11 Routine and special maintenance

76

BIESSE S.p.A. © - p714k0003.fm251111

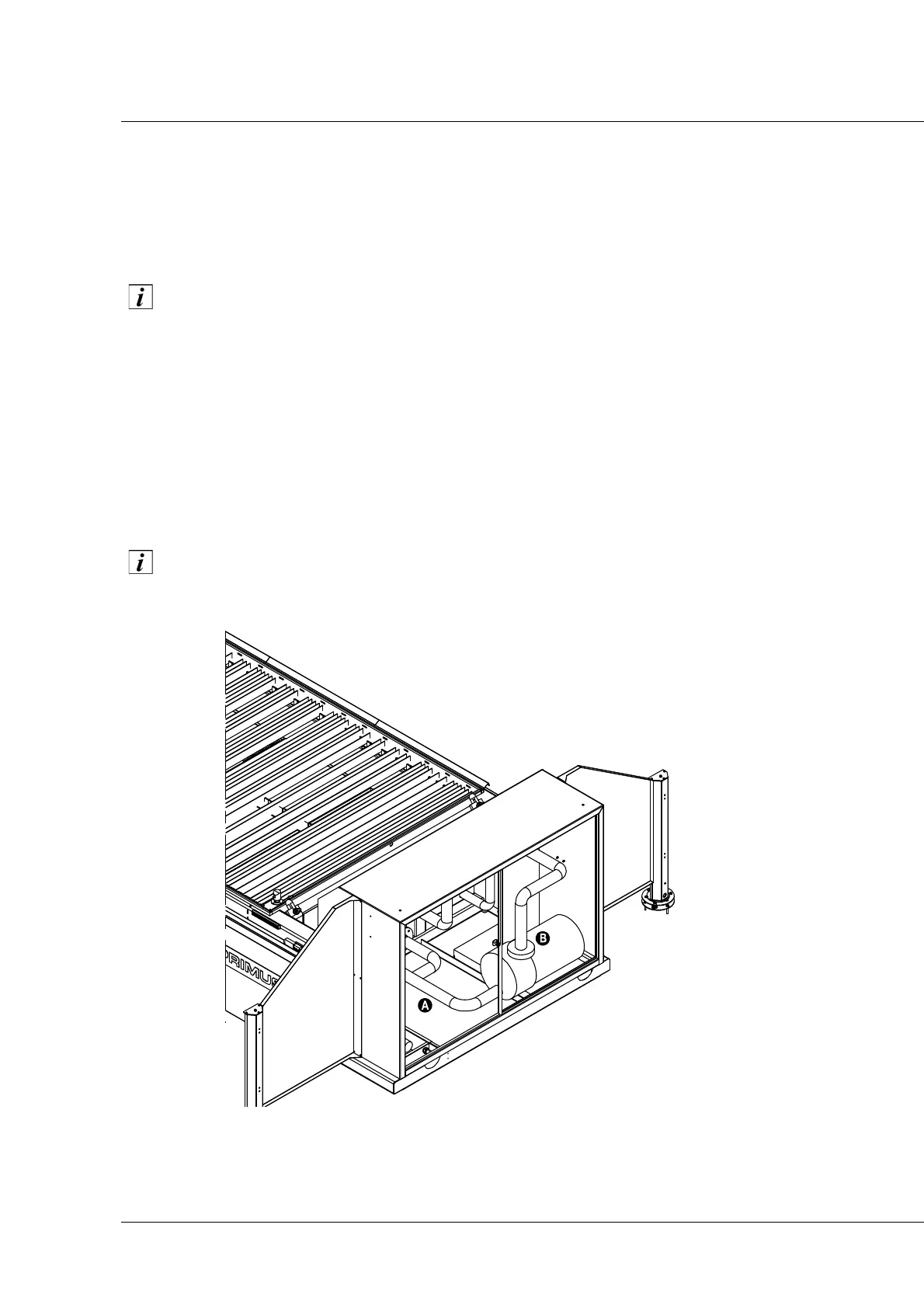

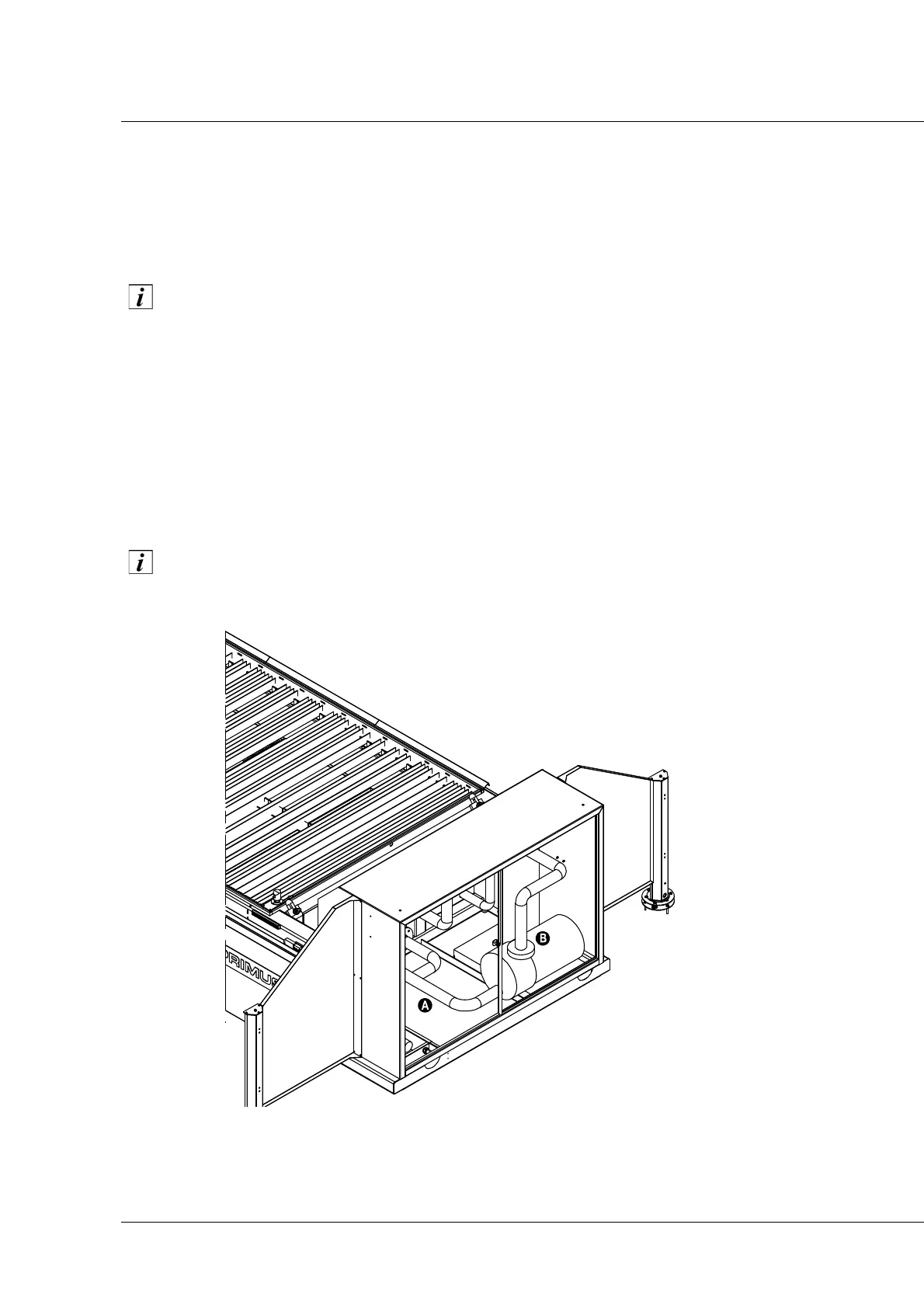

Maintenance of the machining water recirculation system

The recirculation system separates the solid parts from the machining water. The main parts of this

system are the pump, the centrifugation separator, and the solids recovery unit (optional).

Maintenance interventions must only be carried out with the system switched off, unless

indicated otherwise.

Every day, check the level of the solid waste that accumulates in the drainage bag (if present). If

necessary, replace it and dispose of it in accordance with the local and national regulations in

force.

Every day, check the level of lubricant in the tank B on the upper part of the pump. This check must

be carried out with the system operating.

Top up the level with an oil such as “Mobil Vactra Heavy” or “BP Energol HLP-HM100”.

Every year, replace the used oil and check for any water infiltrations; check the oil is not highly

emulsified.

If you notice any anomalies, contact the manufacturer.

Never fill the tank right to the top.

Every month, clean out the suction filter A, removing the cap with the key supplied (or manually on

models with knobs).

Loading...

Loading...