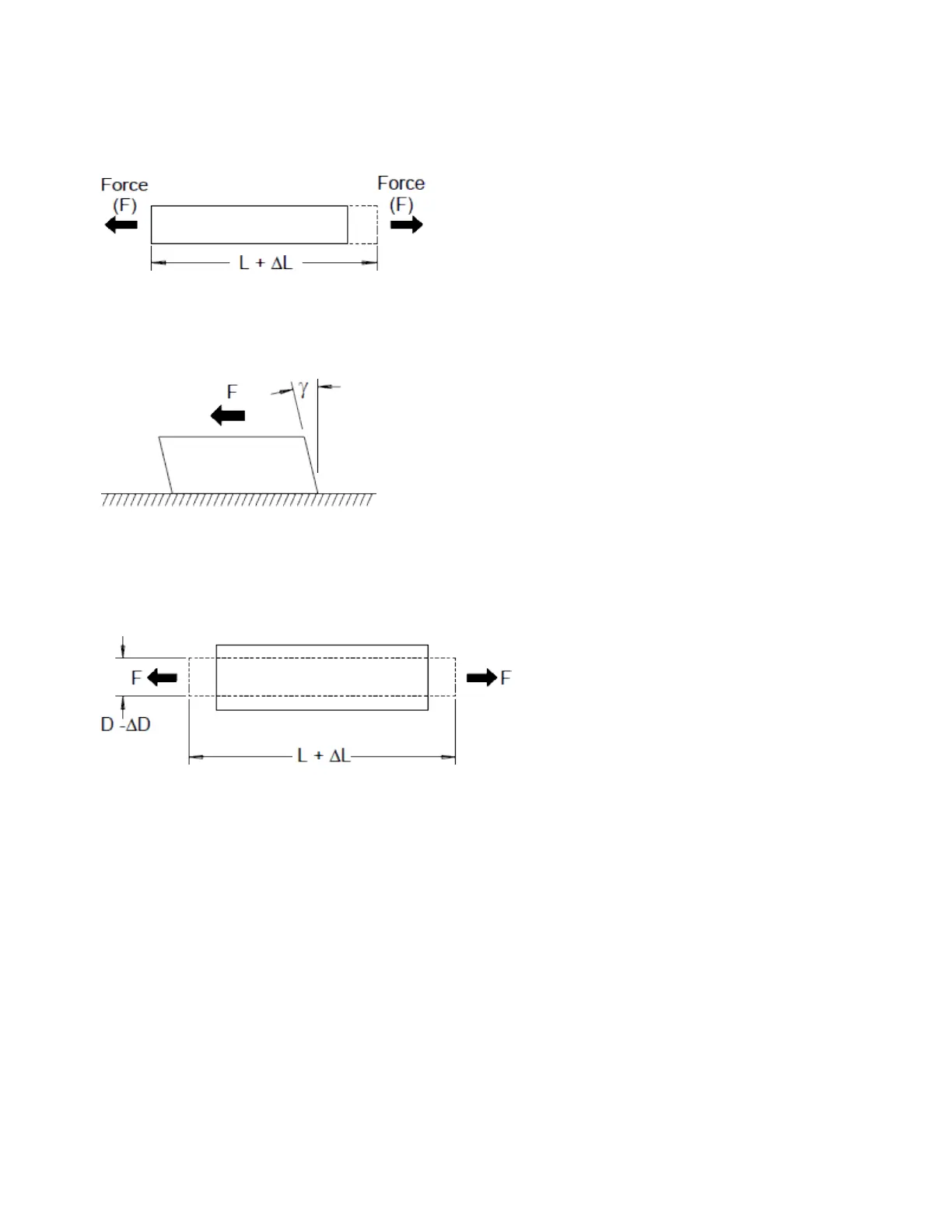

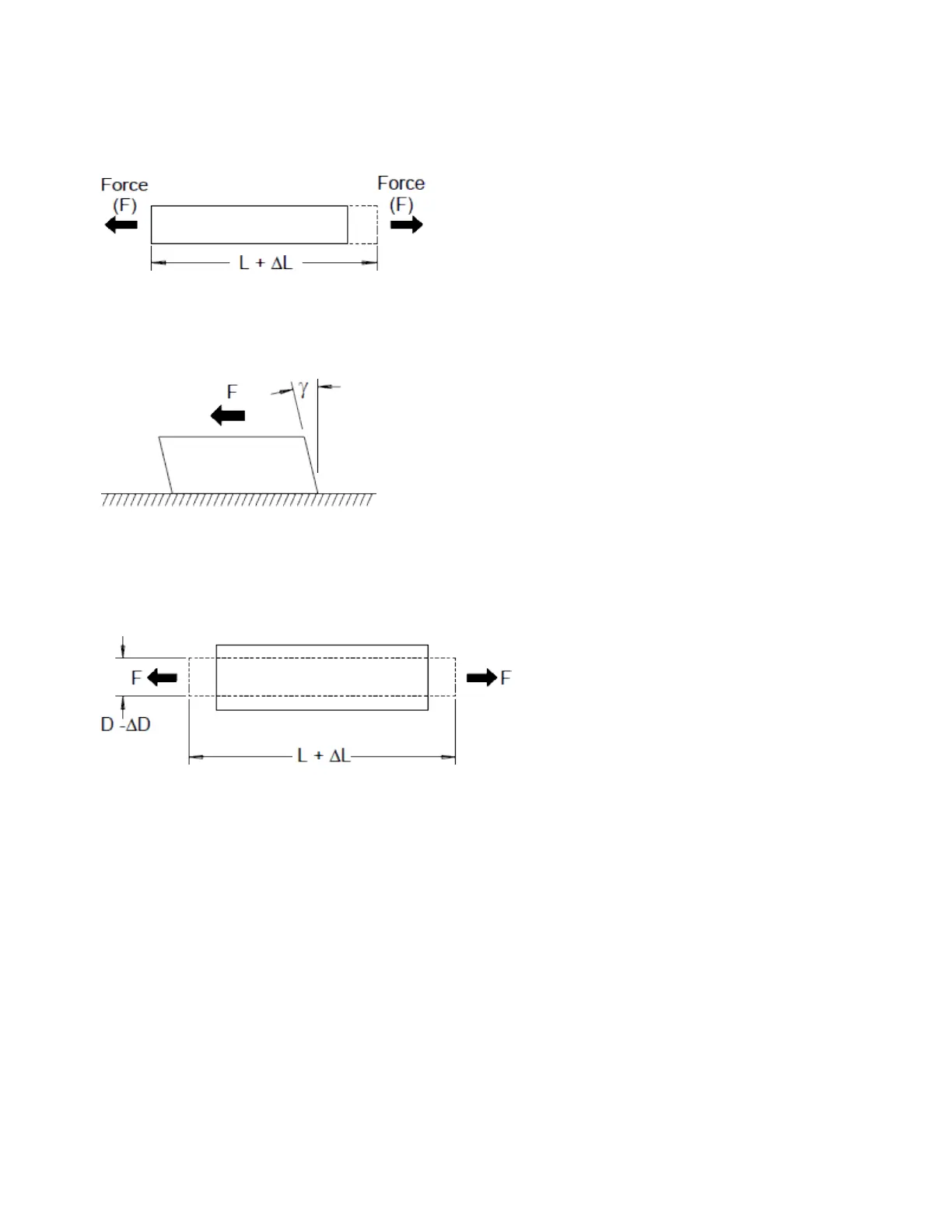

common types of strain measurements as shown below:

Normal strain (ε) is a measure of the deformation along the axis of the applied force, where ε=ΔL/L

Shearing strain (γ) is a measure of the angular distortion of a body. It is approximated by the tangent of the

angle formed by the angular change between two line segments that were parallel in the undeformed state.

Poisson Strain (υ) measures a property of materials known as the Poisson Ratio. It is the negative ratio of

transverse and longitudinal normal strain when a body has a longitudinal tensile force applied, where υ = -

ε

t

/ε, where ε

t

= ΔD/D and ε = ΔL/L

Stress Stress is a term used to compare the loading applied to a material with its ability to carry the load.

Stress (σ) in a material can not be measured directly; it must be computed from material properties and

measurable quantities such as strain and force.

Strain Sensors The metal foil resistance strain gage is by far the most widely used strain measurement

sensor. It consists of a thin metallic foil grid bonded to a thin insulating, adhesive backing. The resistance

of the foil varies linearly with strain. Strain in the test body is simply the ratio of the foil’s strained to

unstrained resistance: ε = ΔR / R.

The Gage Factor (GF) indicates the sensitivity of a strain gage and is a measure of the fractional resistance

change per strain: GF = (ΔR / R) / ε. Devices with a higher gage factor will exhibit a greater resistance

change per strain applied.

Strain gages are available in various numbers and configurations of elements. The most common element

is the single gage form shown below. Multi-element strain gages, also called rosettes, are used to measure

Keysight DAQ970A User's Guide 207

4Measurement Tutorials

Loading...

Loading...