11 Routine and special maintenance

72

BIESSE S.p.A. © - p714k0003.fm251111

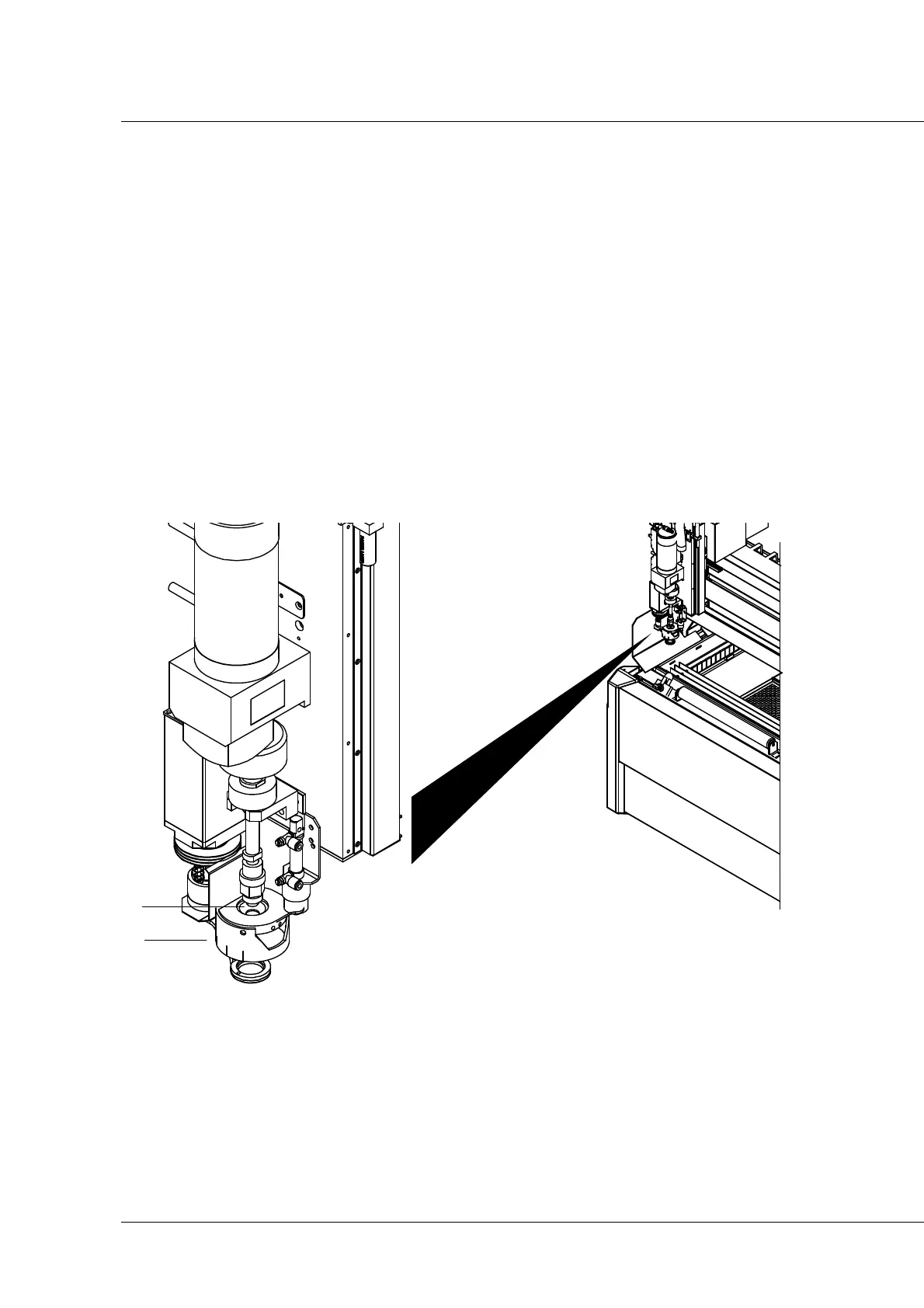

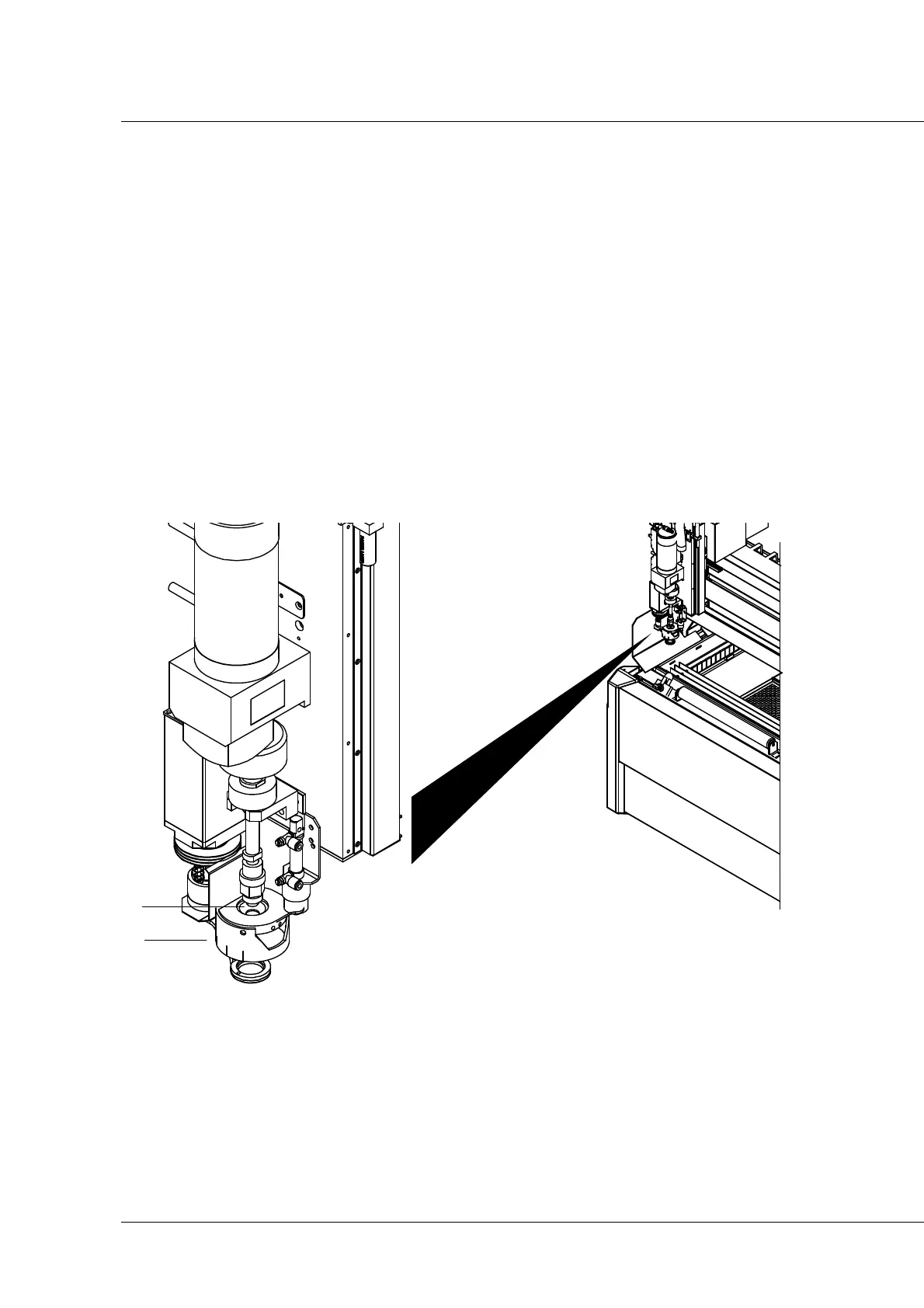

Maintenance of the working head

Daily

Check the abrasive delivery tube (if present) as it is subject to wear as a result of contact with the

abrasive itself. The tube may become excessively thin in places, then holes could lead to the

leakage of material and a consequential reduction in cutting power.

Make a visual check of the abrasive distribution system, ensuring there are no anomalies in the

passage from the propulsor to the batcher.

Weekly

Check the protective hood A on the cutting head is in good condition, with no tears that would

compromise the force of the jet during the cutting operation.

When necessary

The orifice and focusing nozzle are cutting head components that are subject to wear. The high

pressure jet must be visually inspected (without touching it under any circumstances) to make sure

it does not open out too much when leaving the focusing nozzle. Figure 2 shows the correct jet,

while figure 3 shows a worn jet.

Replace the orifice (fig.1) or focusing nozzle (fig.2), or both if necessary, using the special keys

supplied.

Loading...

Loading...