components of strain in different directions. Two-element (90°) and three-element (45° or 60°) con-

figurations are the most common.

Common Uses for Strain Gages Strain gages are used to sense many types of physical parameters.

Strain gages are primarily a force-sensing device. Force is measured indirectly by measuring the deform-

ation of a test body to a known applied force thus producing a resistance change proportional to the

applied force. Many other physical quantities can be measured through force measurements. Common

applications of strain gages include weight, pressure, flow, and level measurements.

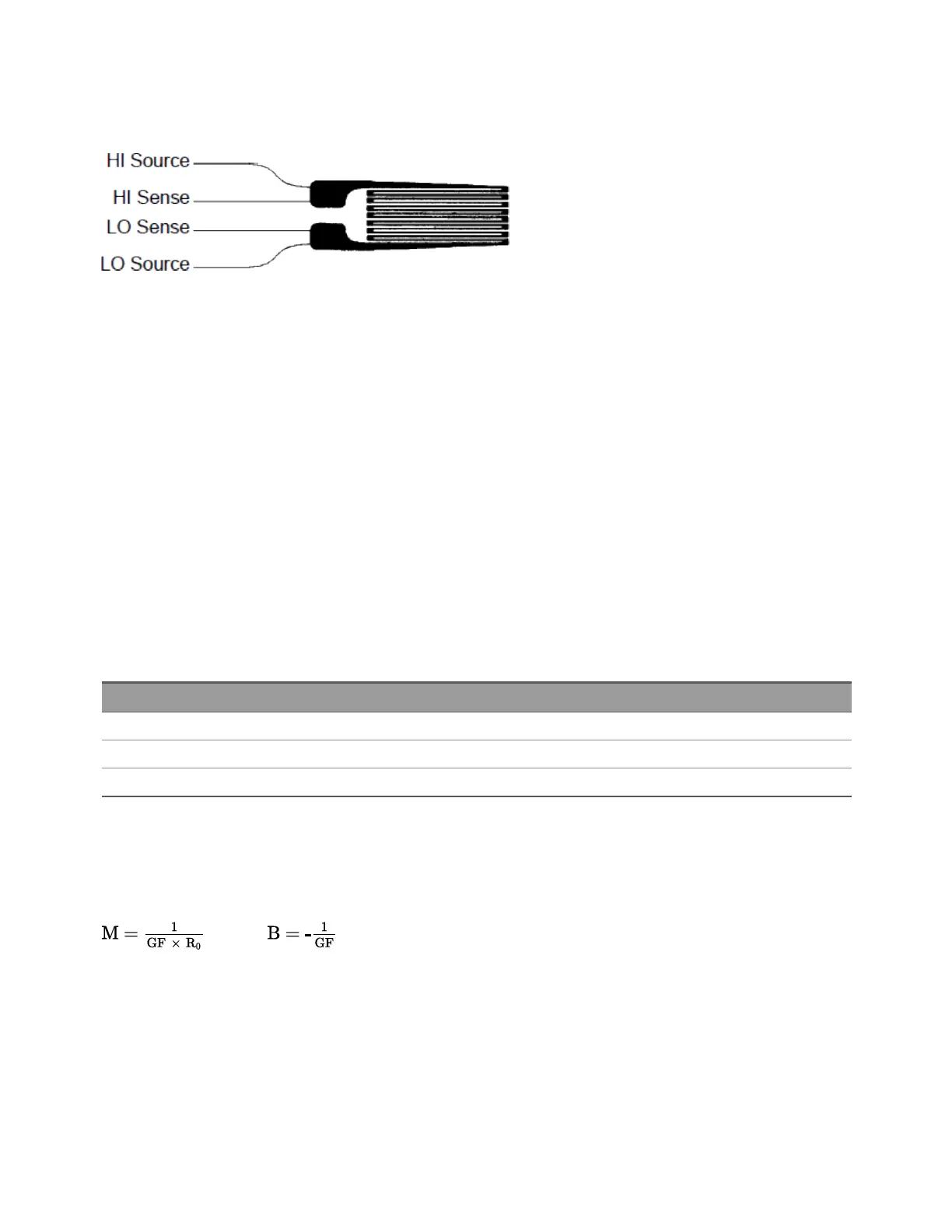

Making Strain Gage Measurements A Wheatstone bridge is commonly used to enable instruments with

low-sensitivity measuring capabilities to measure small resistance changes common in strain meas-

urements. Instruments with high-resolution resistance measuring capabilities, like the DAQ970A internal

DMM, can directly measure small resistance changes with high precision and linearity. You should also use

the 4-wire resistance method when measuring strain gages to eliminate system cabling errors.

An initial, unstrained, gage resistance measurement is used as the reference (R

0

) measurement from which

strain (ΔR / R0) is measured. For best results, you should perform this reference measurement after the

strain gage has been mounted to the test body. The table below shows the resistance changes cor-

responding to 1 µε strain for common gage factor and unstrained gage resistance values.

Strain GF R

0

ΔR DMMSensitivity

1 µε 2.0 120 Ω 0.24 mΩ 0.1 mΩ (0.4 µε)

1 µε 2.0 350 Ω 0.70 mΩ 1.0 mΩ (1.4 µε)

1 µε 2.0 1000 Ω 2.0 mΩ 1.0 mΩ (0.5 µε)

Using the measurement scaling function (mX+b) with the equations shown below will allow you to display

results directly in strain on the DAQ970A front-panel display. You can use a custom measurement unit to

display readings in “µε” (micro-strain) directly. The instrument will automatically add the micro (“µ”) prefix

based upon actual calculated values.

Temperature Effects The resistive element of a strain gage will produce a resistance change ΔR due to

measured strain as well as changes in gage temperature. This will create an “apparent” strain change

which is undesirable. A second gage of similar type can be used to detect temperature changes and thus

remove this error source. You should mount the second gage in close proximity and at 90° to the first

gage, thus responding to local temperature changes but rejecting strain changes. Subtracting meas-

urements from the second gage will remove any undesirable strain errors.

4Measurement Tutorials

208 Keysight DAQ970A User's Guide

Loading...

Loading...