11 Routine and special maintenance

BIESSE S.p.A. © - p714k0003.fm251111

79

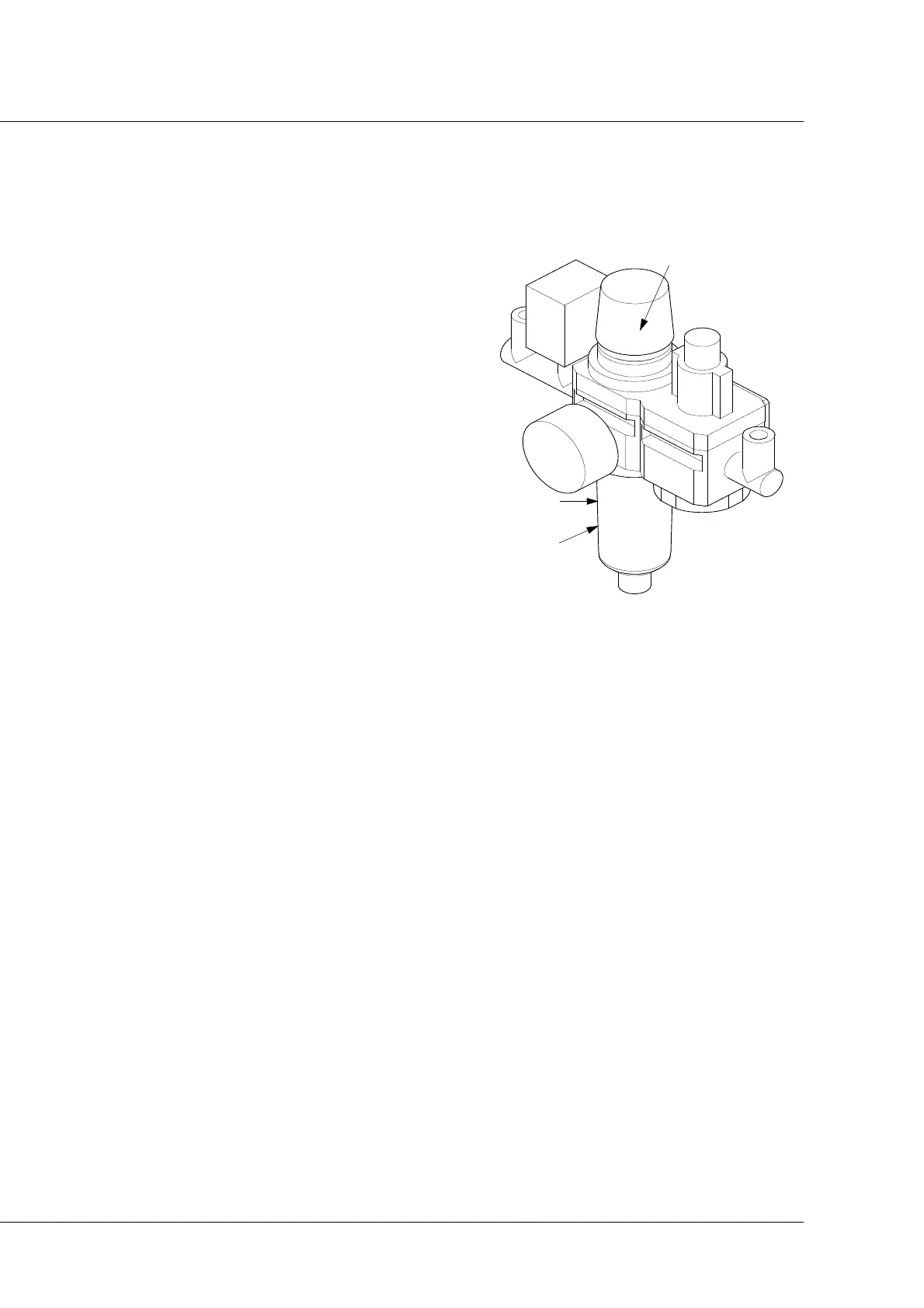

Description

The dynamic dryer filter is made up of the

following parts:

an upper part (A), with the threaded holes

(air inlet and outlet) for connection to the

pneumatic system

a cup (B) with a condensation drainage

device

a 50-micron filtering cartridge (C)

Operating principle

Unlike a traditional filter, the dynamic dryer has 3

distinct operating phases in which the fluid is

"processed" to eliminate the liquid and solid

particles.

Phase 1: expansion

In this phase, the fluid is expanded. This

causes a reduction in the temperature and

the consequential condensing of the water

vapour particles.

Phase 2: centrifugation

In this phase, the fluid makes a circular movement inside the cup. As it follows its obligatory

path, the fluid is also forced to accelerate. The centrifugal force generated tends to carry the

water particles outwards because they are heavier, so they deposit on the inner walls of the

cup and then on the bottom.

Phase 3: filtering

A 50-micron filtering cartridge holds back all the solid particles above 50 microns.

Cleaning and replacing the dryer filter

To clean and replace the filter, proceed as follows:

Make sure there is no pressure in the system; the pressure indicated on the pressure gauge

must be 0 bar.

Remove the filter cup A (to do this, lower the lever B).

Turn the cup 45° clockwise and then pull it downwards to remove it.

To remove the filtering element D, turn the ring nut C clockwise.

Clean the cartridge with water, soap and compressed air or, if necessary, replace it.

Clean the cup, removing any deposits.

To reassemble, follow the above steps in the reverse order.

Loading...

Loading...