached on the

paper.

Anti static cloth on the rear frame is

deformed.

Check if the anti static cloth is correctly formed to touch the

paper.

Attach the anti static cloth again so as to let it touch the paper. If

not improved much, replace the printer mechanism with a new

one. (See 4.2.4.18 " Rear Frame " (p.159).)

Loading...

Loading...