16: PULSE, A/D CONVERSION INSTRUCTIONS

16-2 USER’S MANUAL

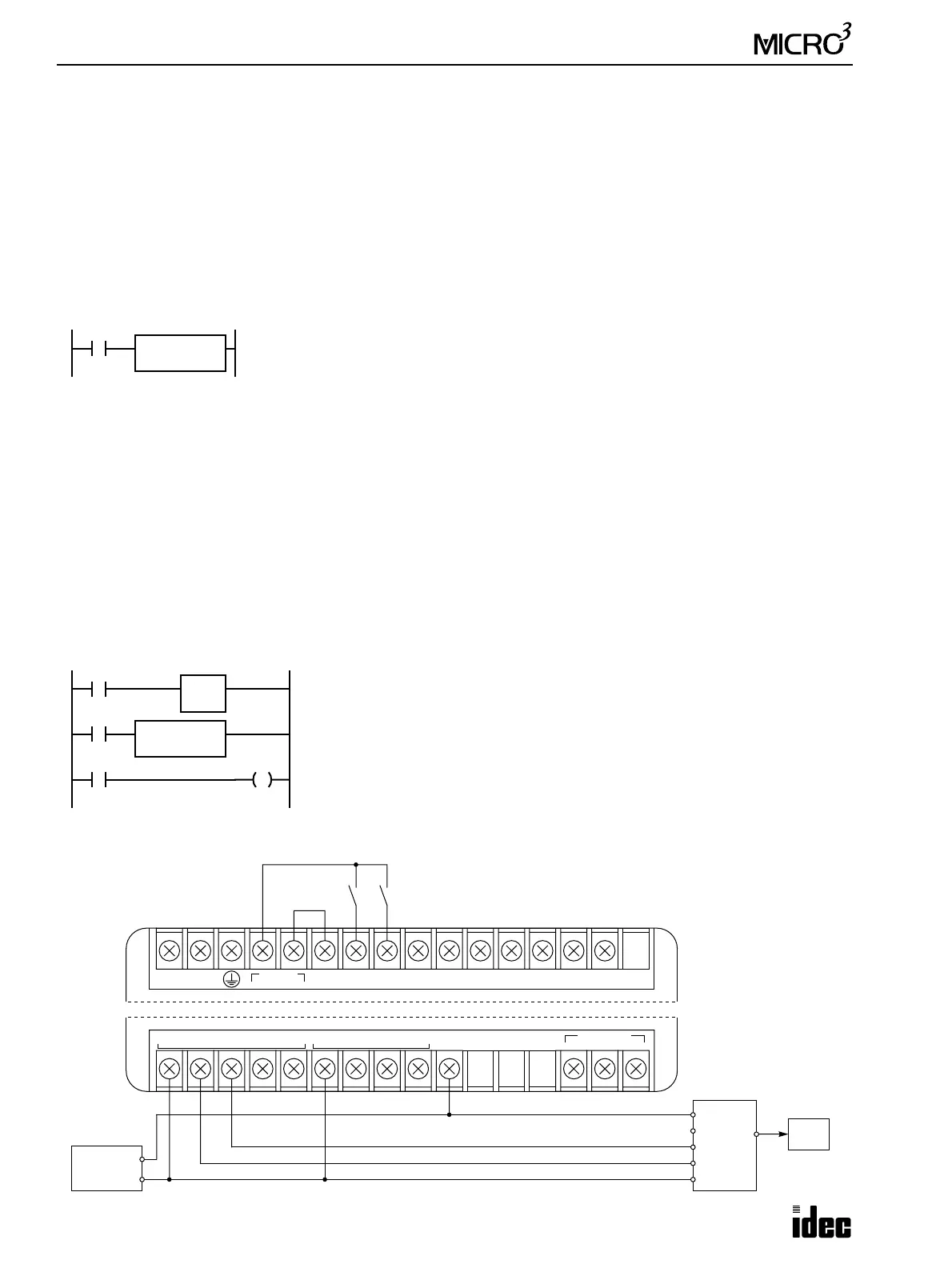

Example: PULS

This example explains how to set 1-kHz output pulses using the PULS instruction.

From the table on the preceding page, MODE 3 and MODE4 can be used to set 1 kHz. If MODE4 is selected, then

Pulse width coefficient 72 should be used as source operand S1.

