2 Machine description

24

BIESSE S.p.A. © - p702k0003.fm251111

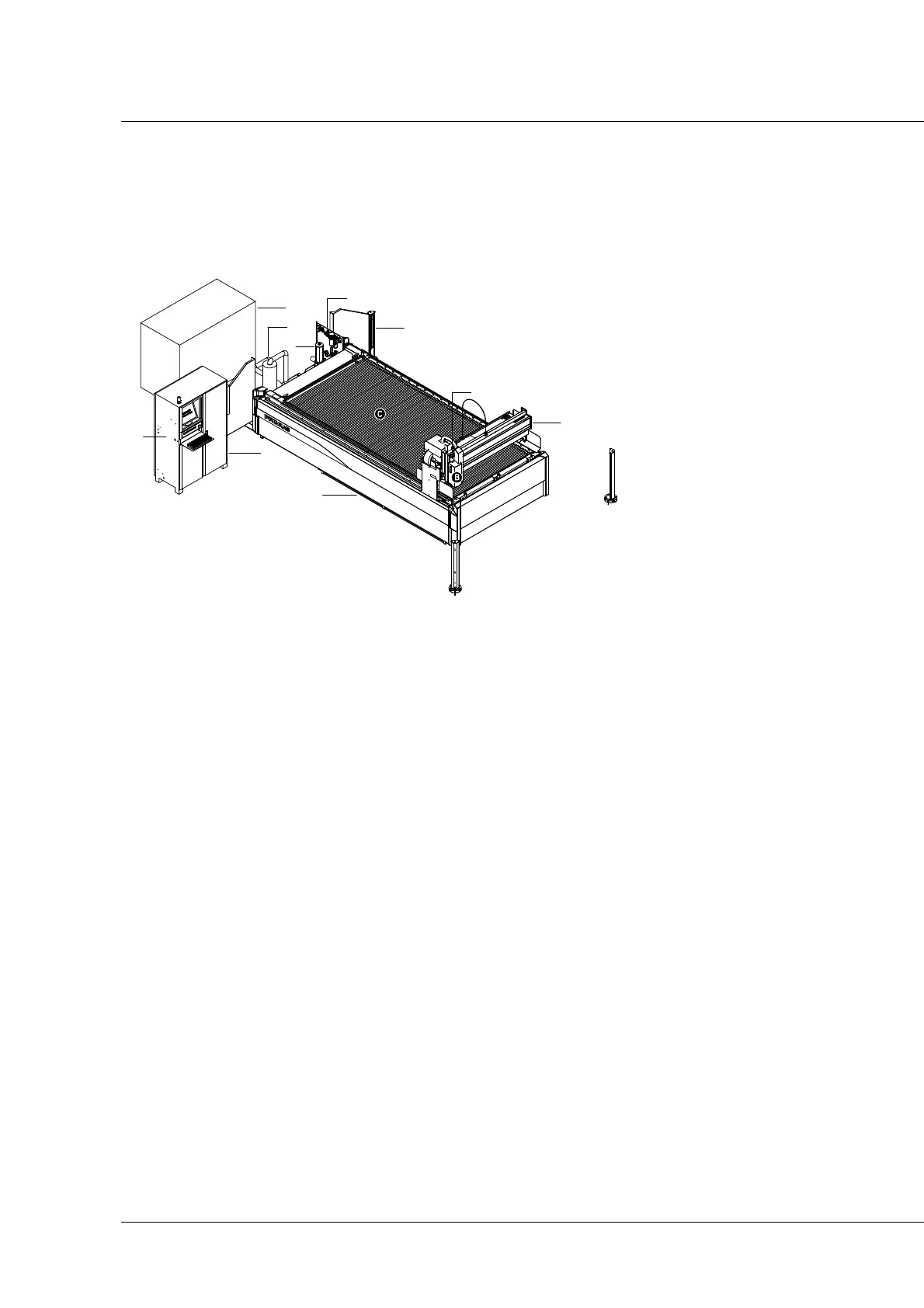

2.3 Primus overview and main parts

A- Base: in the Primus 184, the base is of the single piece type because it is the load-bearing

structure of the machine. It includes the water collection basin and the work table. In the

Primus 322/324 on the other hand, the base is modular and the basin is separate. For further

information, see page 25.

B- Working head: positioned on the mobile beam, it includes the main machining components.

C- Work table: supports the piece during the machining operation. For further information, see

page 29.

D- X-axis mobile beam: supports the working head and slides on guides located at the sides of

the base. For further information, see page 26.

E- Electrical cabinet: contains the main electronic equipment.

F- Numerical control and operator console: used to manage machine operation. For further

information, see chapter 5 “Commands and indicator devices”.

G- Lubrication system: lubricates the less accessible machine parts (slide blocks, guides, etc.).

H- Machining water recirculation system: for treating the machining water in order to separate

out the solid parts. For further information, see chapter 8.

I- Air treatment unit: located on the machine, it regulates the pressure of incoming air and

eliminates moisture and oily residues. For further information, see page 78.

J- Safety guards: prevent access to the dangerous machine areas.

K- UHP intensifier: this unit is external to the machine, and it supplies high pressure water to the

cutting head. For further information, refer to the manufacturer's manual.

L- Abrasive distribution system (optional extra): consists of a propulsor external to the

machine, supplying the abrasive to the batcher located on the working head.

Loading...

Loading...