Application Note 653 15

Intel740™ Graphics Accelerator Thermal Design Considerations

5. Join and secure the assembly centering the heat sink on the component. Wait for the adhesive

to fixture (approximately 5 minutes) before any further handling. Full cure occurs in 4-24

hours.

Note: The successful application of this product depends on accurate dispensing on to the parts being

bonded. The manufacturer (Section A, “Sources” on page 23) offers equipment engineers to assist

customers in selecting and implementing the appropriate dispensing equipment for various

applications.

To remove the heat sink after the epoxy has set, the manufacturer recommends applying heat

(70°C - 93°C) to the assembly. When in this temperature range the heat sink can safely be removed

from the component without damaging it.

4.2.3.3 Tape Attach

For users who prefer to attach via Tape, please refer to Section A, “Sources” on page 23 for the

suggested manufacturer and part number. To maximize the bond line contact area and improve

adhesion we recommend using two pieces of tape, one attached to the heat sink and one attached to

the moldcap as shown in Figure 7, Figure 8, and Figure 9. The recommended attach procedure is at

the end of this section.

Figure 7. Tape Layers

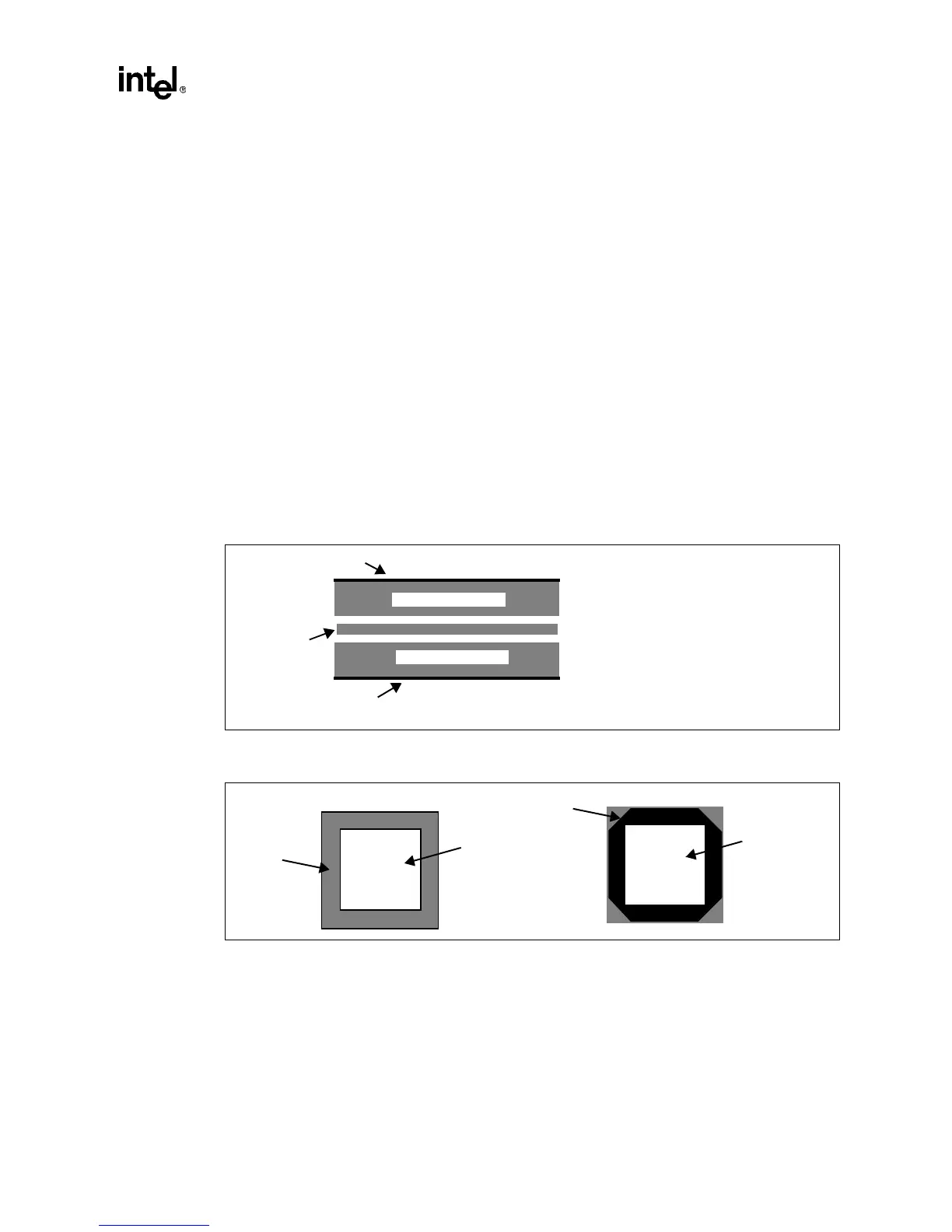

Figure 8. Attaching the Tape to the Package and Heat Sink

Foil

Clear Liner

Non-transparent Liner

Acrylic Adhesive

Silicone Adhesive

Actual Appearance:

Acrylic side appears white,

Silicone side appears silver (foil)

when liners are removed.

Tape:

~ 1"x1” Sq.

Heat

Sink

Tape: May be

larger than applied

to moldcap or pre-

applied by

manufacturer

Moldcap

Loading...

Loading...