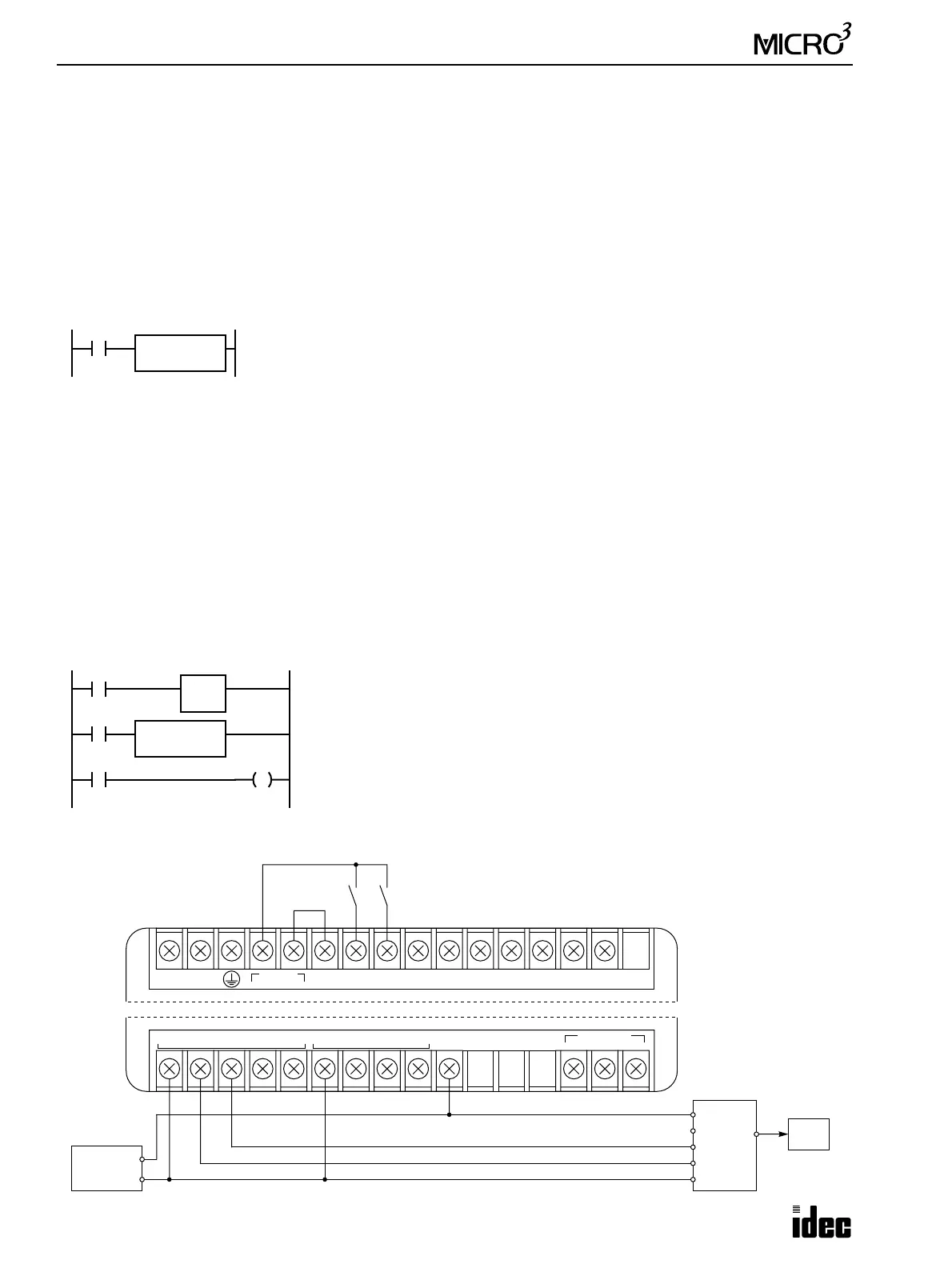

Example: Pulse Motor Speed Control Using PULS Instruction

This example demonstrates a program to control the rotating speed of a pulse motor using the PULS instruction. Analog

potentiometer 0 is used to change the pulse motor speed. When input I0 is on, the pulse output is generated to rotate the

pulse motor. When input I1 is on, the pulse motor rotates in the reverse direction.

Operands

I0 Input to execute the PULS instruction and start the pulse motor

I1 Input to reverse the pulse motor rotation

Q0 Pulse output

Q1 Output to reverse the pulse motor rotation

D10 Pulse width coefficient

MODE1 9.574 through 406.901 Hz

I/O Wiring Diagram

Pulse

Width

Coefficient

S1

Base

Frequency

Output

Frequency 2

×

---------------------------------------------------- 6–=

156250

1000 2

×

---------------------6–=

72.125=

When input I0 is on, output Q0 generates pulse outputs of 1001.6 Hz.

I0

PULS

MODE4

S1

72

Output

Frequency

156250

72 6+

()

2

×

----------------------------- 1001.6

Hz==

M317

PULS

MODE1

S1

D10

I0

ANR0

D10

I1

Q1

M317 is the in-operation output special internal relay which remains on while the

program is executed.

The ANR0 (analog read 0) instruction sets the value of analog potentiometer 0 to

data register D10.

While input I0 is on, the PULS instruction is executed to generate output pulses

determined by the value of D10. Output Q0 sends out the output pulses.

When input I1 is on, output Q1 is turned on to reverse the pulse motor.

OUT

COM0(–)

0123

OUT

COM1(–)

456

DATA LINK

ASGB

+V

+V

CW/CCW

PULSE

GND

Pulse

Motor

+

–

External

Power

24V DC

Motor Driver

100-240V AC

LN

DC OUT

24V 0V

DC IN

COM

0123456710

MICRO

3

Base Unit FC2A-C16B1

(Transistor Sink Output)

Loading...

Loading...