11 Routine and special maintenance

BIESSE S.p.A. © - p714k0003.fm251111

83

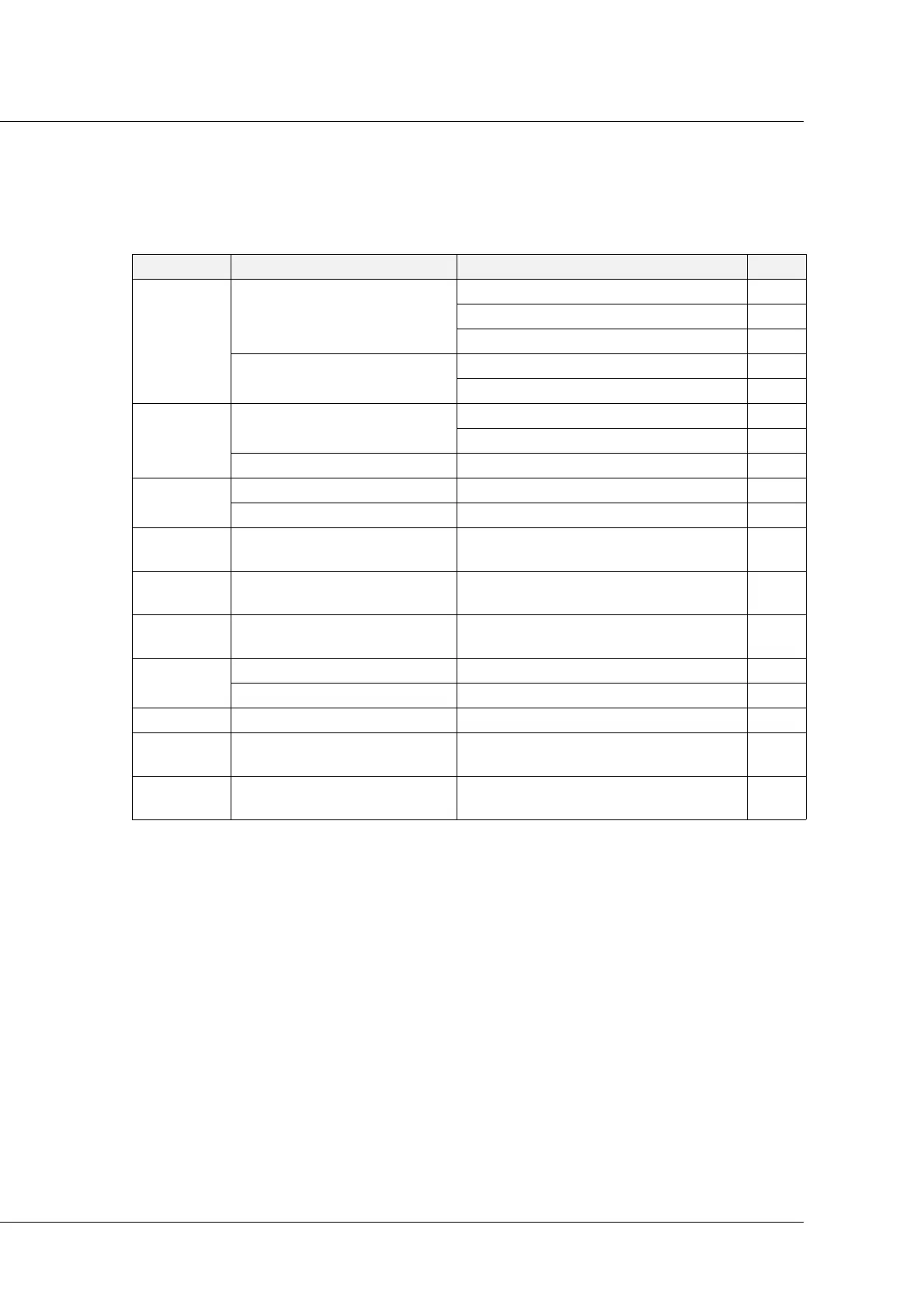

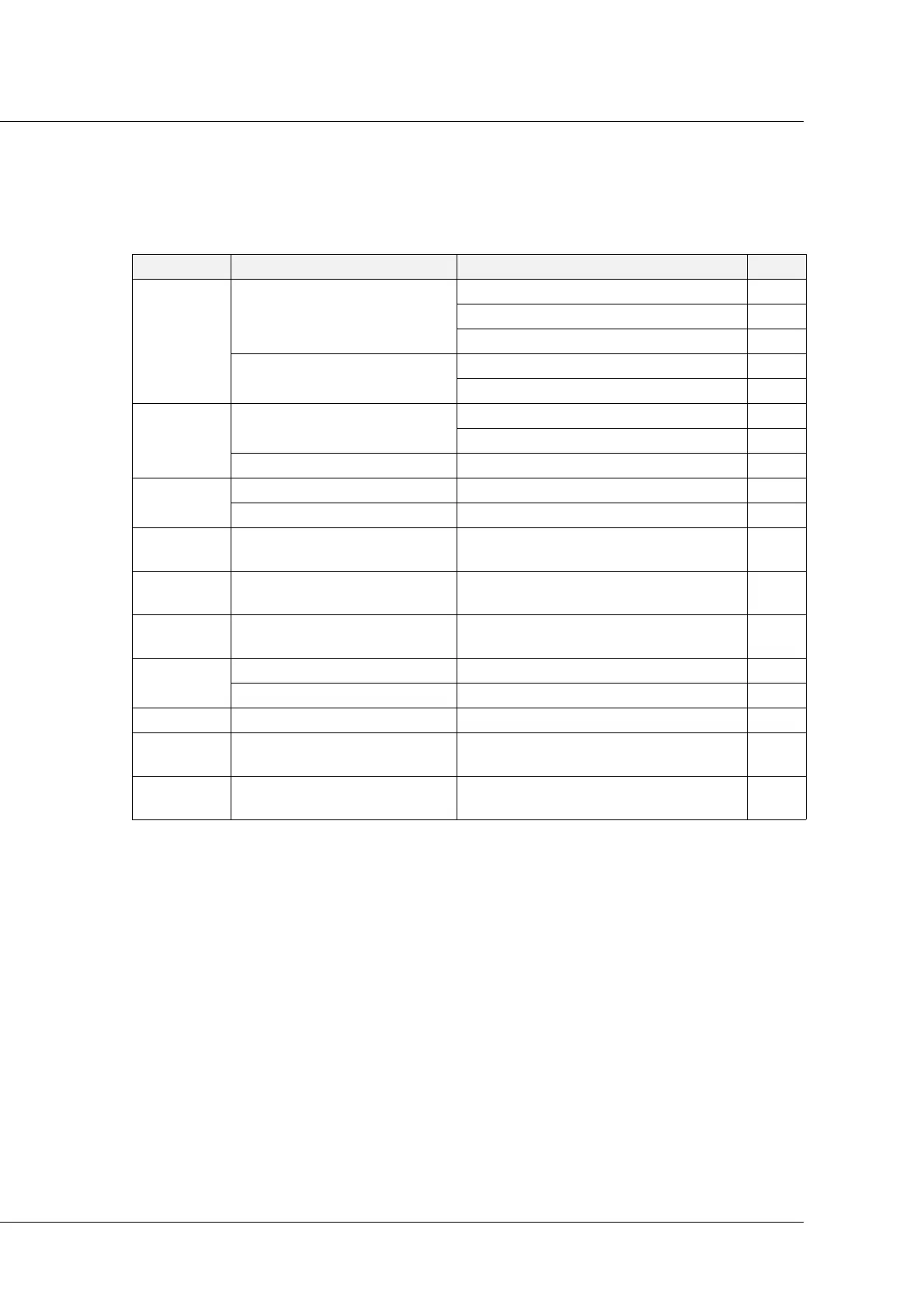

11.1.2 Summary and frequency of maintenance operations

Frequency Part involved Operation Page

Daily Machine “Cleaning” 68

“Cleaning the work table” 69

Check abrasive delivery tube 72

Recirculation system Check level in drainage bag

Check level of lubricant in pump

Weekly Cutting head Check the protection hood

Lubrication system “Checking lubrication” 74

Monthly Machine “Cleaning the guides” 71

Recirculation system Clean the suction filter

Every 900

-1800 hours

Dryer filter “Cleaning and replacing the dryer filter” 79

Every 6

months

Machine “Cleaning the machining operation

basin”

70

Every 3000

hours

Oil separator filter “Replace the oil separator filter” 81

When

necessary

Machine Clean the decantation basin

Cutting head Replace the orifice and focusing nozzle

Annually Recirculation system Replace the oil in the pump

Every 3

years

Recirculation system “Maintenance of the pump in the

machining water recirculation system”

85

*

*

The unit is fitted with a sensor that checks the level of lubricant. When the minimum level is reached, a message

appears on the monitor to tell the operator to top up the level.

Centralised lubrication system “Topping up the level of lubricant in the

pump”

75

Loading...

Loading...